Ames Procedures

and Guidelines

APR 8715.1

Effective Date: 12/12/2012

Expiration Date: 12/12/2017

COMPLIANCE IS MANDATORY

NASA Ames Health and Safety Manual

Chapter 17 - Lifting Devices and Equipment

17.1 Responsibilities

- All personnel, including contractors, working with or around lifting devices shall follow the requirements of this chapter, Occupational Safety & Health Administration (OSHA), American Society of Mechanical Engineers (ASME), NASA-STD-8719.9 (Standard for Lifting Devices and Equipment) and all other applicable regulations.

- Signatures

- Signing a document demonstrates review of the document to ensure accuracy, completeness and/or concurrence when multiple signatures are required.

- Signing where approval is indicated on a document demonstrates review and consent to move forward.

17.1.1 Center Director

- The Center Director shall:

- Designate in writing at least one person and one or more alternates as the Ames Lifting Device Equipment Manager (LDEM) with appropriate background in lifting devices, lifting operations, lifting equipment industry standards and an understanding of lifting safety.

- Designate in writing at least one representative and alternate from each Directorate that uses lifting devices to be an active member of the Lifting Device Equipment Committee.

17.1.2 Safety, Health & Medical Services Division

- The Occupational Safety, Health and Medical Services Division shall:

- Review and evaluate Critical Lift Plans and associated documents.

- Assist with support of the Ames Lifting Device Equipment Committee.

- Perform audits and reviews with the aid of the Lifting Device Equipment Manager (LDEM).

- Monitor compliance to NASA policies and all applicable governing regulations, laws and guidelines that pertain to lifting devices and equipment.

- Document inspection findings and recommendations for improvement in lifting devices and equipment safety procedures resulting from mishap investigations or hazard reports using the Ames Safety Accountability Program (ASAP) or approved system.

- Assist and support the Lifting Device Equipment Manager (LDEM) to develop policies and procedures that meet NASA, Occupational Safety and Health Administration (OSHA), American Society of Mechanical Engineers (ASME) and the National Commission for the Certifications Crane Operators (NCCCO) examination requirements.

- Provide a training program that meets NASA-STD-8719.9 (Standard for Lifting Devices and Equipment) and OSHA regulations for the operation of overhead cranes, aerial platforms and powered industrial trucks.

- Provide support for review and evaluation of non-critical lift projects as requested.

- Perform periodic license checks of crane operators & riggers to ensure they have physical license in their possession.

- Revoke licenses for negligence, violations of safety requirements or failure to meet medical standards by collecting the card or contacting the holder in writing and then returning the card to the QH Training Coordinator along with the reason for revocation. The supervisor is to be notified of the revocation in writing.

17.1.3 Ames Research Center Health Unit

Shall perform medical certification examinations for NASA Employees as specified in applicable NASA directives.

17.1.4 System Safety and Mission Assurance Division

- The System Safety and Mission Assurance Division shall:

- Upon request, review and evaluate Critical Lift Plans and associated documents.

- Document nonconformance, noncompliance, and corrective action tracking in applicable electronic databases, such as the Ames Continuous Improvement Action System (CIAS).

- Support and evaluate hazard analysis on lifting device equipment used for critical lifts as specified in NASA-STD-8719.9 (Standard for Lifting Devices and Equipment).

17.1.5 Lift Project Manager

- Lift Project Managers shall:

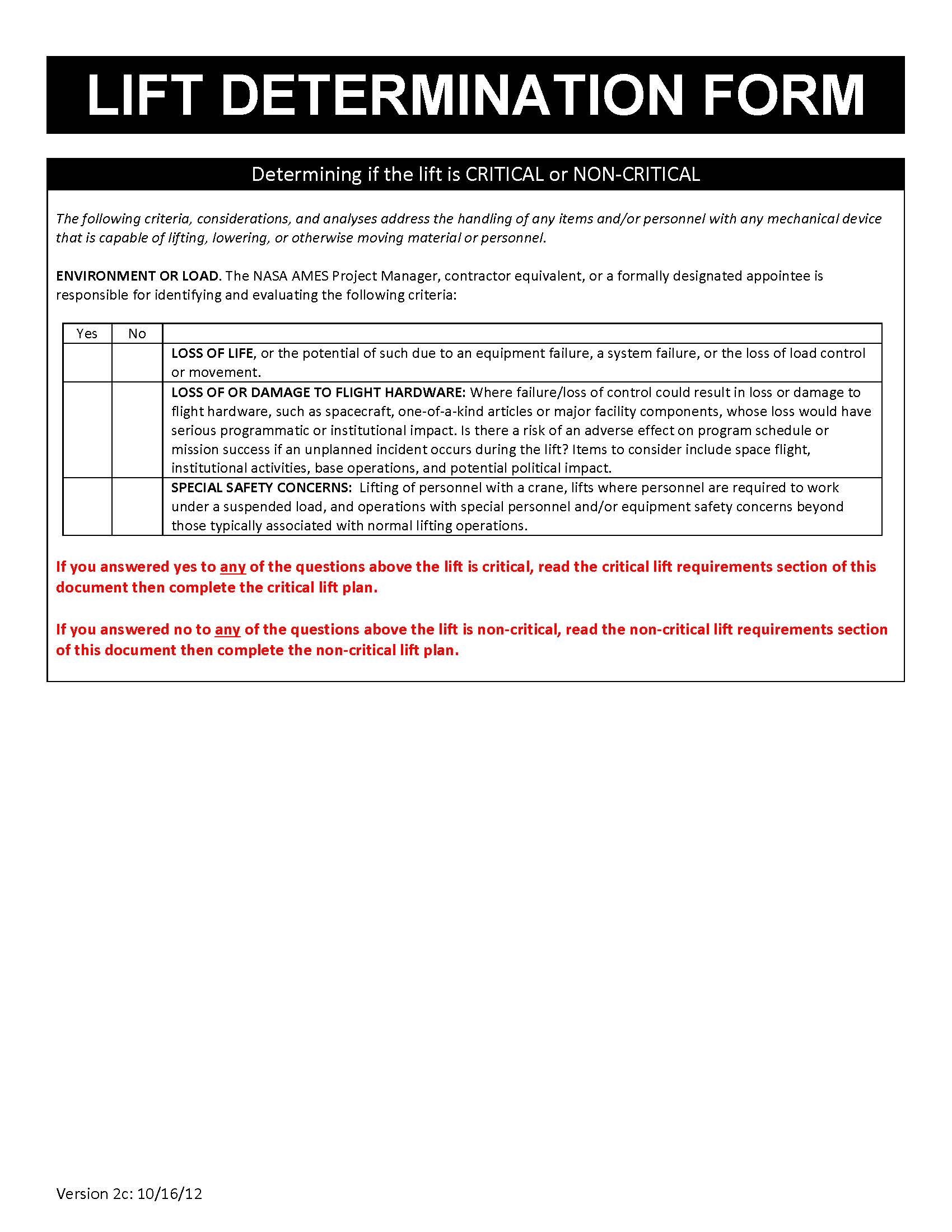

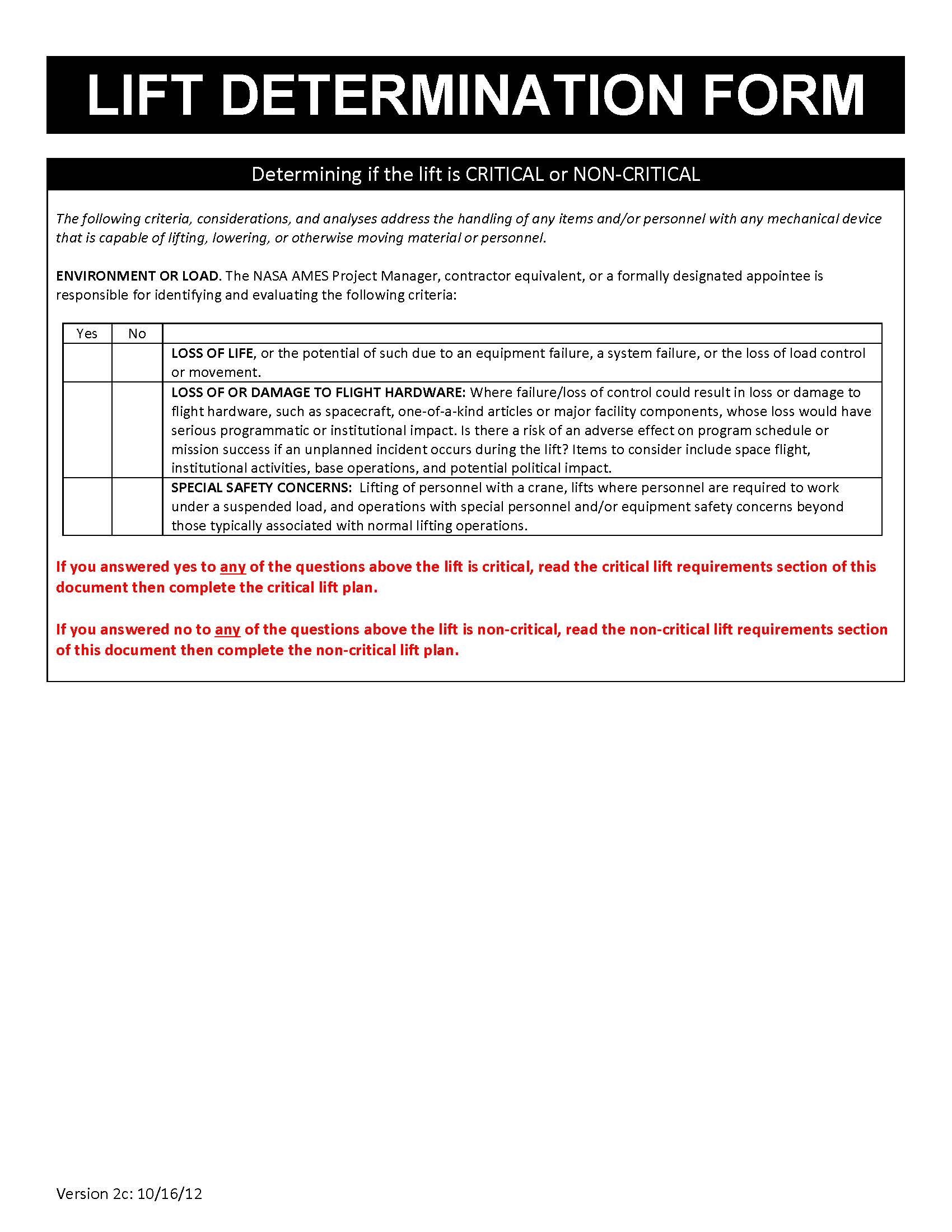

- Determine the process to identify type of lift using the Lift Determination form in the appendix.

- Ensure that all lifts are conducted in accordance with NASA policies and all applicable regulations.

- Include in contracts the appropriate requirements for safety performance and written safety plans, such as those in NASA Specification Section 01 35 26, (General Safety Requirements).

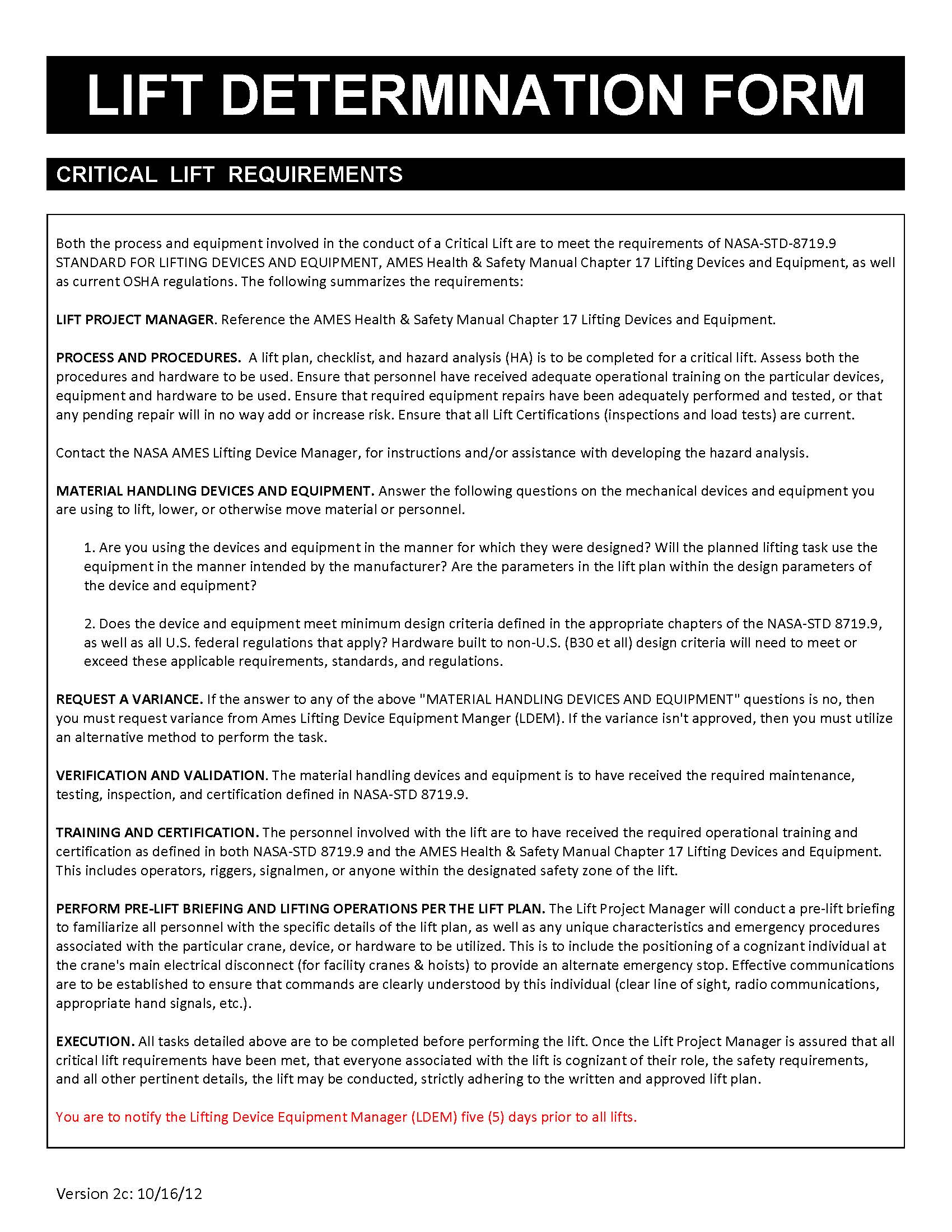

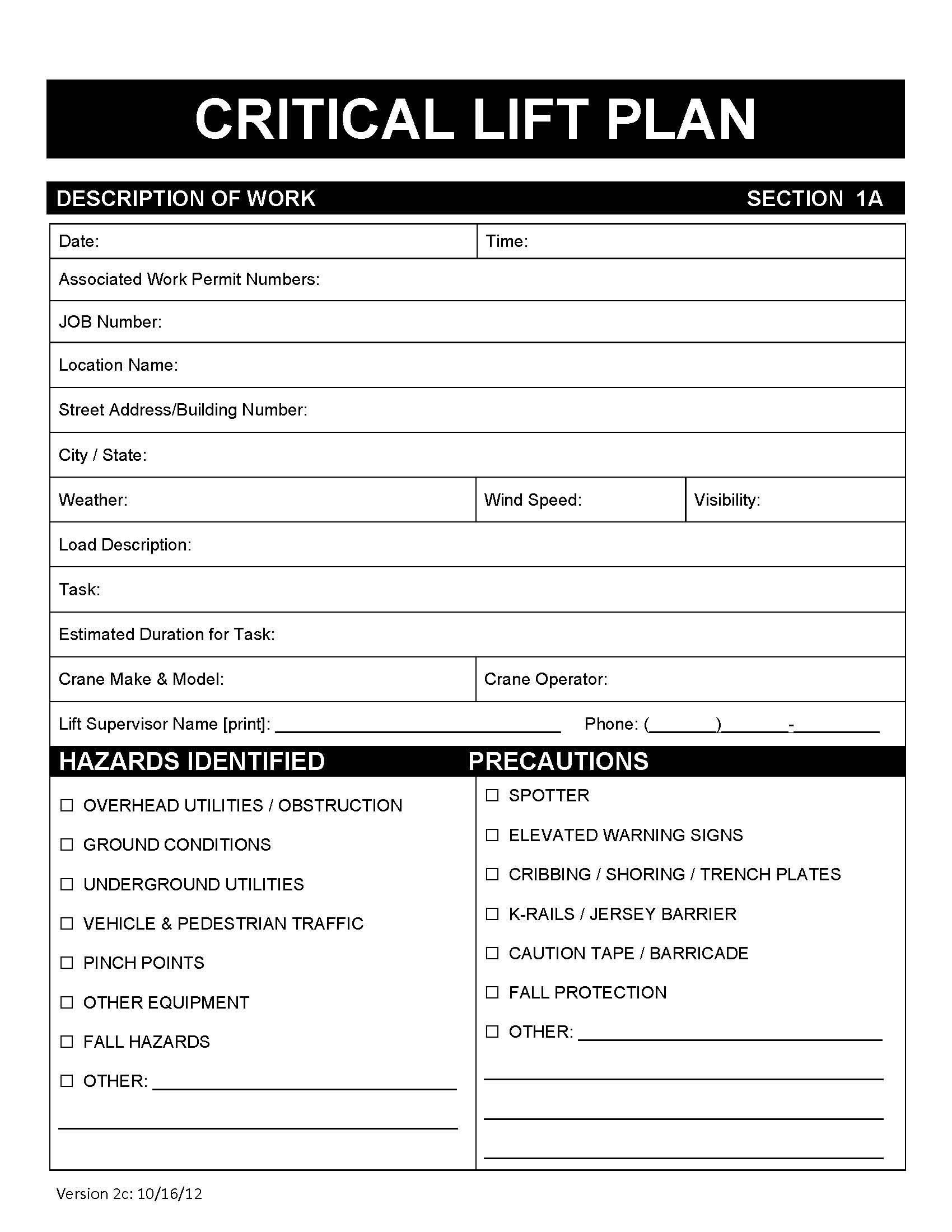

- Ensure that the "Lift Plan" for critical lifts is not issued until an engineer approves the lifting plan in writing. The evaluation must include specifications and calculations of all lift hardware and loads at a minimum.

- Appoint an individual (NASA or contractor) who shall be present as the Safety Lift Observer (SLO) during each critical lift and designated as responsible for the safety of the operations. That person may be the LDEM or a safety professional, a supervisor, an engineer or a task leader, provided he or she has appropriate training and background in lifting operations with an understanding of lifting safety.

- Submit lift plan for approval prior to conducting crane lifting activities or all critical lifts (includes forklift, manlift, all other lifting devices and equipment).

- Inform the LDEM of any installations, maintenance, and/or other improvements to any lifting devices and equipment at Ames Research Center within six (6) months of purchase.

- Notify the LDEM and Safety, Health & Medical Services division of all planning meetings when a critical lift plan has been received.

- Ensure that a lifting procedure and safety hazard analysis are developed for all critical lifts including the lifting of personnel. Provide copies to the LDEM and the Safety, Health & Medical Services Division prior to the critical lift review meeting.

- Ensure that a safety meeting is held with in 5 business days prior to each lift.

- Revew each non-critical lift to determine if an engineer is needed to approve the specifications of all lift hardware and loads prior to conducting a lift.

- Ensure that all mobile crane lifts have an engineering load evaluation as part of the approval process. The evaluation must include specifications and calculations of all lift hardware and loads at a minimum.

- Be appointed by the supervisor within each directorate, organization or program office for an individual lift. The Lift Project Manager can be a Civil Servant or Contractor.

17.1.6 Code JA, Acquisition Division

- Code JA, Acquisition Division shall:

- Require that all contracts for mobile crane services include a copy of NASA-STD-8719.9 (Standard for Lifting Devices and Equipment).

- Inform the LDEM of any installations, maintenance, and/or other improvements to any lifting devices and equipment at Ames Research Center within six (6) months of purchase.

- Invoke the "Suspension of Work" provision of the contract should the Contractor or subcontractors refuse or fail to ensure prompt corrective action of any noted safety deficiencies.

17.1.7 Code JCM, Plant Engineering Branch

- Code JCM, Plant Engineering Branch shall:

- Designate a qualified individual to serve as the Center's Lifting Device Equipment Manager (LDEM). This designation will be in writing.

- Ensure that the LDEM is responsible for oversight of lifting devices, maintenance and equipment programs and coordination with appointed personnel on all lifting issues through monthly documented program audits. See Maintenance & Inspection Program section of this document.

- Ensure the LDEM receives all notices of lifting operations and contractual documentation from outside vendors and contractors of proposed lifting projects for both critical and non-critical lifts.

- Ensure that the LDEM reviews information on new lifting device equipment purchased within the first six (6) months for compliance with all design/hardware aspects of NASA-STD-8719.9 (Standard for Lifting Devices and Equipment).

- Ensure that the LDEM submits Lessons Learned to the NASA Ames Lessons Learned Administrator within thirty (30) days after conclusion of investigation for mishap or close calls to be published in the NASA HQ Lessons Learned system. See the Lessons Learned section in this chapter for additional information.

17.1.8 Lifting Device Equipment Manager and Alternate

17.1.8.1 The Lifting Device Equipment Manager shall:

- Maintain oversight of the Alternate Lifting Device Equipment Manager activities and responsibilities.

- Promptly report to the Center Director when any ORG with lifting devices does not have a representative assigned to the Lifting Device Equipment Committee for a period of more than thirty (30) days.

- Participate as a member of the Lifting Device Equipment Committee providing Ames' position on lifting devices and equipment safety issues.

- Serve as the chair of the Lifting Device Equipment Committee.

- Have joint responsibility for the enforcement of the Ames lifting device and equipment program, including Powered Industrial Trucks, Mobile Aerial Platforms, and Jacks with the Ames Safety, Health & Medical Services Division.

- Ensure that annual inspection, documentation and certification of cranes has been completed.

- Provide technical coordination and relative support with regards to cranes, critical and non-critical lifts, lifting operations, qualification of operators and supervisors, reviews safety variances.

- Assist in the training qualification process for crane operators, riggers & signal persons through the Ames Health, Safety & Medical Services Division training program.

- Submit Lessons Learned information to the NASA Ames Lessons Learned Administrator within thirty (30) days after conclusion of investigation for mishap or close calls to be published in the NASA HQ Lessons Learned system. See the Lessons Learned section in this chapter for additional information.

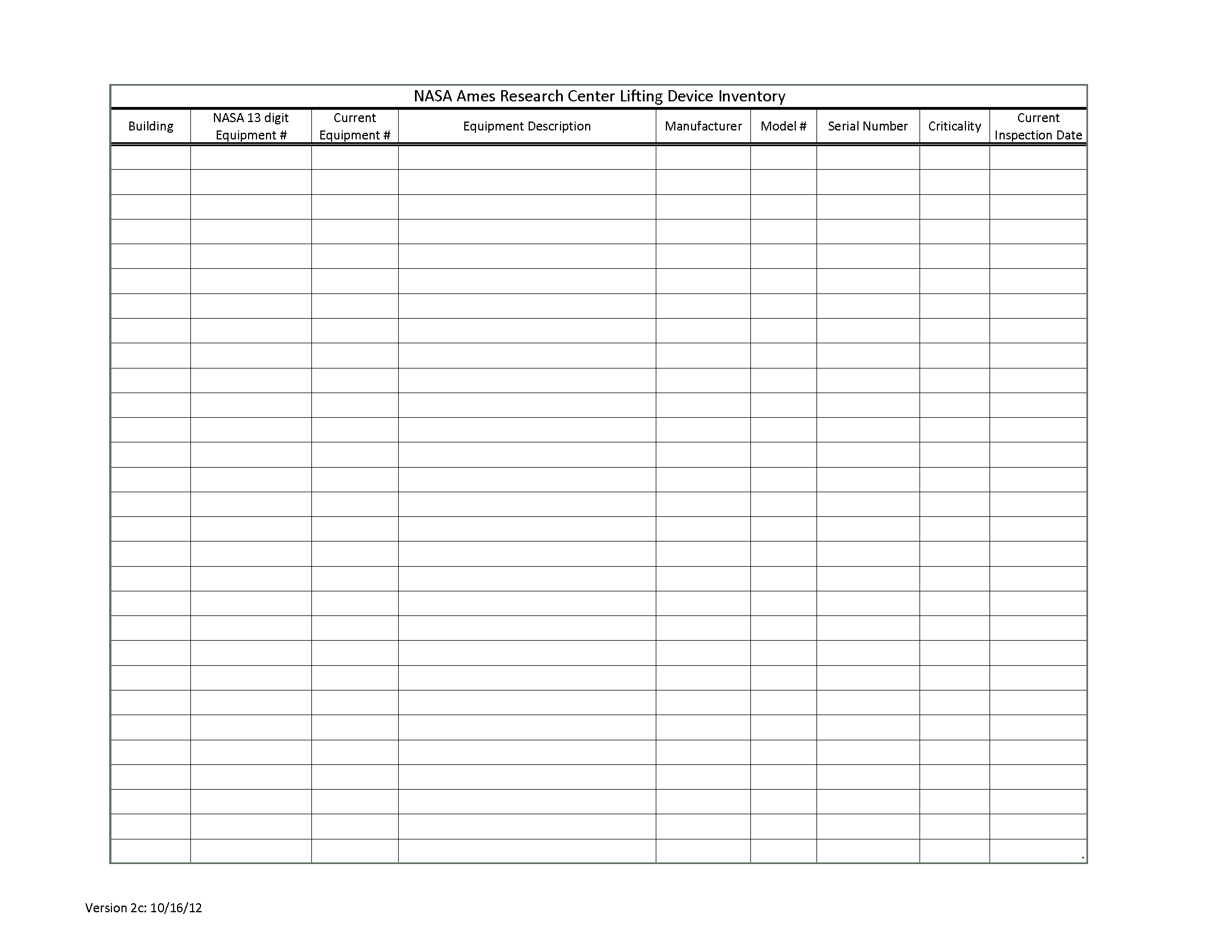

- Manage an inspection program for lifting equipment, using an inventory status report provided by equipment owners and organizations using lifting equipment.

- Establish and maintain records in the Ames Management System to include procedures for the maintenance and calibrating of equipment that is used to load test lifting devices and equipment. These records will be kept on file for the life of the lift equipment or device.

- Document proof and load tests of overhead cranes and maintain associated calibration records for the life of the crane.

- Maintain oversight responsibility for program through monthly documented program audit to ensure annual inspection and periodic load test have been conducted. (see the Maintenance & Inspection Program section for additional information)

- Provide an annual report to the Lifting Device Equipment Committee on the status of each organization that owns lifting devices and equipment in efforts to inventory and provide records regarding the tagging and inspection of each critical and non-critical lifting device in accordance with NASA-STD-8719.9 (Standard for Lifting Devices and Equipment). These records will be on file for the life of the lifting equipment and/or device.

- Manage the Maximo or system and document the process.

- Ensure non destructive testing (NDT) of overhead cranes is conducted and documented when it is required for the periodic load test.

- Ensure that all lifts are conducted in accordance with NASA policies and all applicable regulations.

- Maintain rigging hardware periodic load test reports for a minimum of two test cycles.

17.1.8.2 The Alternate Lifting Device Equipment Manager shall:

- Perform responsibilities of the LDEM in their absence (see LDEM responsibilities section).

- Ensure that the Lifting Device Equipment Manager (LDEM) reviews information on new lifting device equipment purchased within the first six (6) months for compliance with all design/hardware aspects of NASA-STD-8719.9 (Standard for Lifting Devices and Equipment).

- Have joint responsibility for the enforcement of the Ames Lifting Device and Equipment program, including Powered Industrial Trucks, Mobile Aerial Platforms, and Jacks with the Ames Safety, Health & Medical Services Division.

- Conduct and document monthly program audits to ensure annual inspection and periodic load test have been conducted (see the Maintenance & Inspection Program section for additional information).

17.1.9 Lifting Device Equipment Committee

- The Lifting Device Equipment Committee shall:

- Develop a charter for the NASA Ames Research Center (ARC) Lifting Device Equipment Committee to ensure this chapter and NASA-STD-8719.9 (Standard for Lifting Devices and Equipment) is understood and applied across other organizations at NASA Ames.

- Meet to discuss specific center requirements and/or needs such as variances or pick plans.

- Provide a forum to resolve to any issues and exchange information.

- Have representation for each organization within NASA Ames that are responsible for and/or involved with lifting device equipment.

- Keep meeting minutes, an attendance sign-in sheet and submit minutes for publication on the Lifting Device Equipment Committee web page within thirty (30) days.

- Meet to discuss and develop Lessons Learned from close calls and mishaps at NASA Ames.

17.1.10 Supervisors or Leads

- A supervisor or appointed designee who manages overhead cranes, mobile cranes and derricks, hoists and winches, hooks, hydra-sets and load measuring devices, mobile aerial platforms, powered industrial trucks, and jacks used to lift or support flight hardware and employees who operate such devices or equipment shall:

- Verify conformance to design requirements of NASA-STD-8719.9 (Standard for Lifting Devices and Equipment), ASME B30 series.

- Ensure that periodic load tests and operational tests of their lifting devices and equipment in accordance with the test requirements are completed.

- Ensure that lifting devices are maintained and inspected annually.

- Secure lifting equipment and hardware that is not properly maintained or tested in locked storage with restricted access to prohibit anyone from using. See Rigging & Hardware General Requirements section.

- Ensure that lifting equipment has been properly labeled and tagged as specified in NASA-STD-8719.9 (Standard for Lifting Devices and Equipment) and this chapter.

- Ensure that operation of overhead cranes, mobile cranes and derricks, hoists and winches, hooks, hydra-sets and load measuring devices, mobile aerial platforms, powered industrial trucks, and jacks used to lift or support flight hardware are conducted as specified in this chapter, OSHA 1926.1400, OSHA 1910.179, OSHA 1910.184, ASME B30 series, Ames Safety Chapter 27 (Construction Safety Management) and NASA-STD-8719.9 (Standard for Lifting Devices and Equipment).

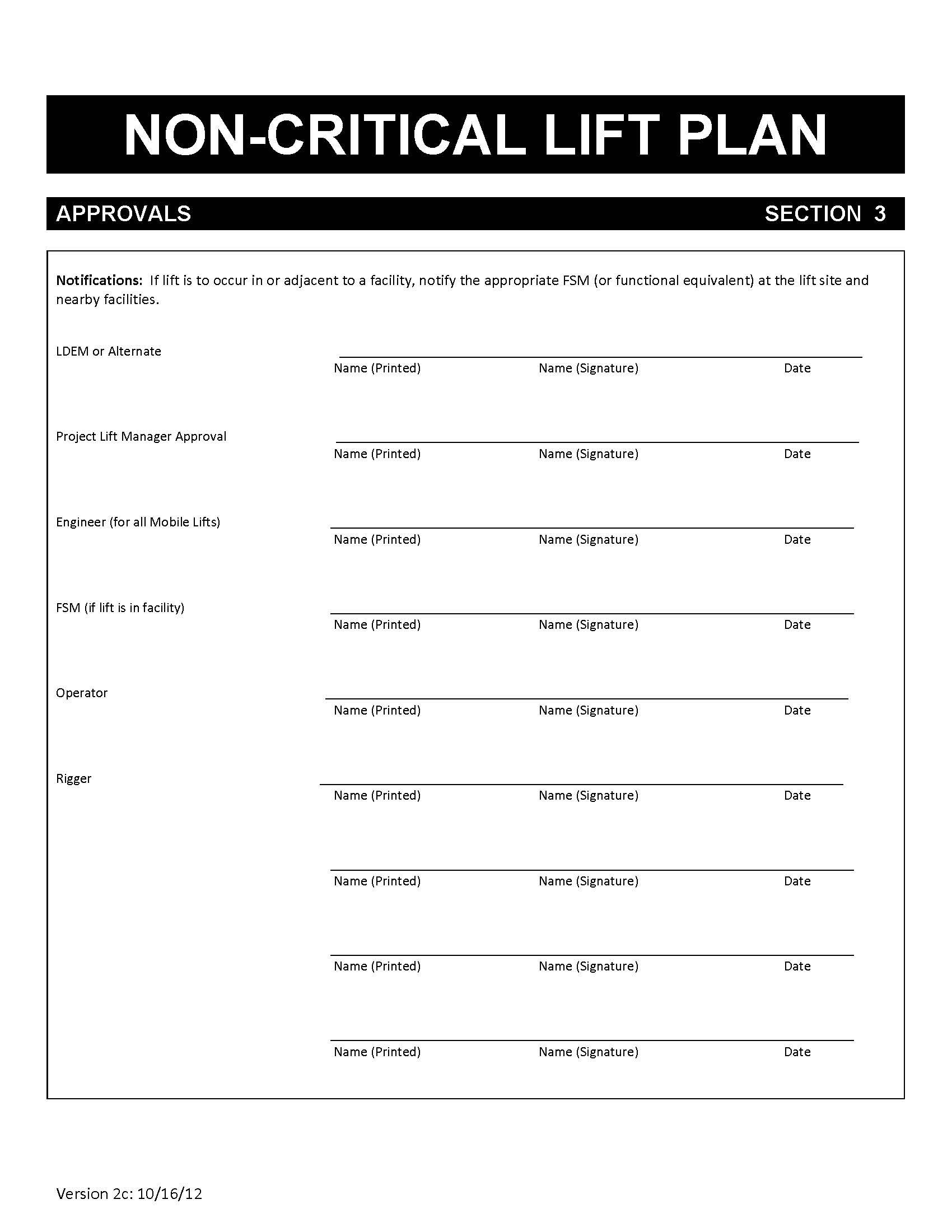

- Ensure that the lift is not performed until all signatures have been obtained and the "Lifting Plan" has been formally approved.

- Ensure that only qualified personnel use lifting devices such as overhead cranes.

- Ensure that only qualified personnel perform rigging or signal duties.

- Arrange for on-the-job training or provide verification as needed (by using the forms provided by the Ames Safety, Health & Medical Services Division) to support Qualified Crane Operator, Rigger & Signal Person status for personnel.

- Conduct and document an annual training review during the month of January for crane operators, riggers, signal persons, forklift and manlift operators.See the General Training Requirements for Lifting Devices and Equipment section of this chapter for additional requirements.

- Maintain rigging hardware periodic load test reports for a minimum of two test cycles.

- Inform the LDEM of any installations, maintenance, and/or other improvements to any lifting devices and equipment at Ames Research Center within six (6) months of purchase.

- Appoint Lift Project Manager within your directorate, organization or program office for an individual lift. The Lift Project Manager can be a Civil Servant or Contractor.

17.1.11 Mobile Lift Contractors

- Contractors who operate cranes or other lifting devices covered by this chapter shall:

- Exercise supervisory authority over all contracted crane operations.

- Ensure that all employees are competent and trained or appropriately qualified for the activities they are conducting by a licensed vocational school or accepted authority.

- Ensure that all employees are fully aware of the hazards associated with the planned lift and all requirements specified in the approved lifting plan.

- Notify the COTR immediately upon discovery of any health and safety deficiency that the contractor cannot resolve immediately.

- Ensure that no deviation from the approved lifting plan occurs without the approval of the responsible Lift Project Manager and an authorized and competent safety person.

- Comply with requirements in this chapter, NASA-STD-8719.9 (Standard for Lifting Devices and Equipment), OSHA and ASME B30 series.

- Submit documentation five (5) business days prior to lift for approval by the LDEM.

- Lift Plan.

- Crane certification.

- Operator and rigger certification.

- Certificate of insurance.

- Certification of rigging hardware.

- Hazard analysis for critical lifts.

- Meet the criteria of the National Commission for the Certification Crane Operators (NCCCO) requirements for certification and qualification status.

- Notify the LDEM and Safety, Health & Medical Services Division of all planning meetings.

17.1.12 Crane Operators, Riggers and Signal Persons

- Crane Operators, Riggers and Signal Persons shall:

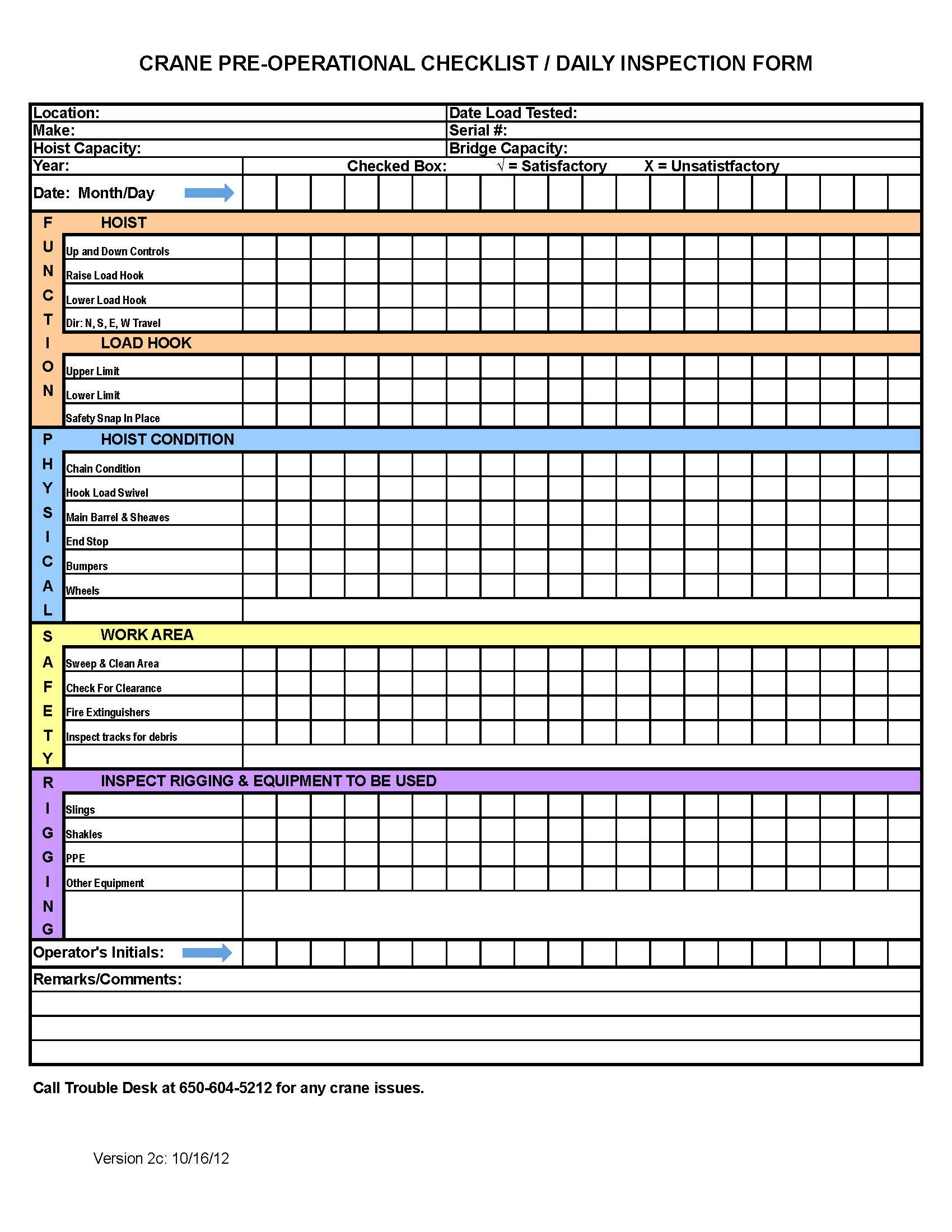

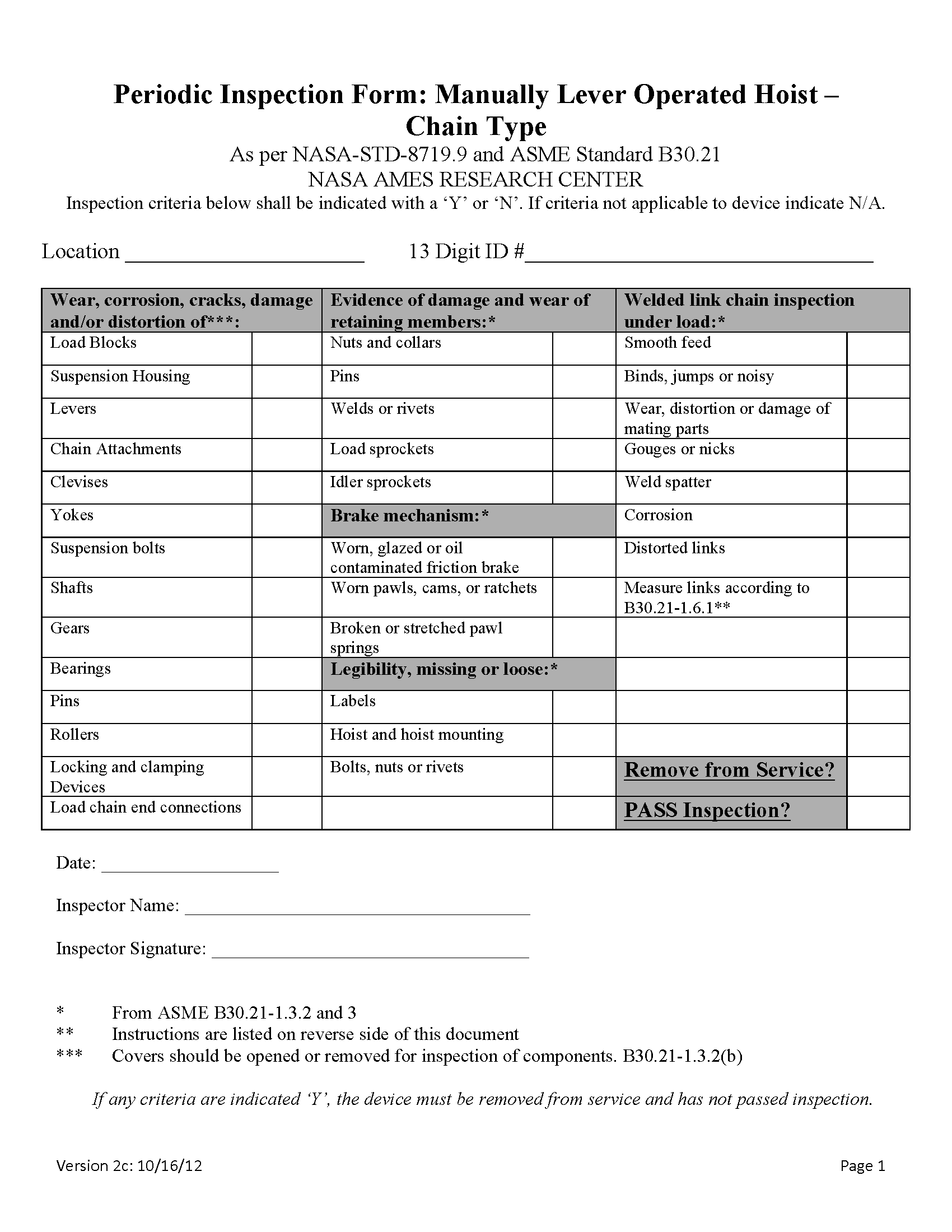

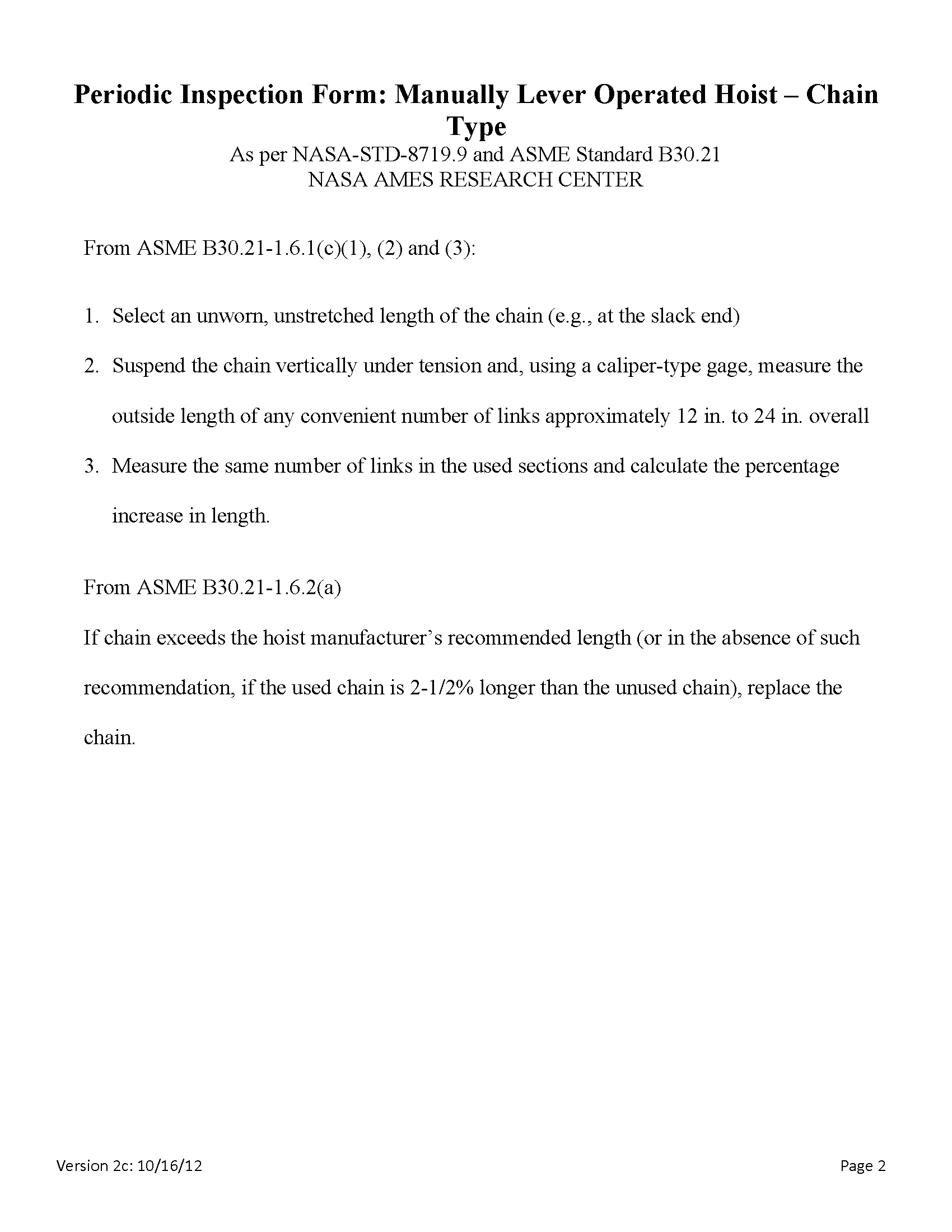

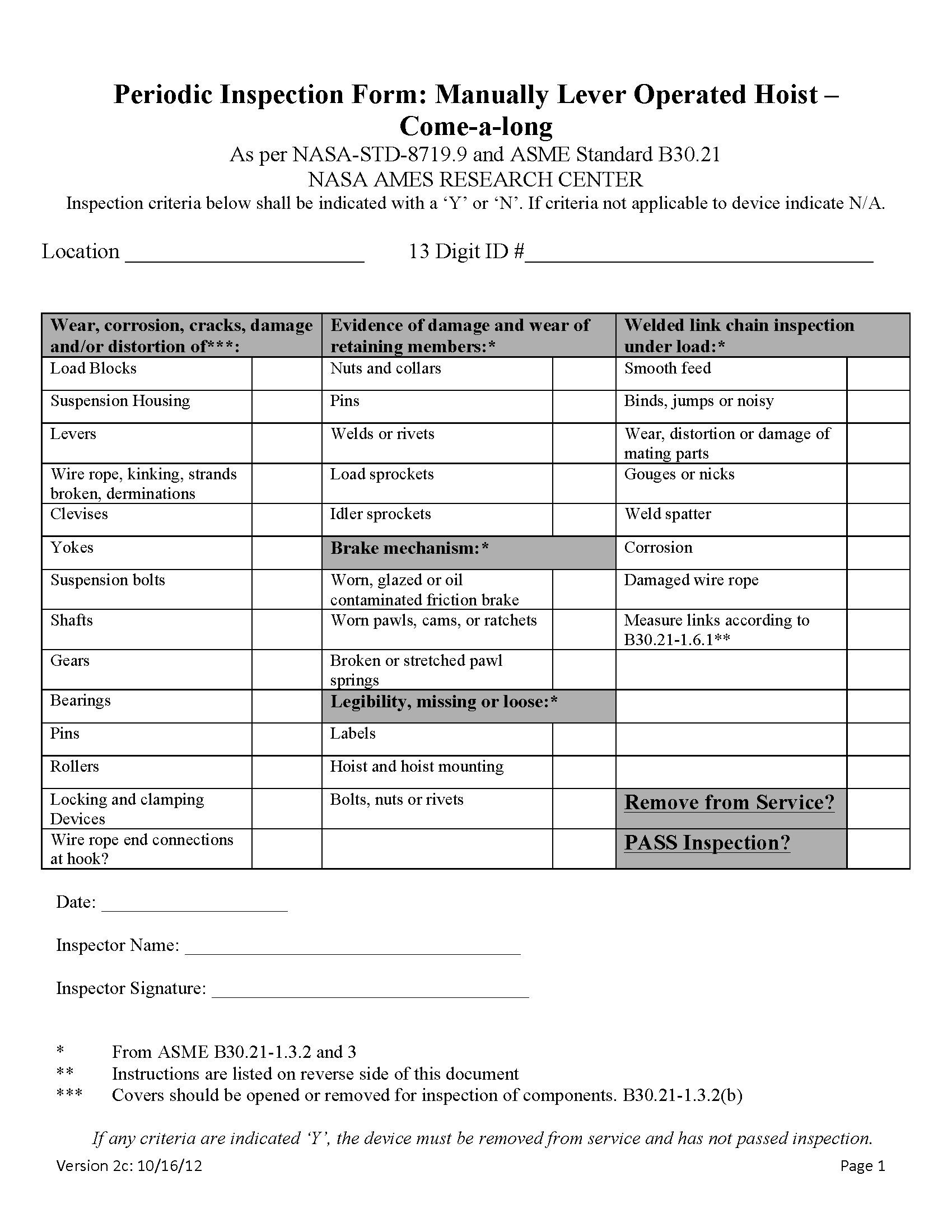

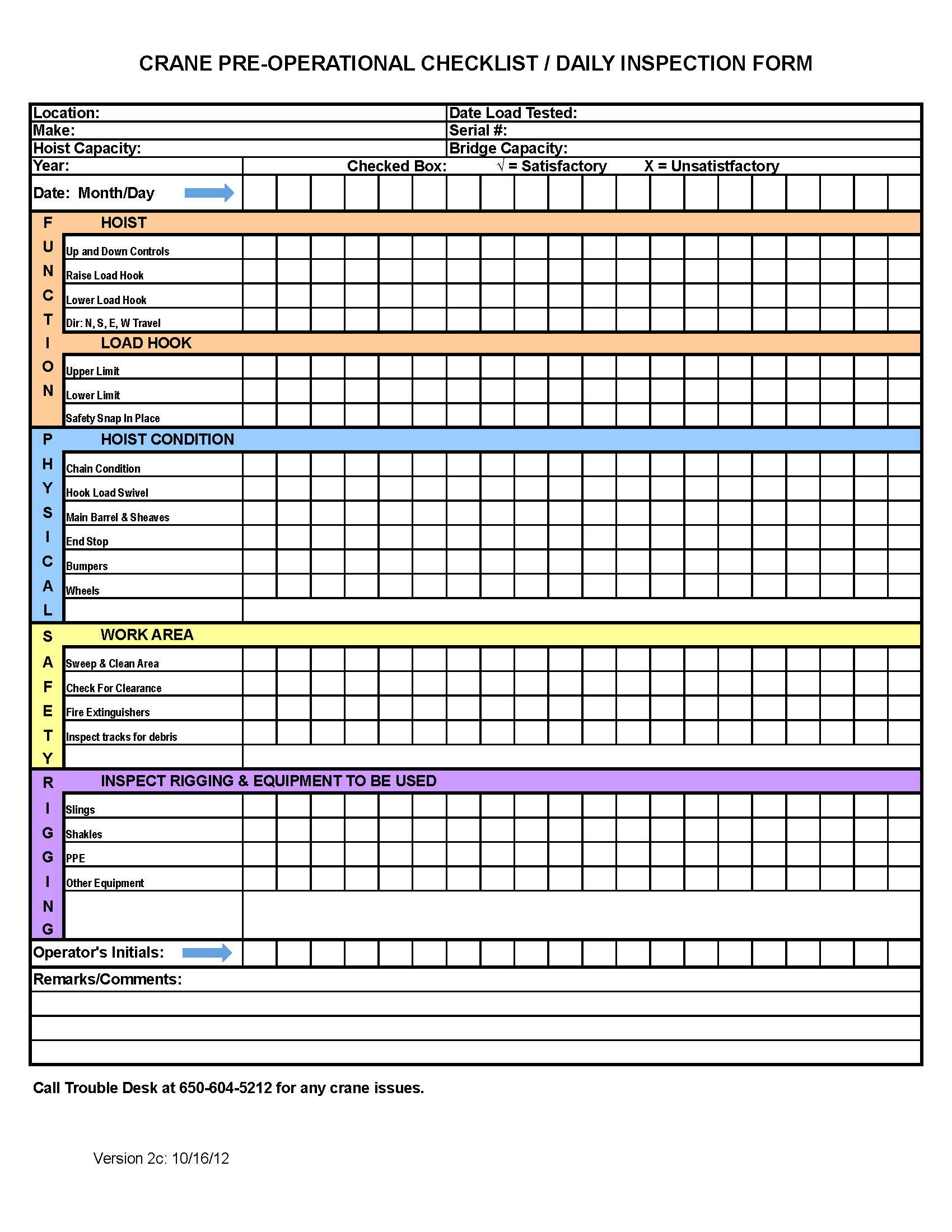

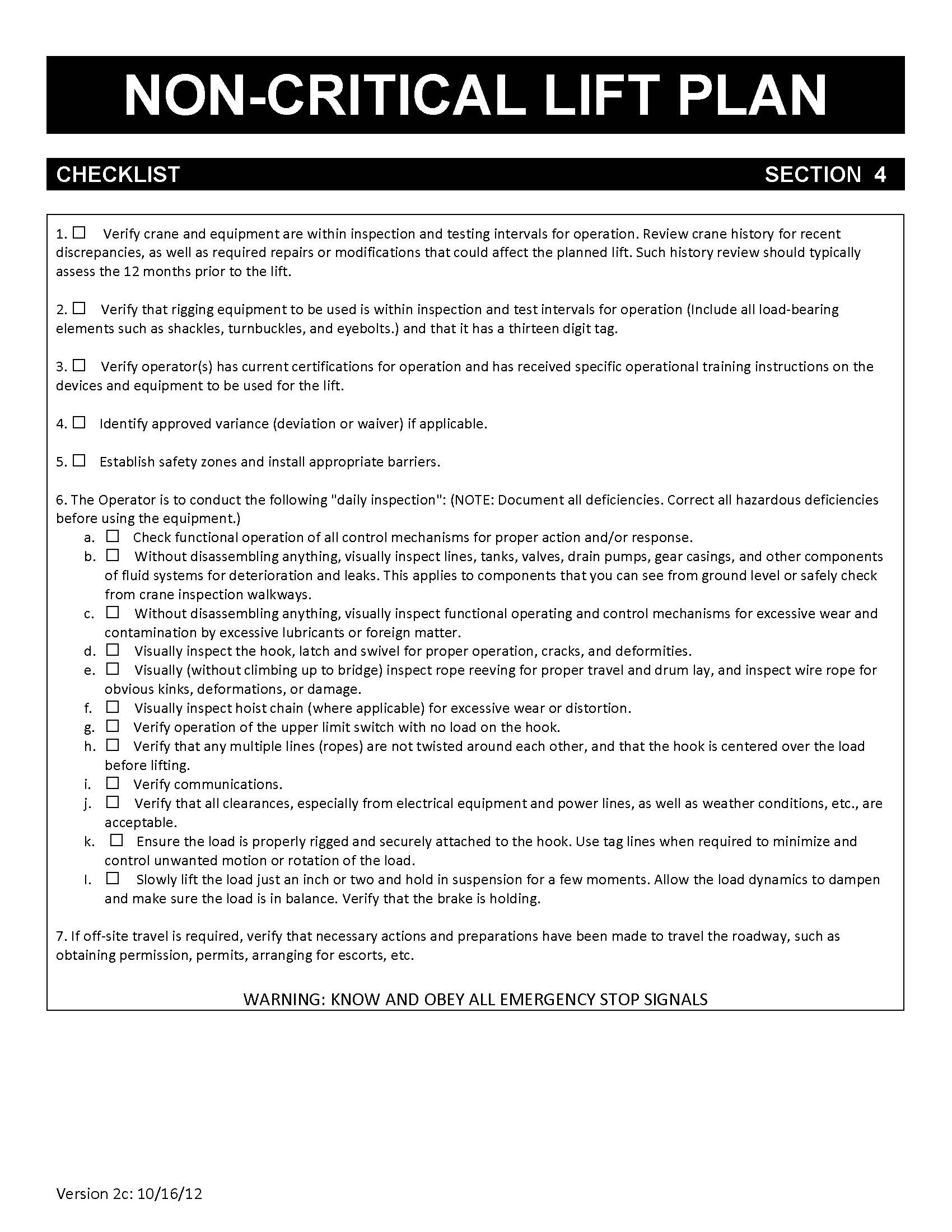

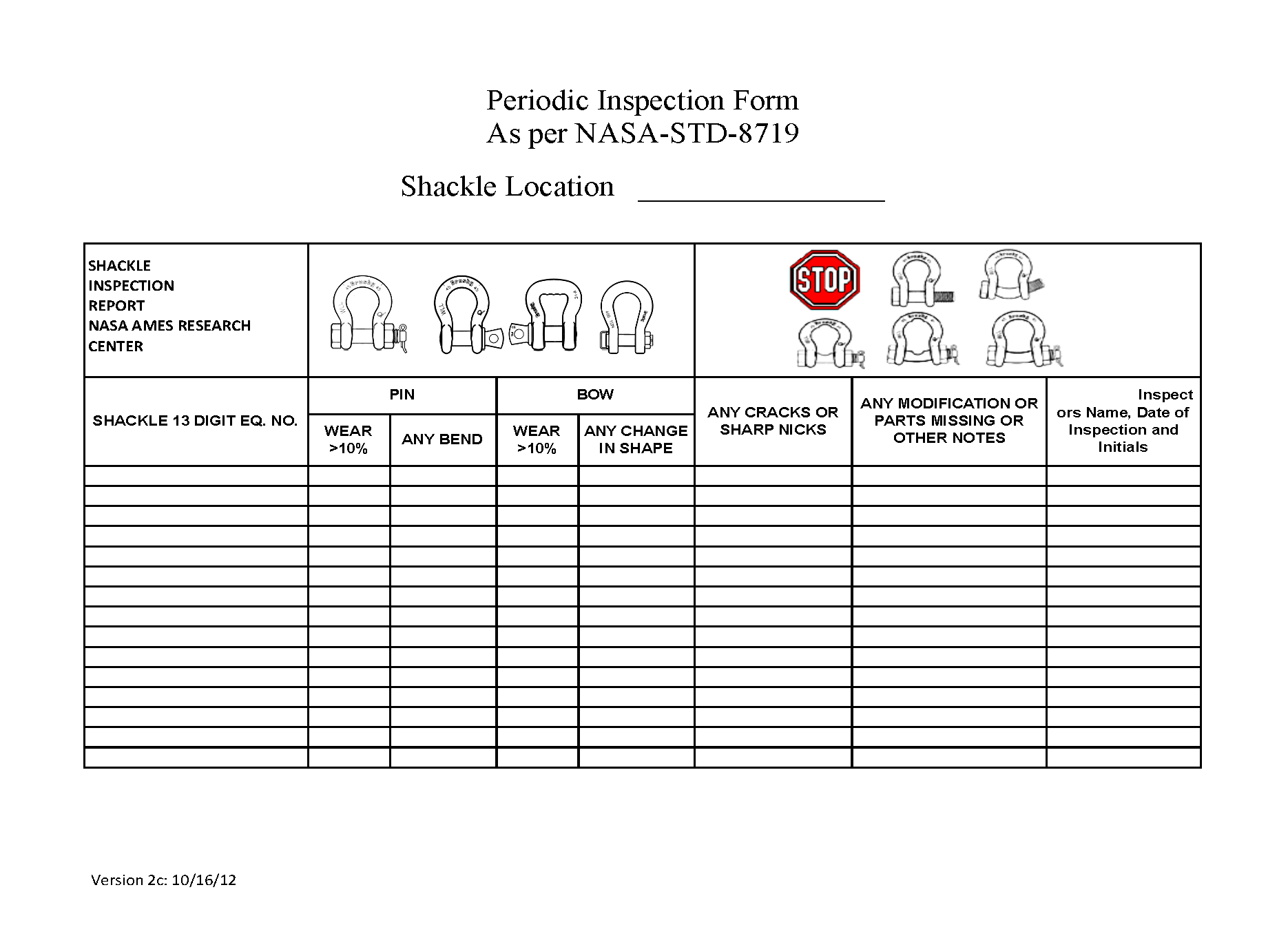

- Inspect then document daily and periodic inspections of cranes, hoists, winches, hooks and all rigging hardware using the approved NASA forms.

- Ensure immediate administrative locking of crane if any deficiencies are identified during inspection. See section (Standard Lockout/Tagout System) of this document.

- Ensure that supervisor takes custody of rigging hardware to secure (or destroy if appropriate) when deficiencies are identified during inspection.

- Maintain inspection documents at a conspicuous location at/near the lift and/or equipment.

- Maintain operator's certification at the Qualified level when performing overhead crane, rigging and signal person duties.

- Complete a medical evaluation for cranes before operating a crane or performing rigging and signal duties to be in good standing and to remain a Qualified lift equipment operator.

- Conduct all lifting actions in a manner that meets the requirements of this document, NASA-STD-8719.9 (Standard for Lifting Devices and Equipment), the Occupational Safety and Health Administration (OSHA) and ASME B30 series.

- Inform the LDEM of any installations, maintenance, and/or other improvements to any lifting devices and equipment at Ames Research Center within six (6) months of purchase.

17.1.13 Personnel Performing Non-destructive Testing (NDT) of Lifting Devices

- Personnel performing lifting devices and equipment nondestructive testing (NDT), including visual inspections, shall be qualified in accordance with written practices meeting the requirements contained in American Society for Nondestructive Testing (ASNT) Recommended Practice No. SNT-TC-1A, Personnel Qualification and Certification in Nondestructive Testing.

[Back to Table of Contents]

17.2 Training

- General training requirements for lifting devices and equipment

- Includes Forklift, Manlift and Overhead Cranes.

- Attend the NASA Ames Training course or an equivalent (as published in the Ames Training Catalog) provided by an industry recognized trainer, training center, or locally developed training program which meets or exceeds industry and OSHA training requirements.

- Complete annual review given by your supervisor during the month of January. This will be done through PowerPoint presentations available to your supervisor via the QH Training Homepage. The supervisor will verify that all currently trained participants for Forklift, Manlift, Overhead Crane Operators, Riggers and Signal Persons have completed the annual review. The supervisor will submit the code QH Annual Lifting Devices and Equipment Training Review Form to the QH Training Coordinator by February 1st of each year for documentation.

- Instructors who provide training shall:

- Review the training curriculum annually then revise as needed to meet regulatory requirements and to include lessons learned.

- Include information specific to NASA Ames operational and procedural requirements.

- Ensure that participants meet medical certification exam requirements defined in NASA Procedural Requirements 1800.1.

- Hold "train the trainer" certification or higher and have prior field experience for the type of class being taught.

17.2.1 Training Certification Levels

- For Qualified Overhead Crane Operators & Riggers there are two levels of proficiency (Critical and Non-critical). Qualified Operator cards are marked with the words “Restriction: Non-critical Only” unless they are authorized for critical lifts and the operator has demonstrated a higher level of proficiency.

- Determination of ability to perform critical lifts is to be made by the instructor during the class hands on evaluation.

17.2.2 Training Requirements for Riggers and Signal Persons

- To become a qualified rigger and signal person the following shall be addressed:

- Classroom training to include the following for non-critical training:

- Principles of rigging safety and operations.

- Lifting equipment emergency procedures.

- General performance standards and requirements.

- Pre-operational checks.

- Safety-related defects and symptoms (for initial certification and as needed).

- Lift hardware and attachment devices.

- Inspections.

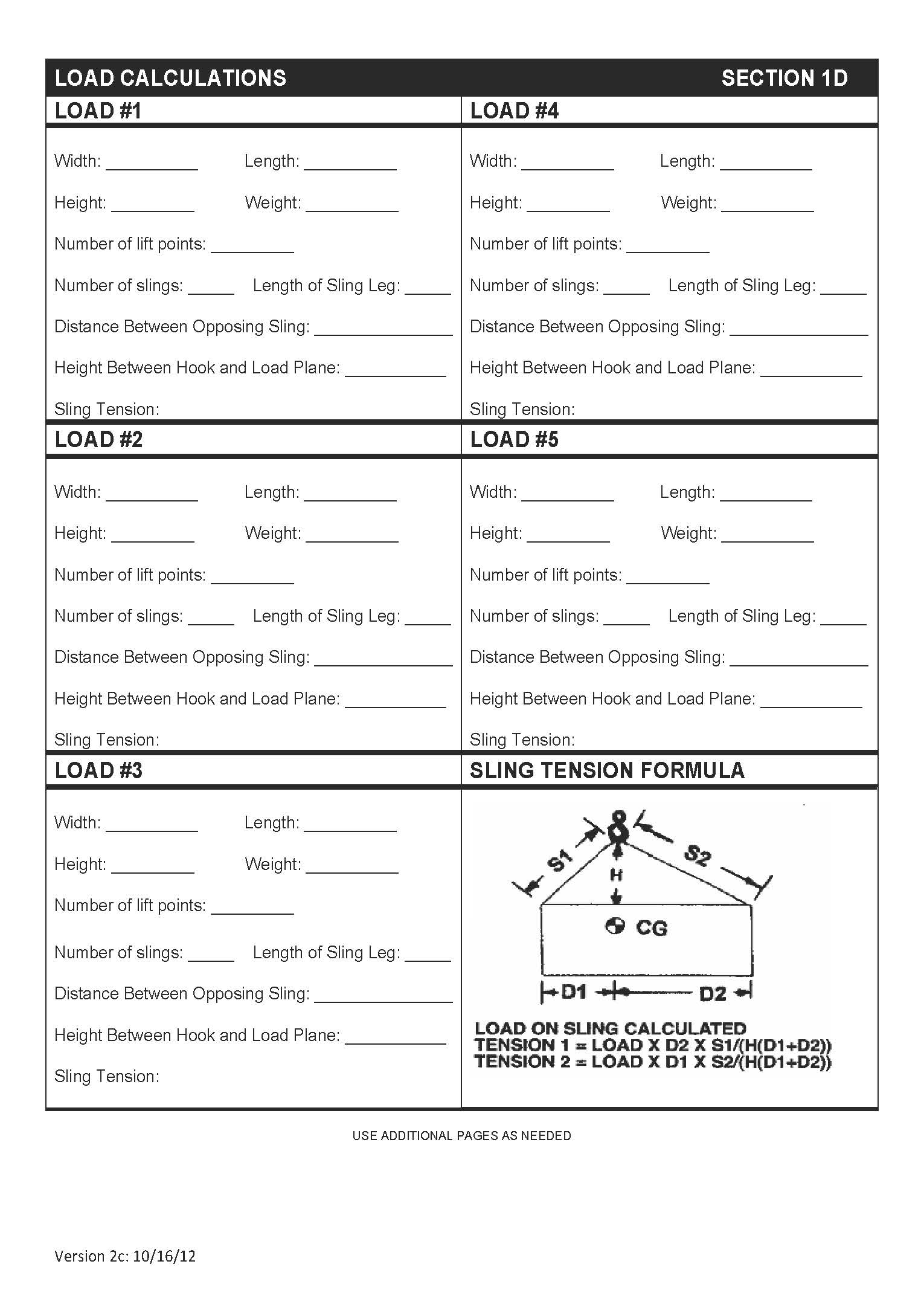

- Load calculations.

- Equipment deficiencies.

- Factors of a safe lift.

- Learn about OSHA, ANSI, NASA Ames, NASA HQ and CMAA requirements.

- Crane accidents that involve rigging and lessons learned.

- Classroom training to include the following for Critical Lift training:

- Specific hazards and special procedures associated with critical lifting.

- Demonstration of proficiency, rigging techniques and methods.

- Physical examination (criteria to be determined by the cognizant medical official consistent with NPR1800.1 and based upon the related requirements associated with performing rigging tasks).

- Written examination with a seventy (70) percent score or better to pass.

- Practical examination for each individual demonstrating the ability to adequately determine and/or apply: load weight, center of gravity, special lifting devices essential to the safe and successful lift operation, proper rigging principals, methods, and techniques using simulated loads of various weights, sizes, and configurations.

- Conducted under the supervision of senior personnel within their own organization. Trainee is allowed to perform rigger and signal person duties only in the presence of senior personnel that currently hold qualified status.

- Verified through the supervisor (using the QH form for Rigger and signal person qualified status) after the trainee has achieved proficiency.

- Training will be due at least every two (2) years.

17.2.3 Training Requirements for Overhead Crane Operators

- To become a qualified overhead crane operator the following shall be addressed:

- Classroom training to include the following for non-critical training.

- Principles of crane safety and operations.

- Lifting equipment emergency procedures.

- General performance standards and requirements.

- Pre-operational checks.

- Safety-related defects and symptoms (for initial certification and as needed).

- Inspections.

- Load calculations.

- Equipment deficiencies.

- Factors of a safe lift.

- Learn about OSHA, ANSI, NASA Ames, NASA HQ and CMAA requirements.

- Crane accidents and lessons learned.

- Development of a lift plan.

- Administrative locking.

- Classroom training to include the following for Critical Lift training:

- Specific hazards and special procedures associated with critical lifting.

- Demonstration of proficiency for overhead crane operation.

- Development of a hazard analysis.

- Physical examination (criteria to be determined by the cognizant medical official consistent with NPR1800.1 and based upon the related requirements associated with performing rigging tasks).

- Written examination with a seventy (70) percent score or better to pass.

- Practical examination for each individual demonstrating the ability to adequately determine and/or apply: load weight, center of gravity, special lifting devices essential to the safe and successful lift operation, proper rigging principals, methods, and techniques using simulated loads of various weights, sizes, and configurations.

- Conducted under the supervision of senior personnel within their own organization. Trainee is allowed to perform crane operator duties only in the presence of senior personnel that currently hold qualified status.

- Verified through the supervisor (using the QH form for overhead crane operator qualified status) after the trainee has achieved proficiency.

- Training cards will indicate specific crane types for which the holder is qualified to operate.

- Training will be due at least every two (2) years.

17.2.4 Aerial Lift Platforms (Manlifts)

- To become a licensed aerial lift operator the following shall be addressed:

- Classroom training to include the following for training:

- Principles of aerial lift safety and operations.

- Lifting equipment emergency procedures.

- General performance standards and requirements.

- Pre-operational checks.

- Safety-related defects and symptoms (for initial certification and as needed).

- Inspections.

- Equipment deficiencies.

- Learn about OSHA, ANSI, NASA Ames and NASA HQ requirements.

- Aerial lift accidents and lessons learned.

- Administrative locking.

- Fall protection.

- Types and parts of lift equipment.

- Operator safety rules.

- Physical examination (criteria to be determined by the cognizant medical official consistent with NPR1800.1 and based upon the related requirements associated with performing aerial lift tasks).

- Written examination with a seventy (70) percent score or better to pass.

- Practical examination for each individual demonstrating the ability to safely operate an aerial lift.

- Conducted under the supervision of senior personnel within their own organization. Trainee is allowed to perform operator duties only in the presence of senior personnel that currently holds an Ames operator's license.

- Training cards will indicate specific aerial lift types for which the holder is qualified to operate.

- Training will be due at least every two (2) years.

17.2.5 Powered Industrial Trucks (Forklifts)

- To become a licensed forklift operator the following shall be addressed:

- Classroom training to include the following for training:

- Principles of forklift safety and operations.

- Forklift equipment emergency procedures.

- General performance standards and requirements.

- Pre-operational checks.

- Safety-related defects and symptoms (for initial certification and as needed).

- Inspections.

- Equipment deficiencies.

- Learn about OSHA, NASA Ames and NASA HQ requirements.

- Forklift accidents and lessons learned.

- Administrative locking.

- Types and parts of forklift equipment.

- Operator safety rules.

- Instruction for the type of industrial truck the holder is qualified to operate.

- Physical examination for medical clearance (criteria to be determined by the cognizant medical official consistent with NPR1800.1 and based upon the related requirements associated with performing forklift operation).

- Written examination with a seventy (70) percent score or better to pass.

- Practical examination for each individual demonstrating the ability to safely operate a forklift.

- Conducted under the supervision of senior personnel within their own organization. Trainee is allowed to perform operator duties only in the presence of senior personnel that currently holds an Ames operator's license

- Include the following for Critical training:

- Specific hazards and special procedures associated with critical operations.

- Demonstration of proficiency and operating finesse.

- Training cards will indicate specific forklift types and size for which the holder is qualified to operate.

- Training will be due at least every two (2) years.

17.2.6 Revocation of Operator License/Certification

- A representative from the Health, Safety & Medical Services Division may revoke a license or certification card by collecting the card in person or contacting the card holder in writing for acts of negligence, violations of safety requirements or failure to meet medical standards. The supervisor is to be notified of the revocation in writing.

17.2.7 Lessons Learned

- The Lifting Device Equipment Manager shall:

- Disseminate Crane mishap and close call lessons learned information to the Lifting Device Equipment Committee.

- Disseminate Crane mishap and close call lessons learned information to the Safety, Health and Medical Services Division Training Program Manager for inclusion in the training course curriculum.

- Disseminate Crane mishap and close call lessons learned information to the Ames Lessons Learned Administrator for inclusion in the NASA HQ Lessons Learned system.

[Back to Table of Contents]

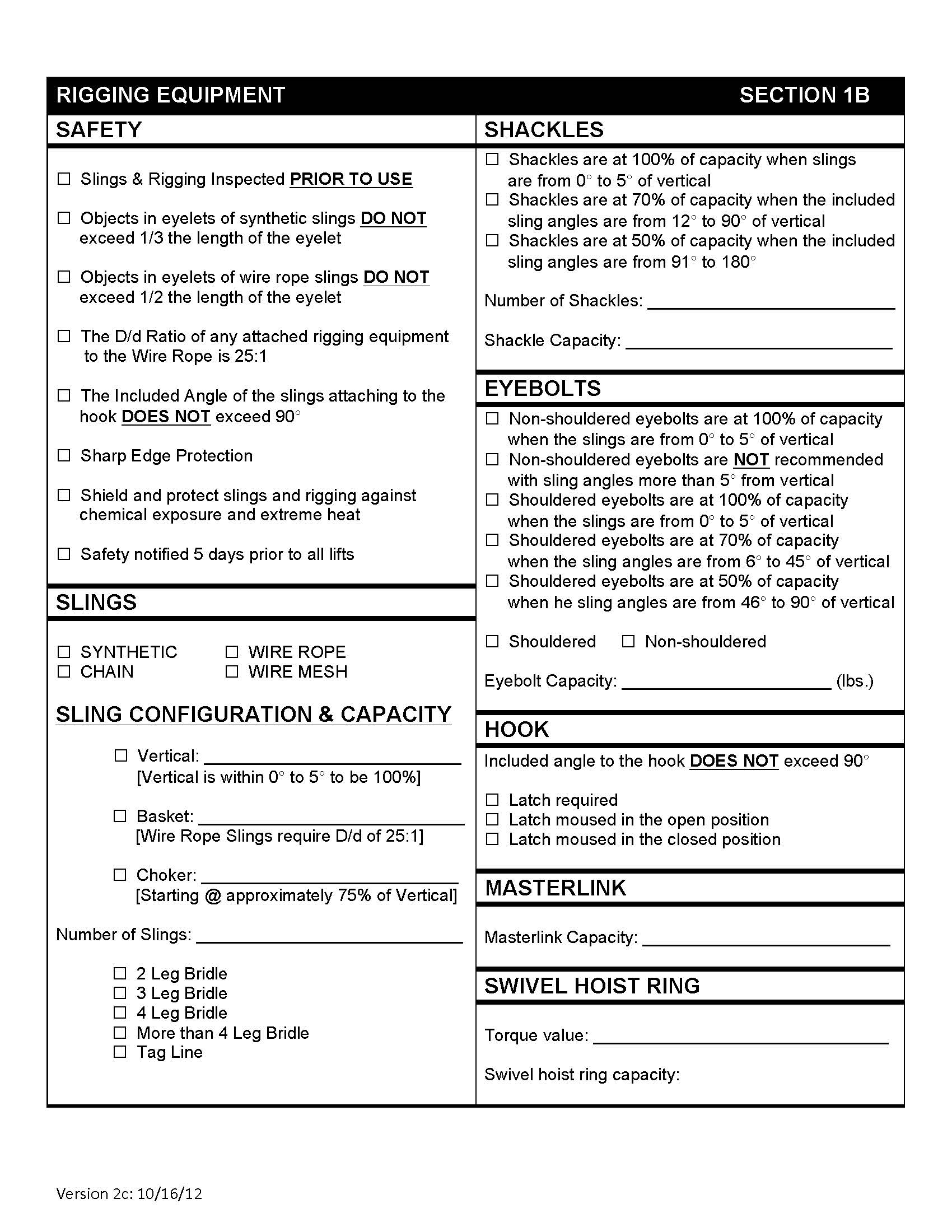

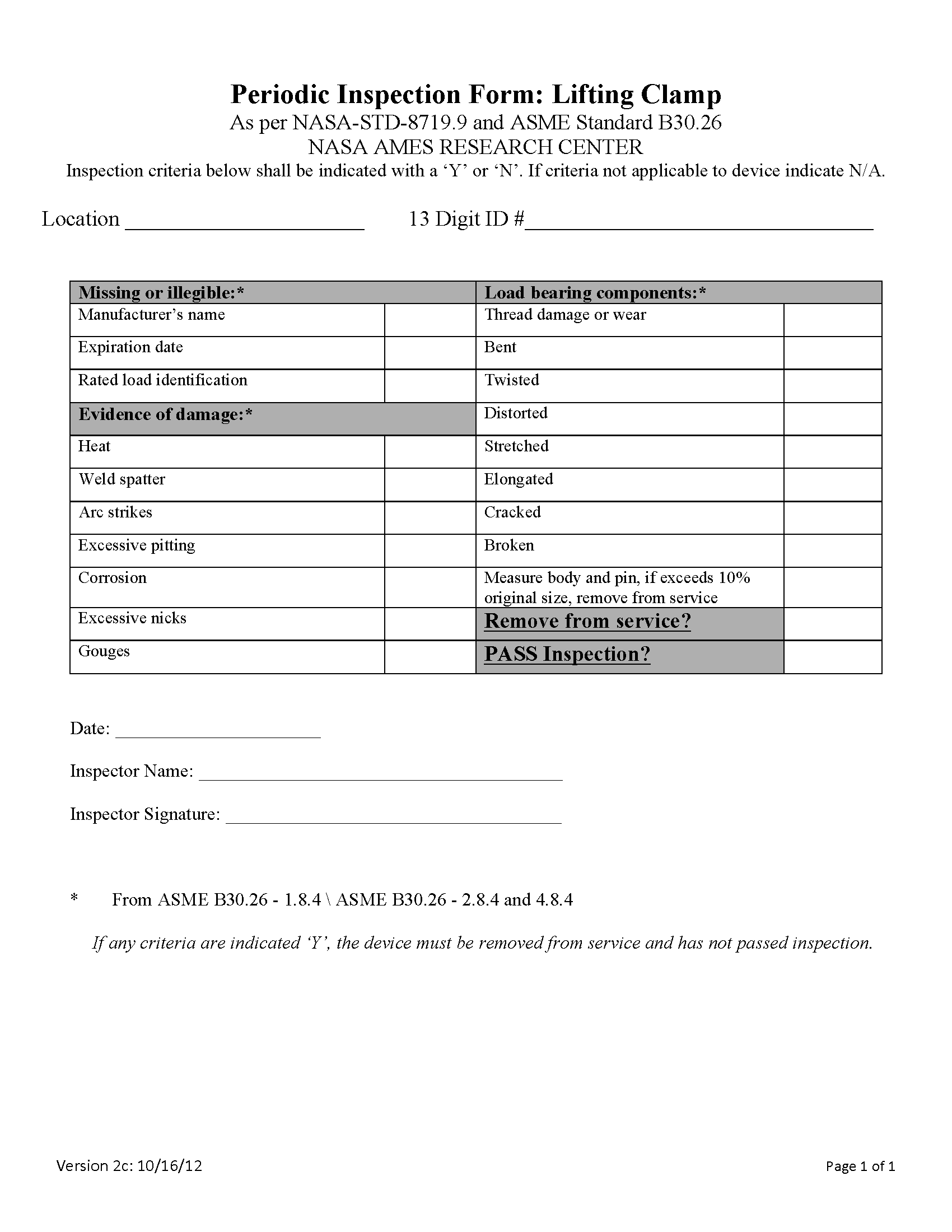

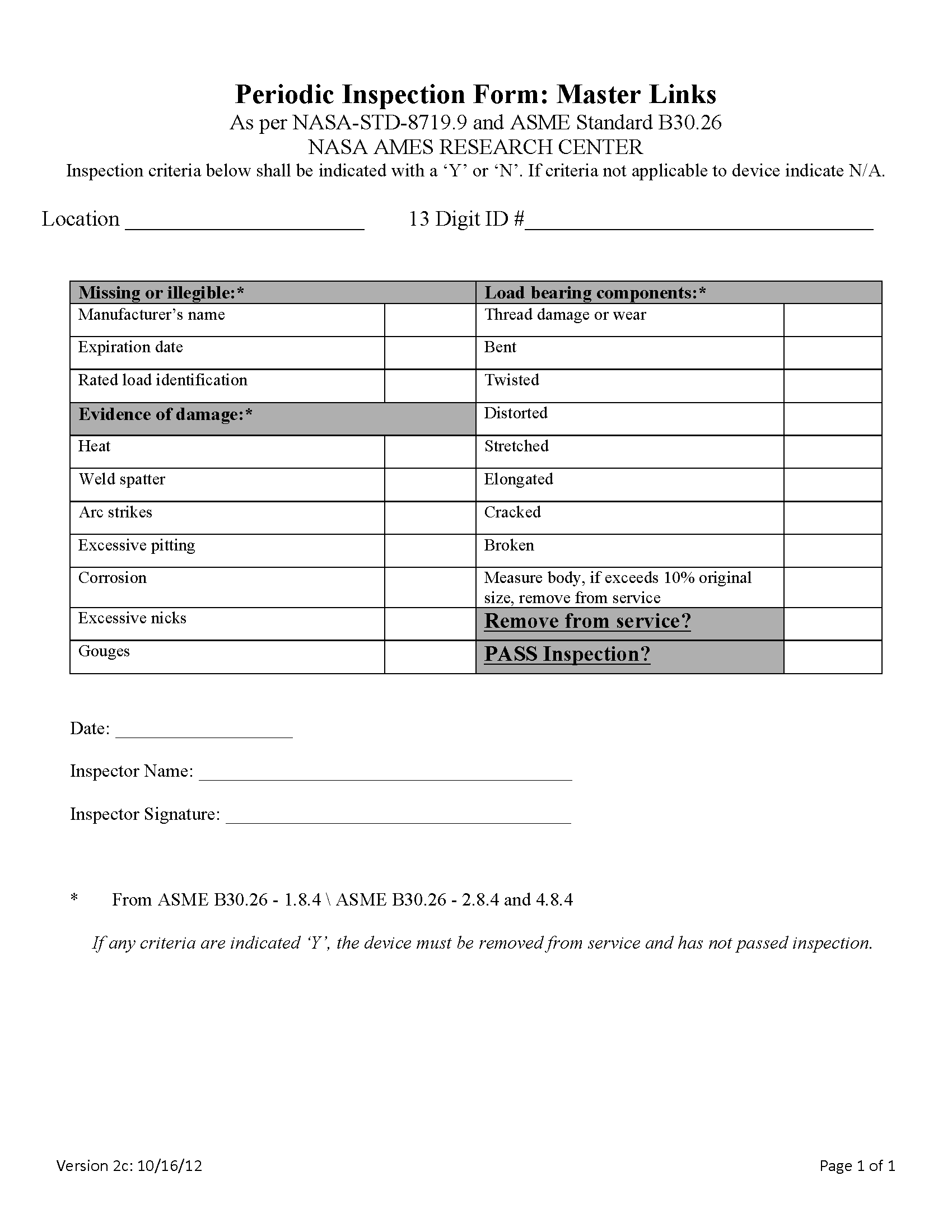

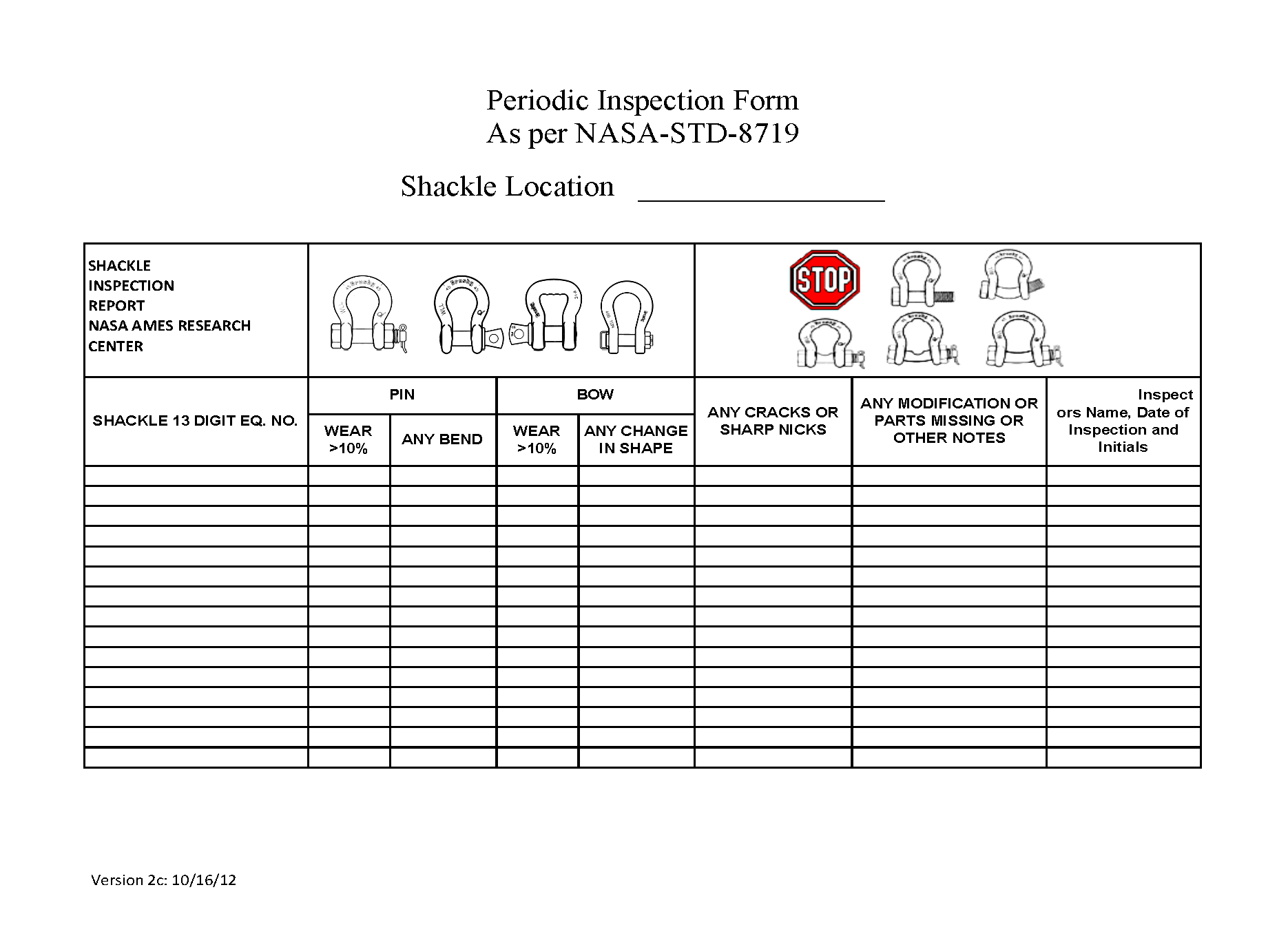

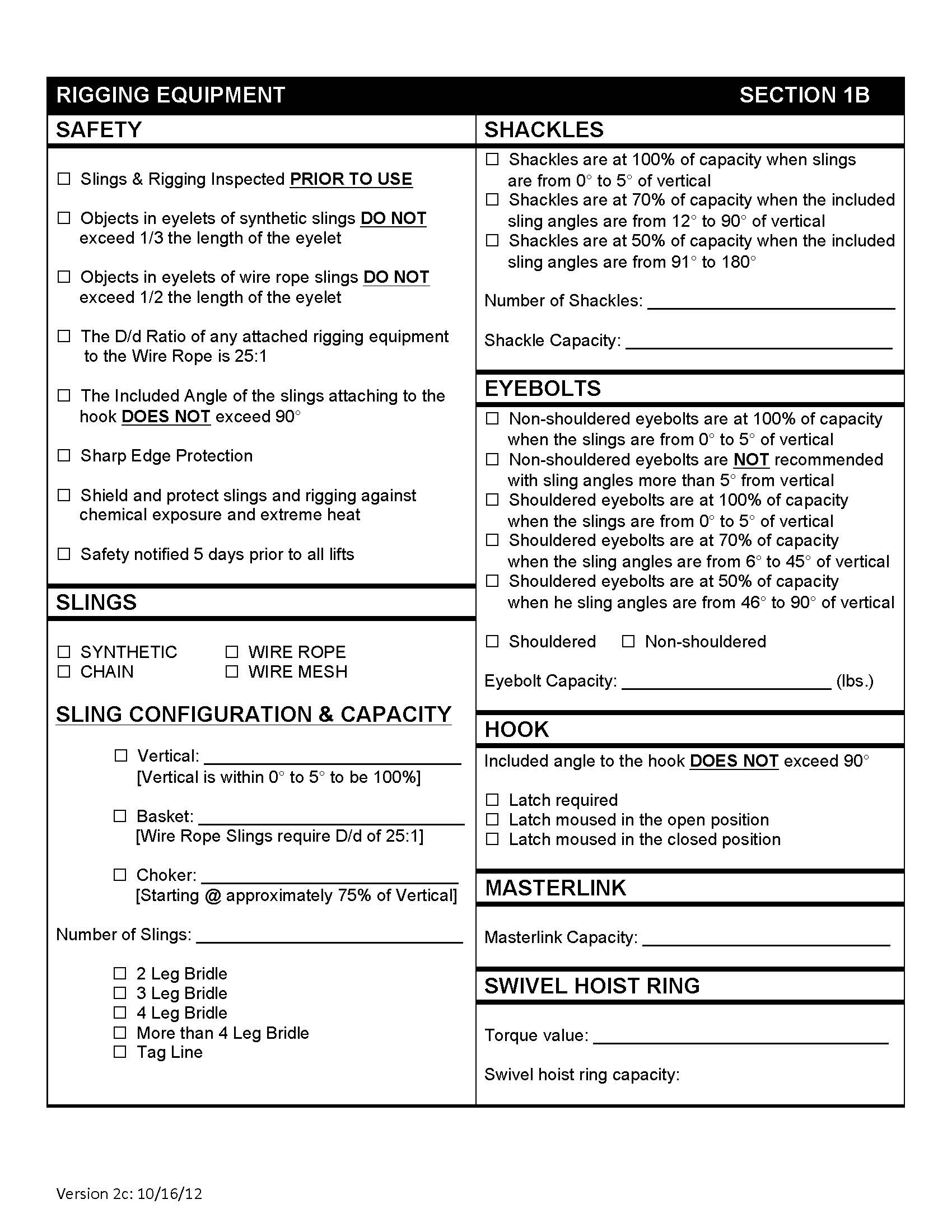

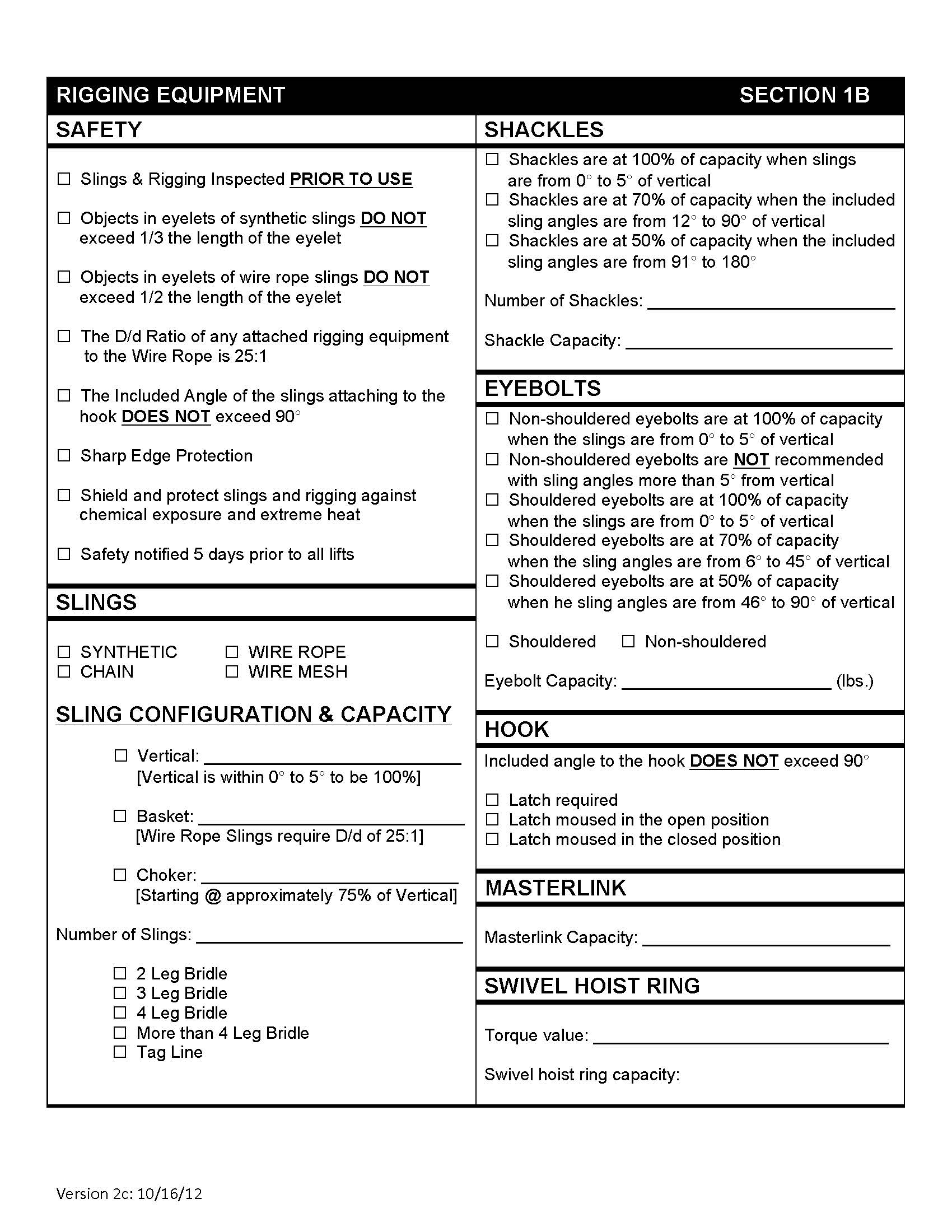

17.3 Rigging Hardware

- This entire section includes any lifting hardware used below the crane hook for critical and non-critical use.

17.3.1 General requirements:

- Each organization that owns lifting devices shall:

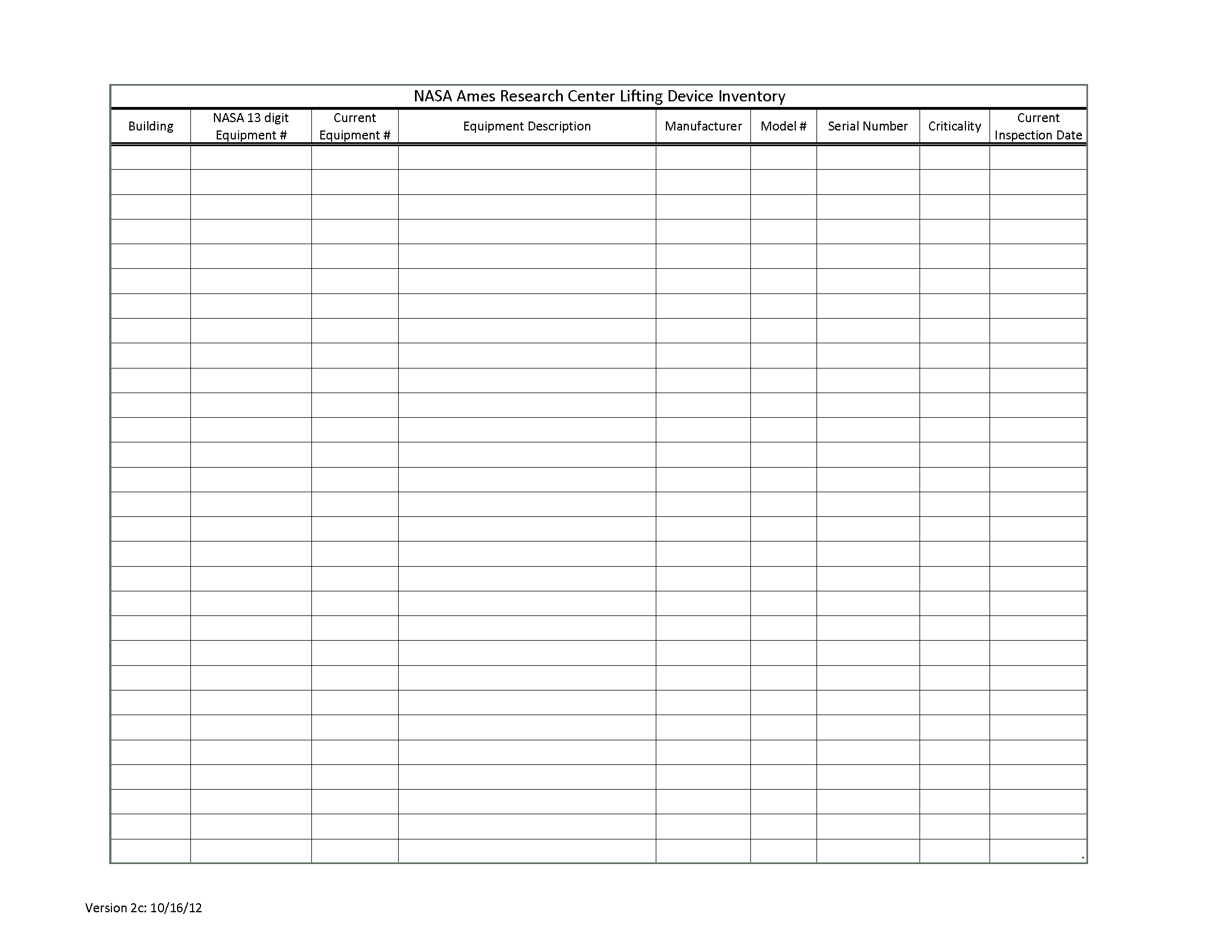

- Compile an inventory of equipment they control and deliver completed inventory to the LDEM or alternate. See appendix for Inventory form.

- Update inventory when new equipment is purchased and deliver completed inventory to the LDEM or alternate. See appendix for Inventory form.

- Ensure rigging hardware is periodic load tested by a certified company who is qualified to perform the required testing.

- Ensure that non destructive testing of rigging hardware is conducted (and documented) when sending hardware out for its required periodic load test.

- Ensure that manufacturer's original markings are legible on the rigging hardware to include the name or trademark of the manufacturer, grade, material type, working load limit (WLL) and size.

- Ensure equipment is stored so that damage by heat, moisture, sunlight or chemicals does not occur.

- Ensure that all currently certified rigging hardware is secured in a manner to prevent use by anyone who is not designated as a qualified rigger to use the equipment. Acceptable methods include areas that can be locked and are not shared for any other purpose such as lockers, cages, closets, drawers and rooms.

- Ensure that all non certified rigging hardware is secured in a manner to prevent use by anyone.

- Ensure that critical and non-critical rigging hardware is physically separated within the secured area but in a manner so they will remain separated.

- Ensure that damaged rigging hardware is destroyed in a manner to prevent use before discarding.

- Ensure that rigging hardware meets the requirements under OSHA, ASME B30 and NASA-STD-8719.9 (Standard for Lifting Devices and Equipment).

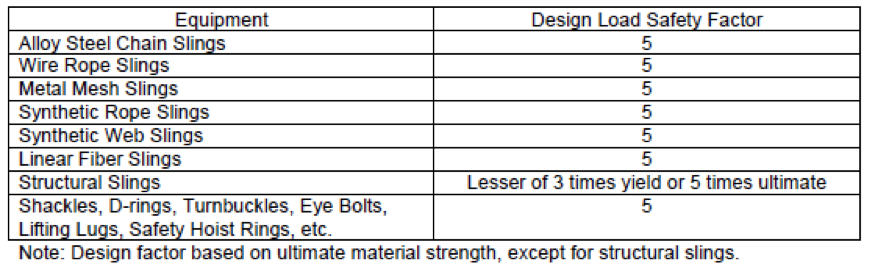

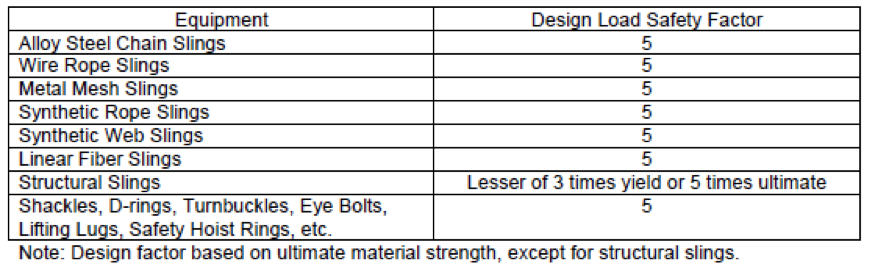

- Ensure that rigging hardware design meets and maintains the minimum design factors listed in Table 1.

- Ensure that Personal Protective Equipment (PPE) is available and worn to include: gloves, hard hats, safety glasses, safety shoes or other PPE as indicated in the approved lift plan.

- Hardhats are required for all personnel during mobile crane lifts.

- Hardhats are required for all personnel during overhead crane lifts where the load is to be lifted above shoulder height.

- Contact the LDEM and receive specification approval prior to procurement of rigging hardware.

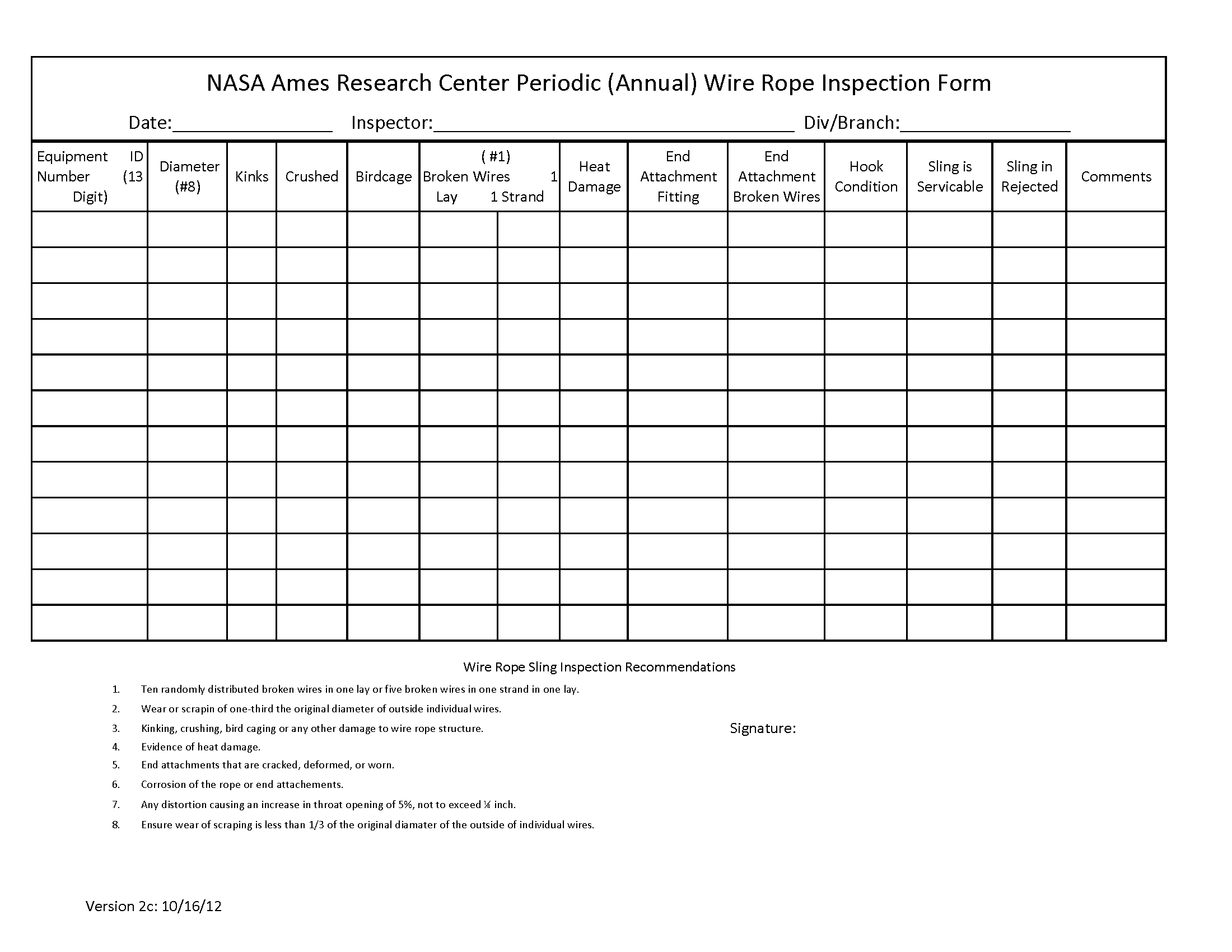

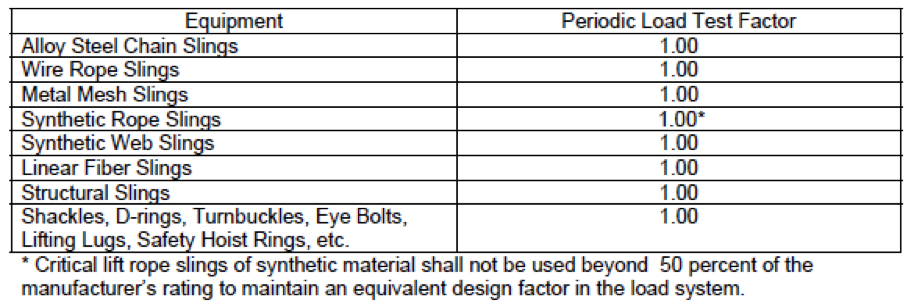

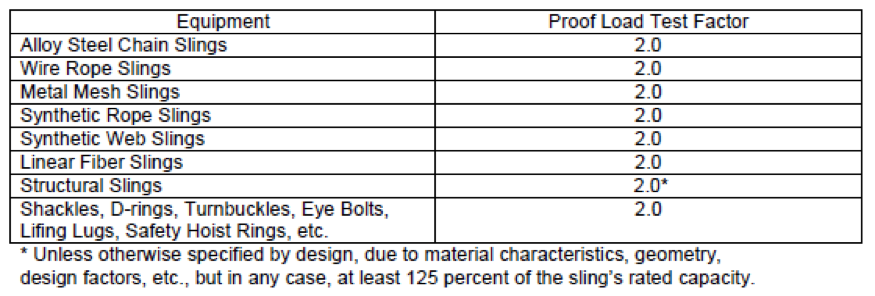

Table 1: Minimum Design Factors for Rigging Hardware

17.3.2 Critical Lift Tagging and Testing

- Rigging hardware requirements for critical lifts:

- Periodic load testing and re-certification is required annually.

- Periodic load test reports are submitted to the LDEM or alternate and the supervisor.

- Following a periodic load test, all rigging hardware shall meet the following:

- Have a permanently affixed red colored tag identifying the Maximo database thirteen digit tracking number that has been issued through the LDEM.

- Have the WLL listed on the tag. For Synthetic rope slings, list the WLL at fifty (50) percent of the manufacturer's rated load and the type of material.

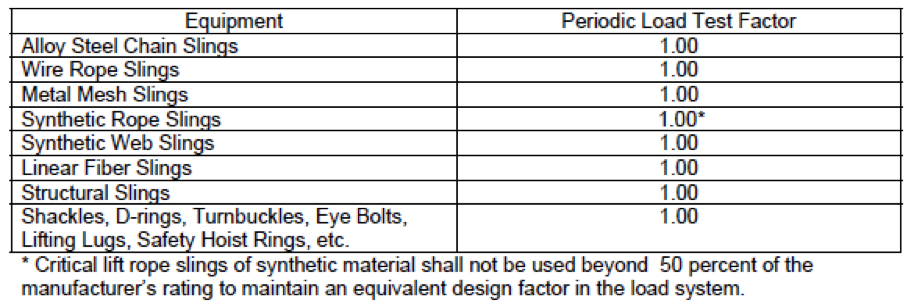

- Have the next periodic load test expiration date listed on the tag. See Table 3 for Periodic Load Test Factors.

- For alloy steel chains also list size, grade and reach or length on the tag.

- Proof load testing is required before use, for new hardware, when extensively repaired or modified at two-hundred (200) percent of rated load. Proof load tests performed by the manufacturer prior to delivery are acceptable, if the necessary load test papers are provided to verify the extent and thoroughness of the test on the specific item.

- Operational testing is required prior to use on an annual basis.

17.3.3 Non-Critical Lift Tagging and Testing

- Testing and Periodic Recertification Tags:

- Testing and recertification is required every four (4) years.

- Reports are kept on file for a minimum of two test cycles with the Lifting Device Equipment Manager (LDEM).

- Following a load test, all rigging hardware shall meet the following:

- Have a permanently affixed tag identifying the Maximo database thirteen digit tracking number that has been issued through the LDEM .

- Have the WLL listed on the tag.

- Have the next periodic load test expiration date listed on the tag. See Table 3 for Periodic Load Test Factors.

- Proof load testing is required before use, for new hardware, when extensively repaired or modified at two-hundred (200) percent of rated load. Proof load tests performed by the manufacturer prior to delivery are acceptable, if the necessary load test papers are provided to verify the extent and thoroughness of the test on the specific item.

- Operational testing is required prior to use on an annual basis.

Table 3: Periodic Load Test Factors

17.3.4 Maintenance & Inspection Program

- A program based on manufacturers' recommendations integrating proactive, reactive, preventative and predictive maintenance is required at NASA Ames. The goal of our program is to increase the probability that all rigging hardware and equipment will function in the required manner over its design life cycle with a minimum of maintenance.

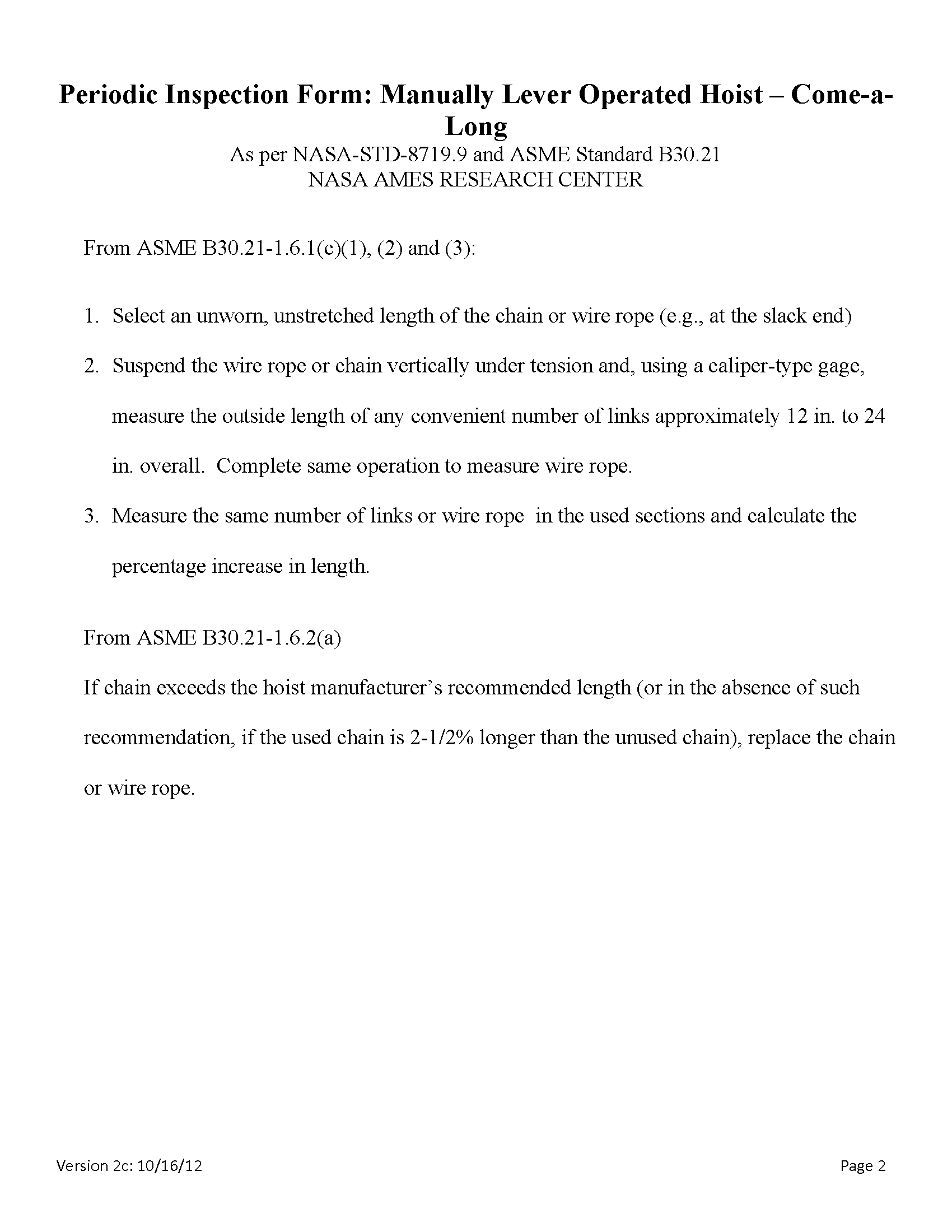

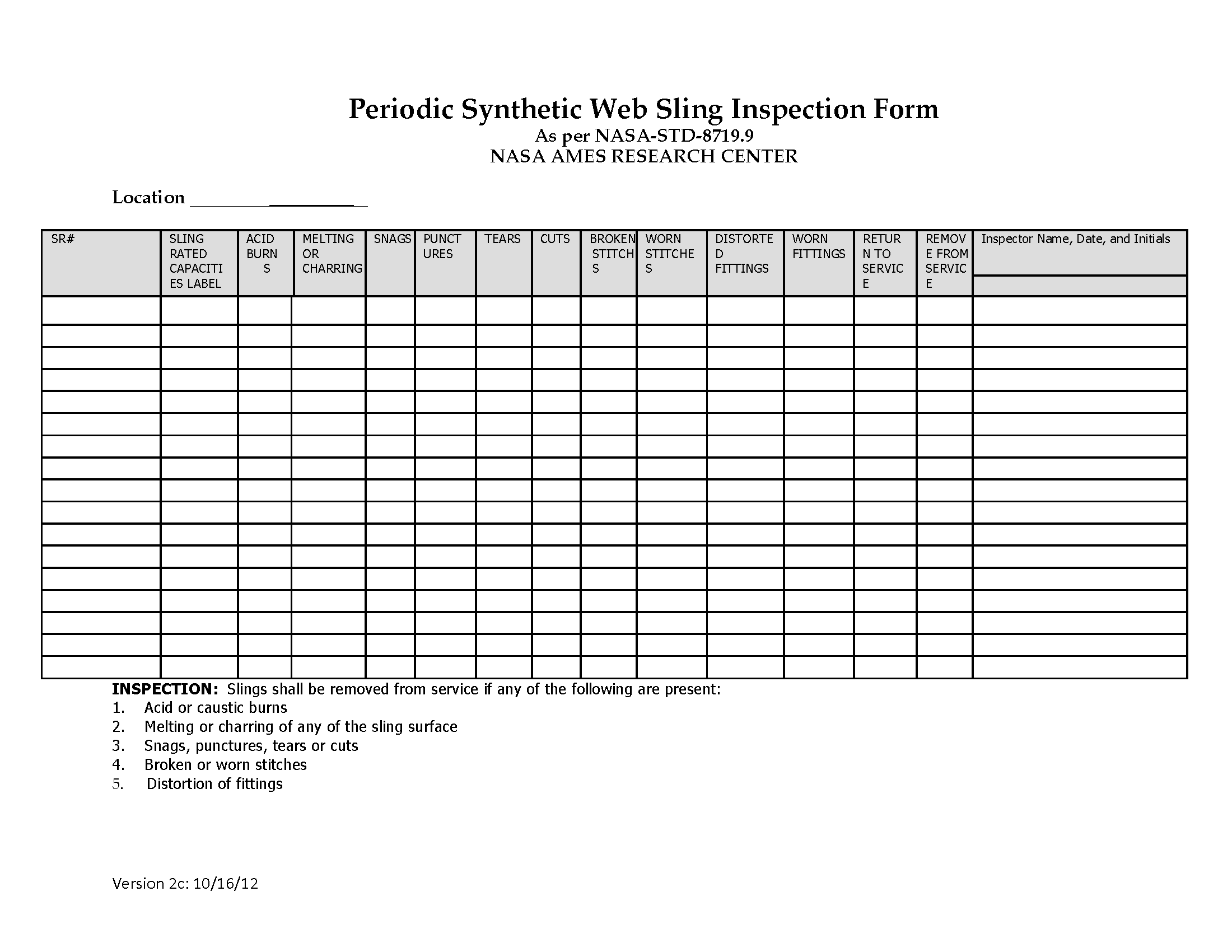

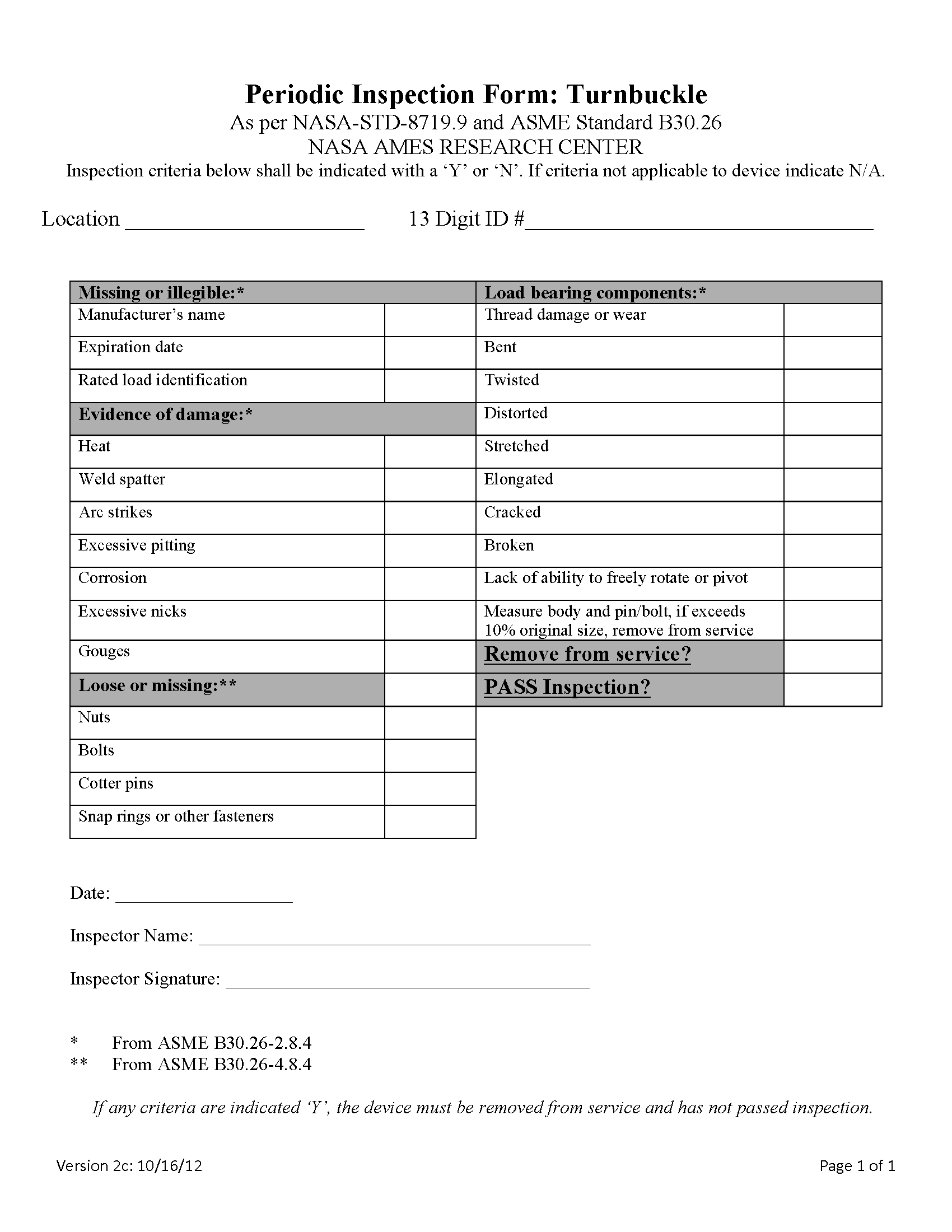

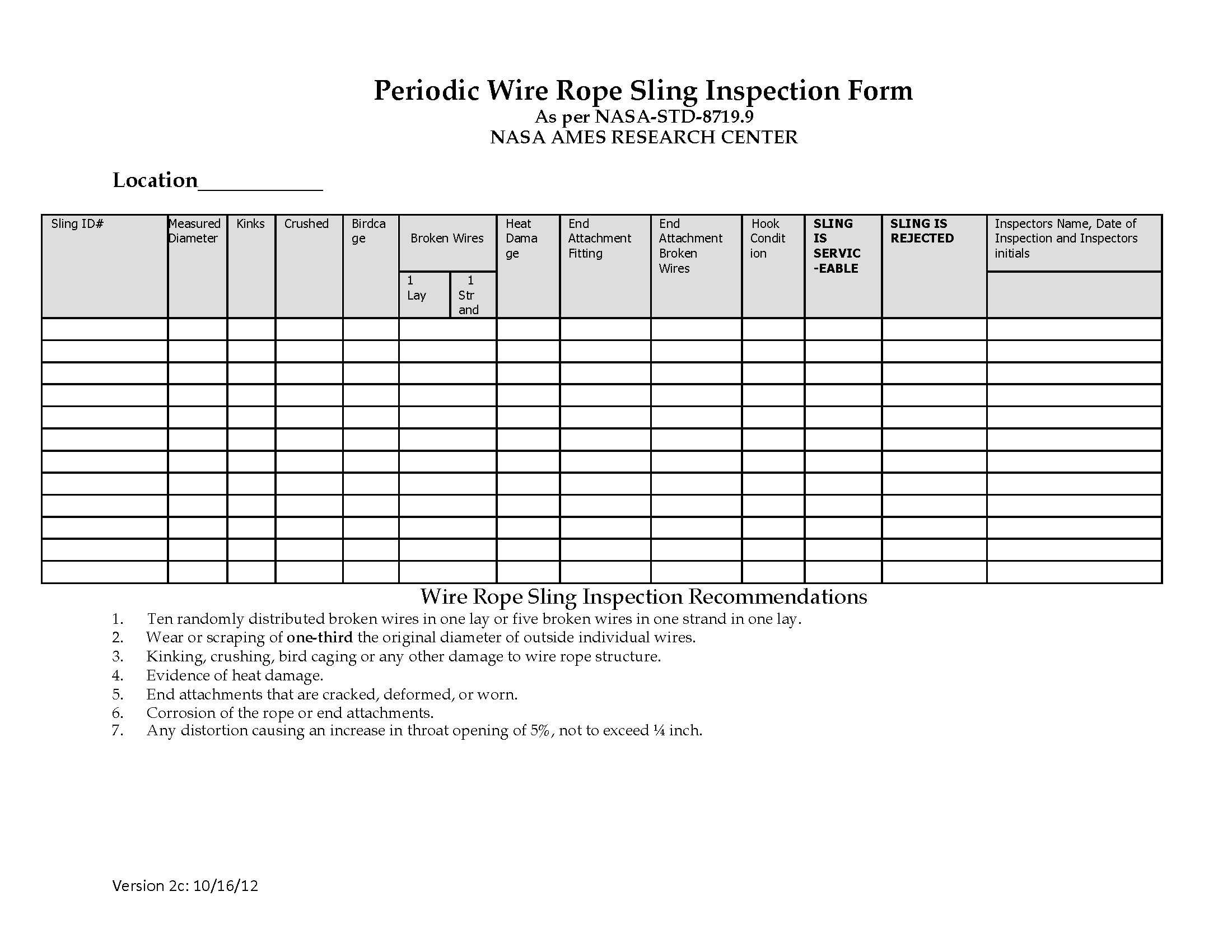

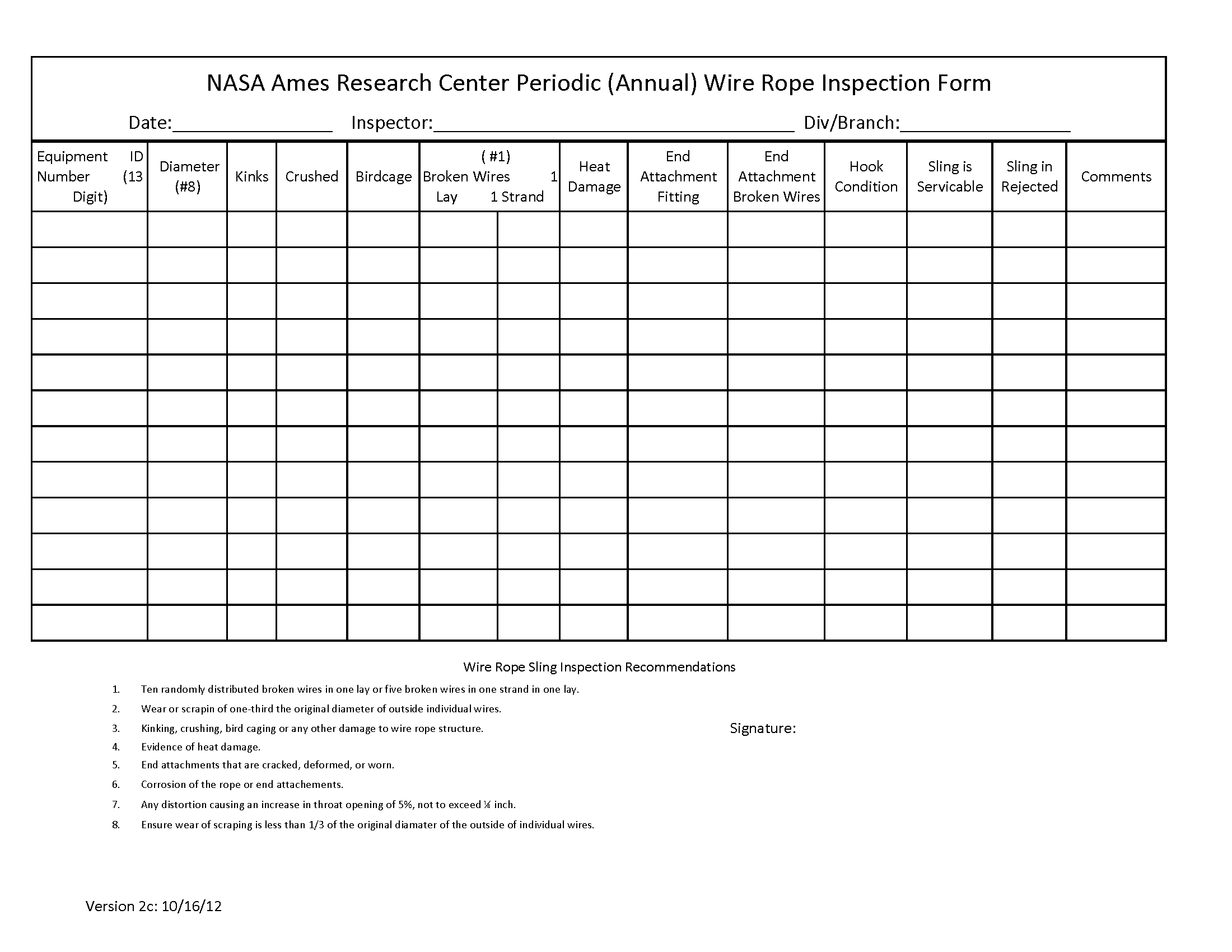

- Documented inspections for all hardware in regular service (used at least once a month) are required by NASA-STD-8719.9 (Standard for Lifting Devices and Equipment) and include:

- Daily - Prior to first use each day the sling is used.

- Check for defects such as cracks, deformations, gouges, galling, kinks, crushed areas and corrosion.

- Check for proper configuration (lifting assembly and associated hardware, as proof load tested).

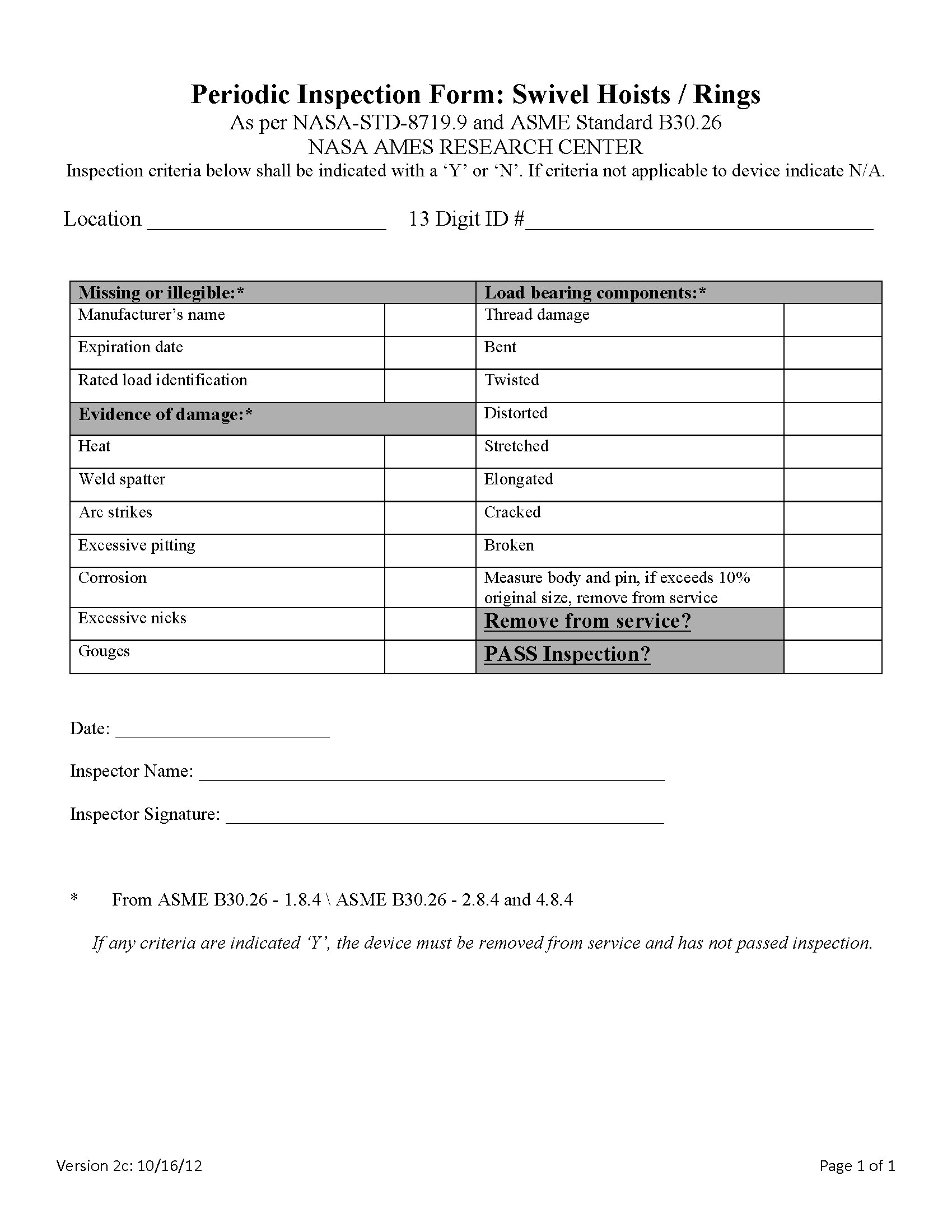

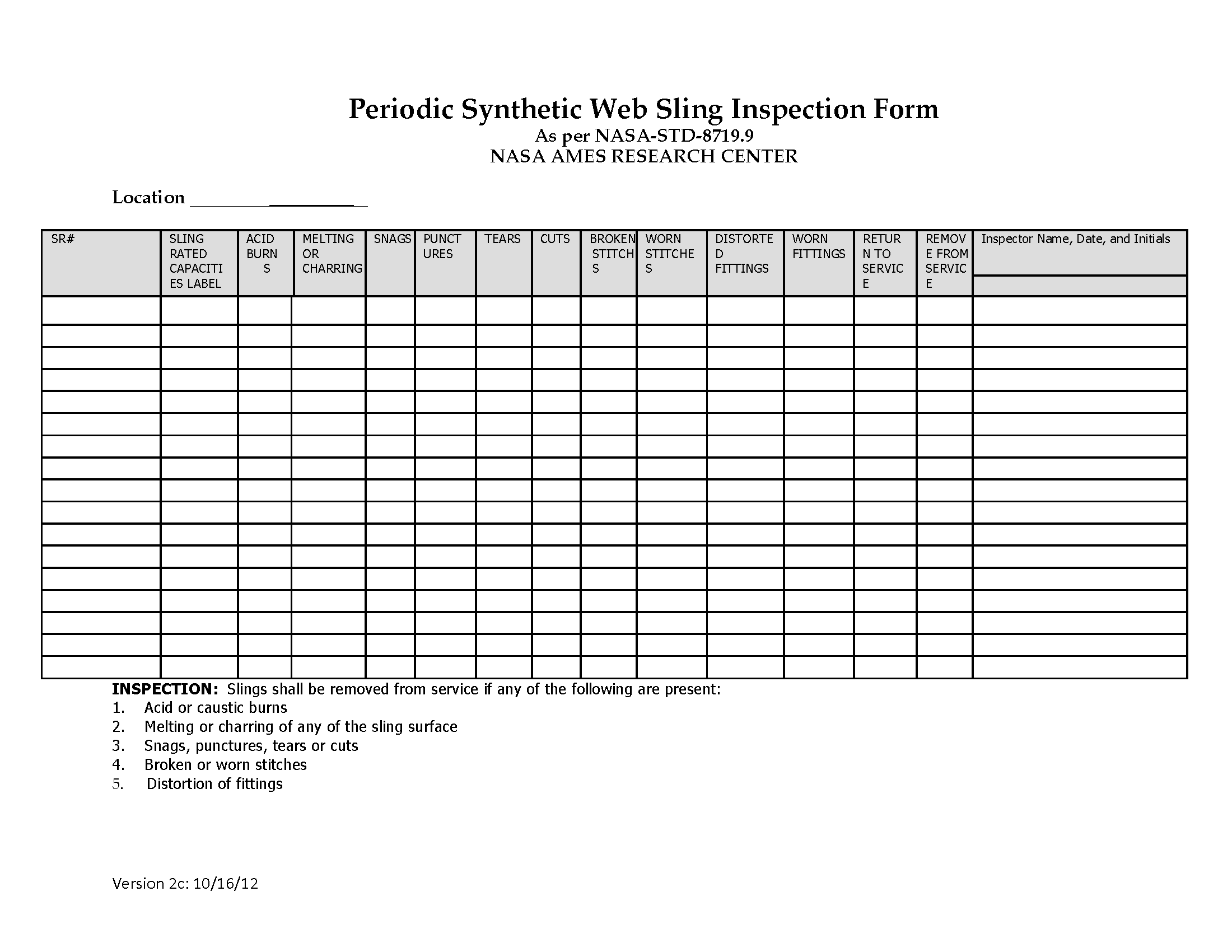

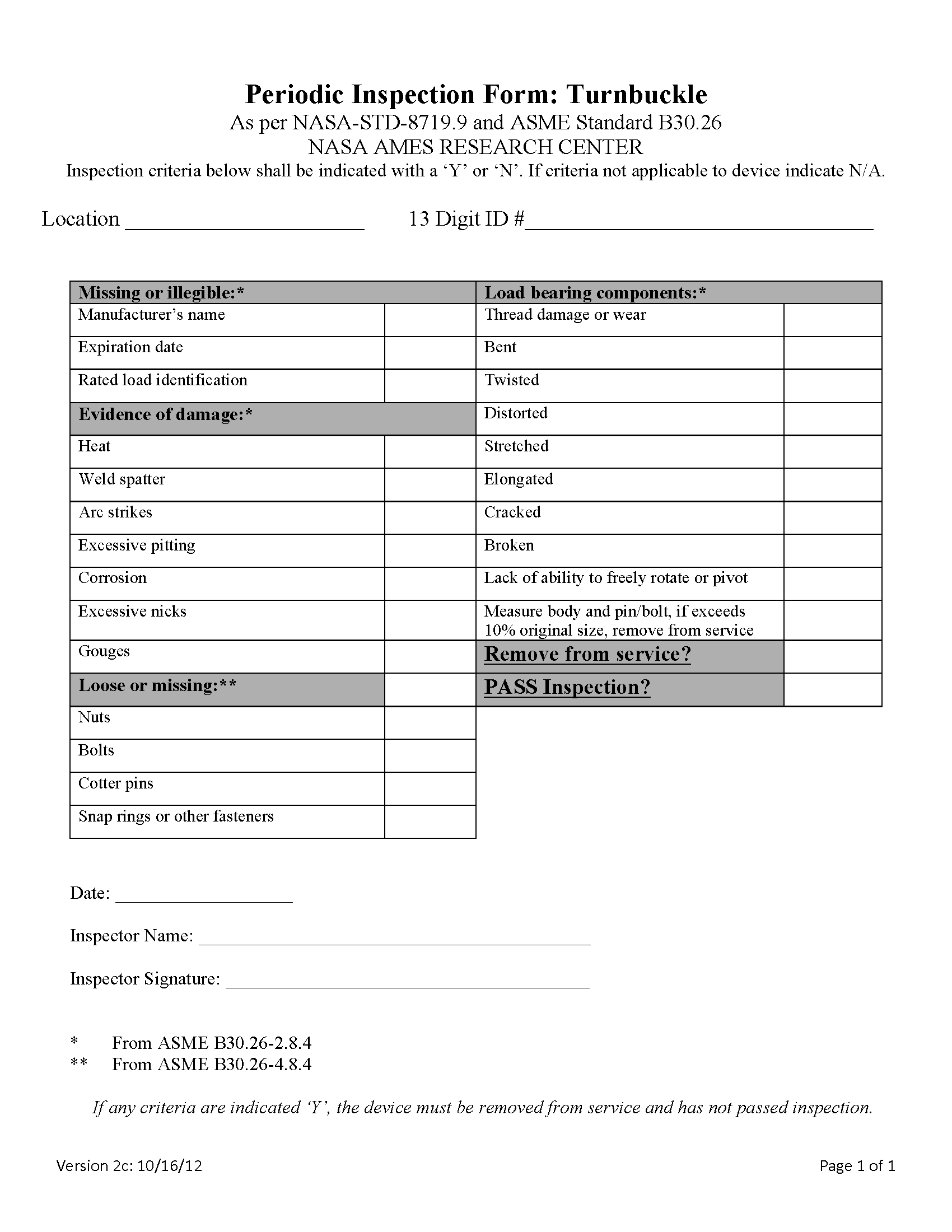

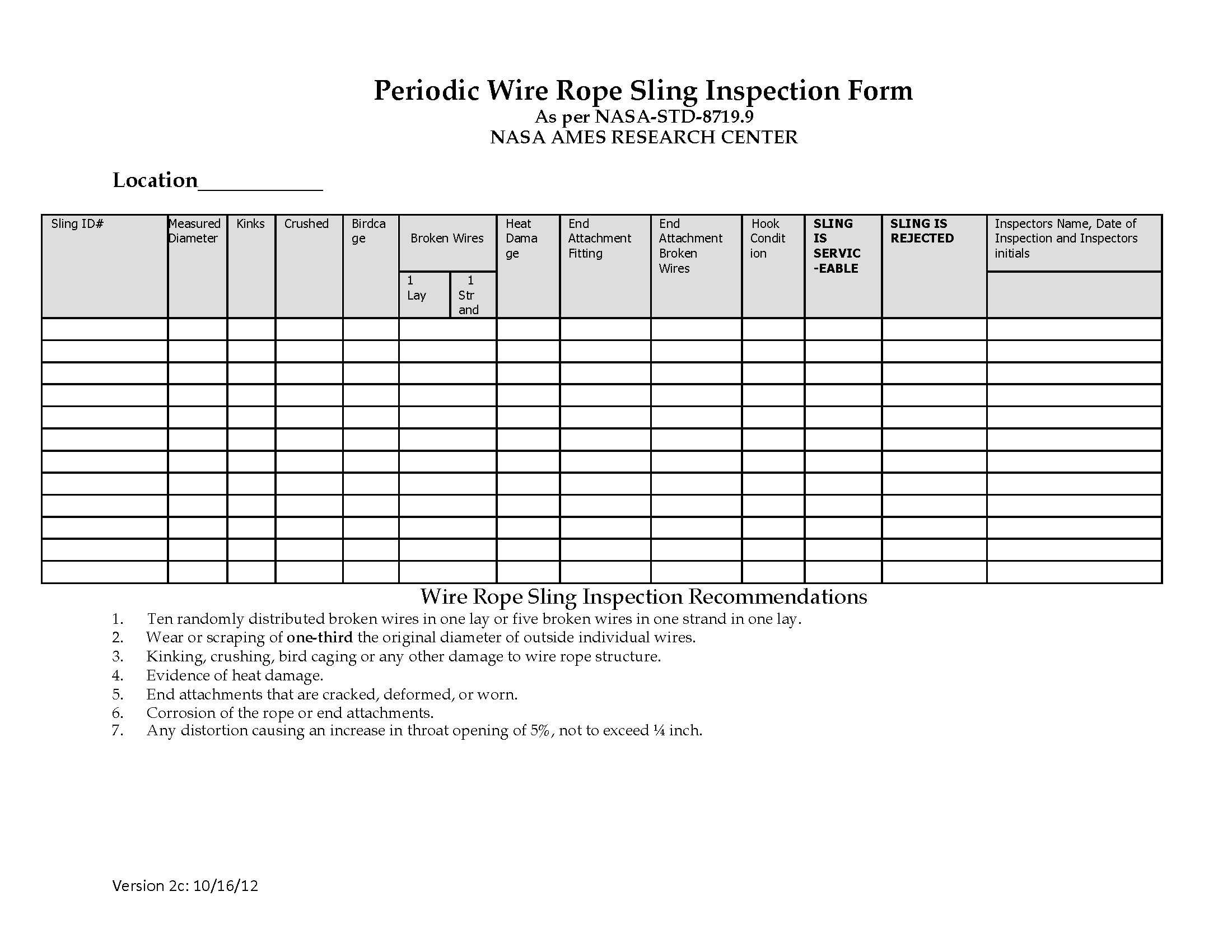

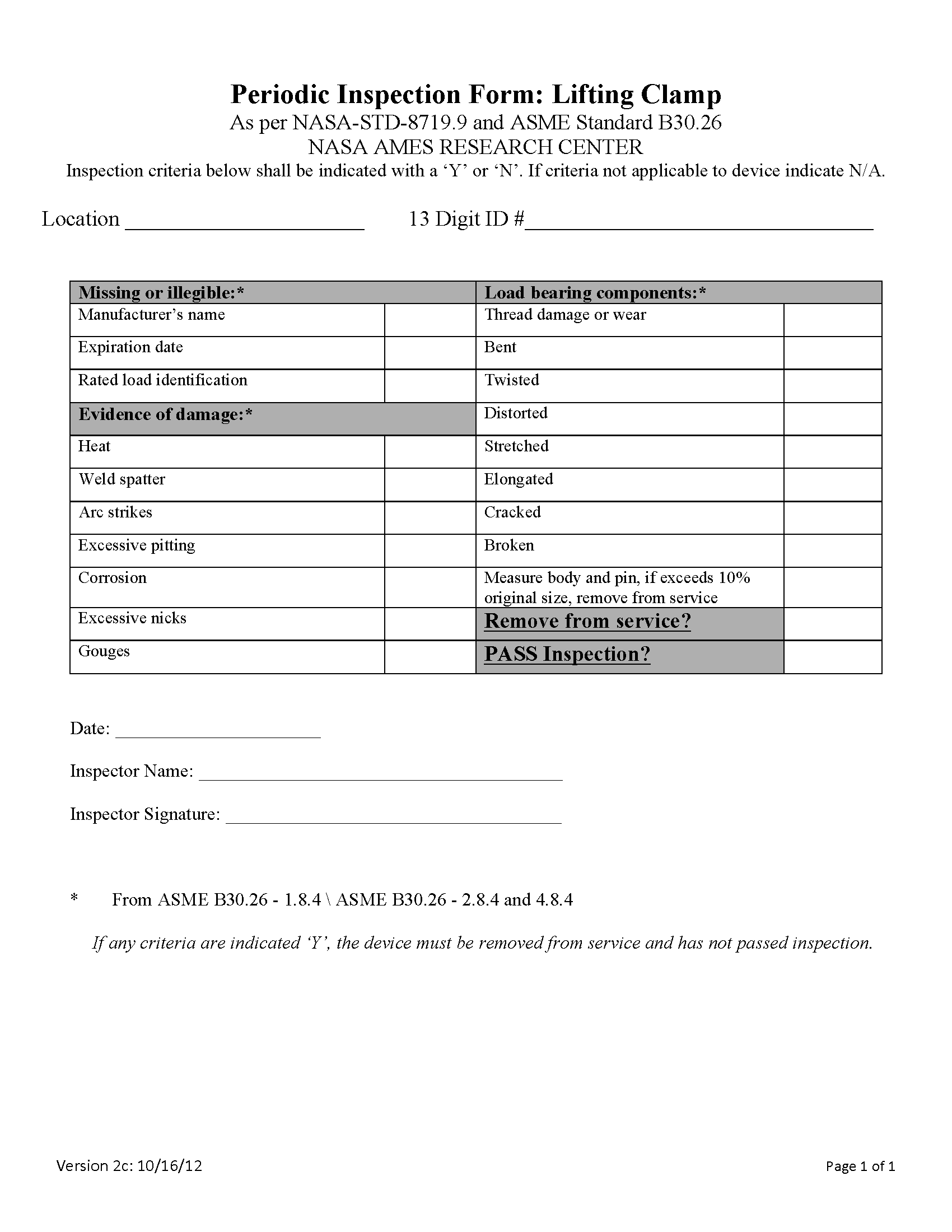

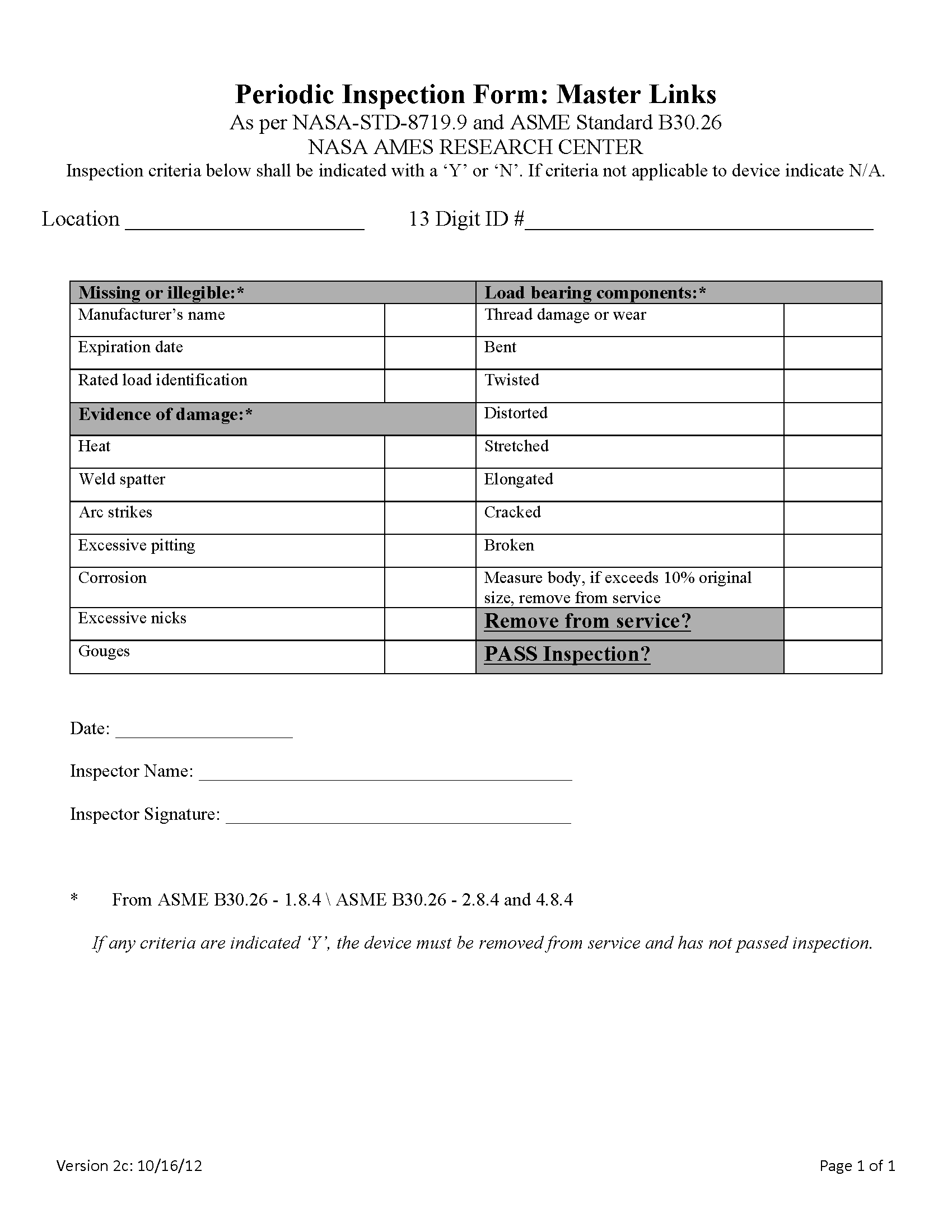

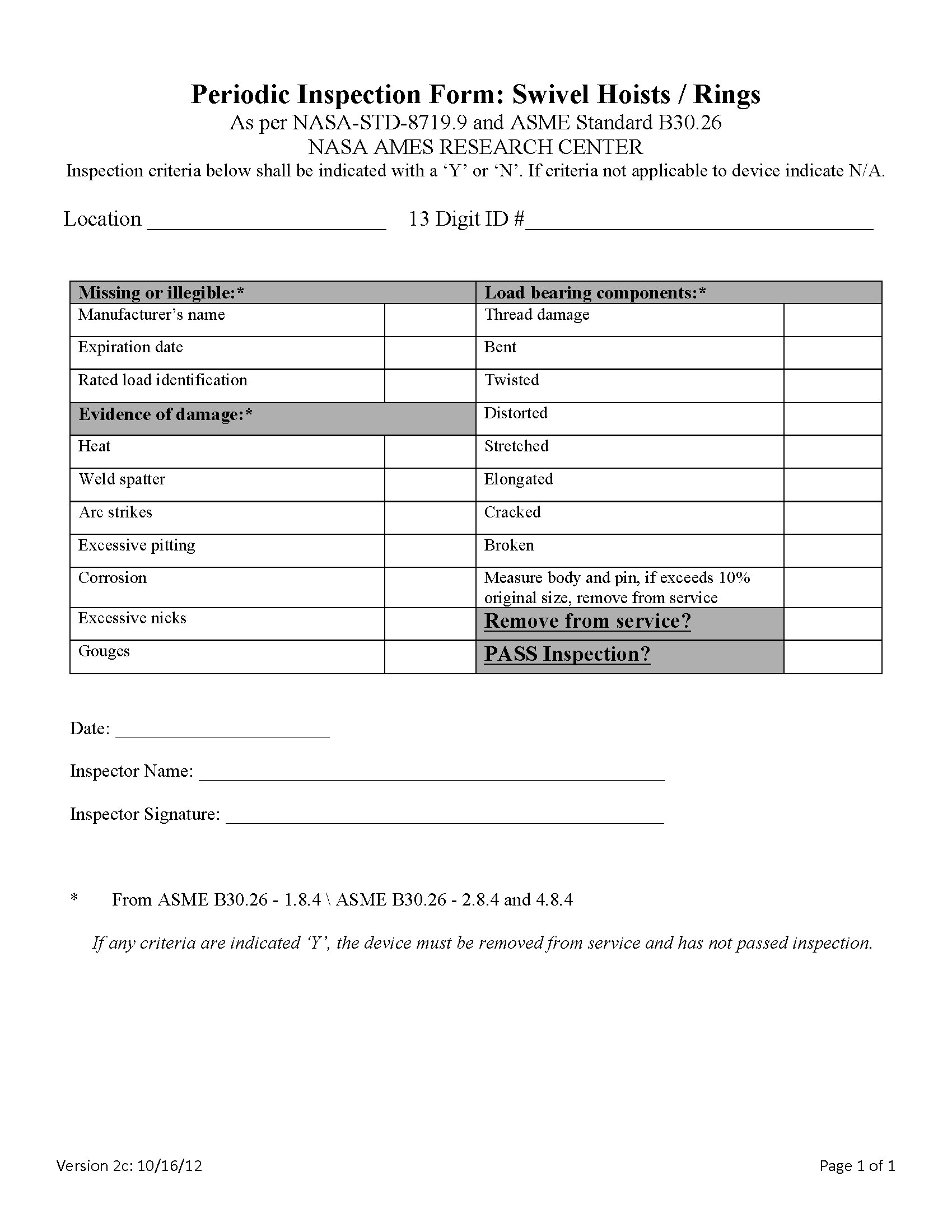

- For inspection forms, see Appendix.

- Periodic Inspections - At least once a year. The need to replace or repair all rigging hardware is determined by a certified or otherwise qualified person based on an evaluation of inspection results.

- For inspection criteria, see NASA-STD-8719.9 (Standard for Lifting Devices and Equipment) section 10.4.5 (Periodic Inspections).

- For inspection forms, see Appendix.

- Complete inspection forms on an annual basis before their expiration date and submit to the LDEM. The Maximo system will generate the reminder a minimum of thirty (30) days before the inspection is due.

- The Lifting Device Manager (LDEM) is responsible for oversight of the program and recordkeeping which shall include:

- Monthly documented audit.

- LDEM is to generate monthly report through Maximo of all cranes, rigging hardware for critical and non-critical that was due for the previous month then separate by directorate and give to Alternate LDEM(s).

- Alternate LDEM(s) are to verify completion then document and report back to the LDEM.

- A ten (10) percent random spot check with a representative from the Health, Safety and Medical Services division.

- The Maximo system is used for tracking and documentation of equipment and lifting hardware.

17.3.5 Proof Load Test

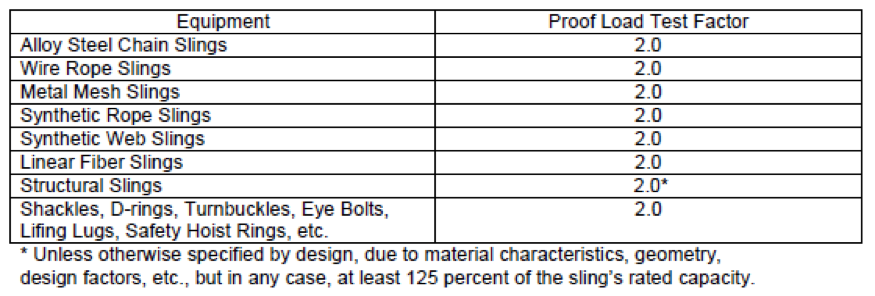

- Before first use, unless noted below, all new, extensively modified, repaired, or altered slings and rigging equipment shall undergo a proof load test at two (2) times the rated load (except for structural slings may be tested at one hundred twenty-five (125) percent of the rated capacity if specified by design, due to material characteristics, geometry, design factors, etc.) Proof load tests performed by the manufacturer prior to delivery are acceptable, if the necessary load test papers are provided to verify the extent and thoroughness of the test on the specific item. The proof load test papers are sufficient documentation until next periodic load test is scheduled. See Table 2 for Proof Load Test Factors.

- Proof load test may be substituted at the time of purchase if manufacture test papers suggest a load test of one hundred and twenty-five (125) percent of the working load limit has been completed. This documentation must be maintained by the user group.

Table 2: Proof Load Test Factors

[Back to Table of Contents]

17.4 Overhead Cranes

- Personnel working with overhead cranes shall:

- Establish and maintain safe zones (areas not to be entered by personnel during the lift unless authorized and necessary to perform assigned duties) before lifts begins and place appropriate barriers in place.

- Prevent anyone from becoming under a suspended load, become trapped, crushed or pinched.

- Know the weight of the load.

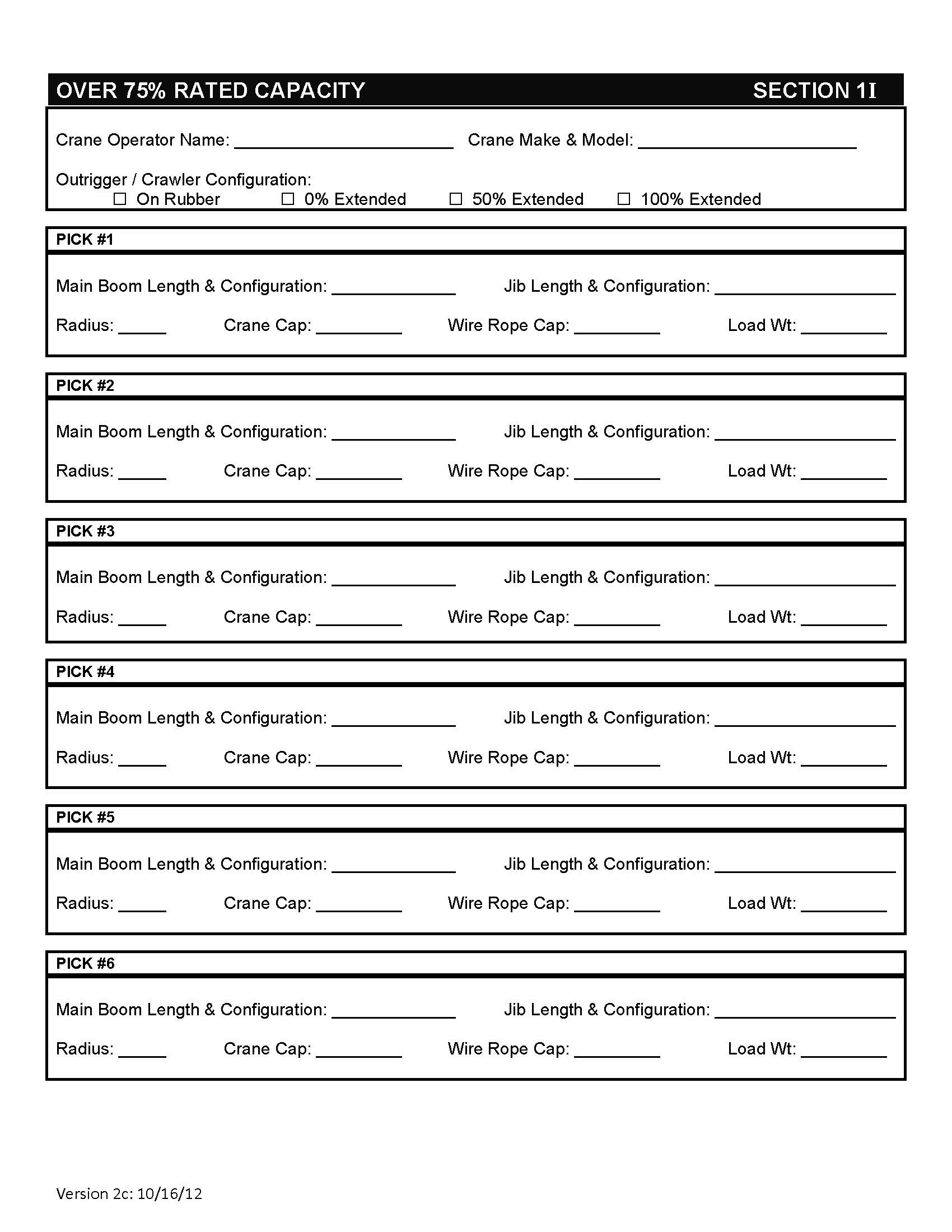

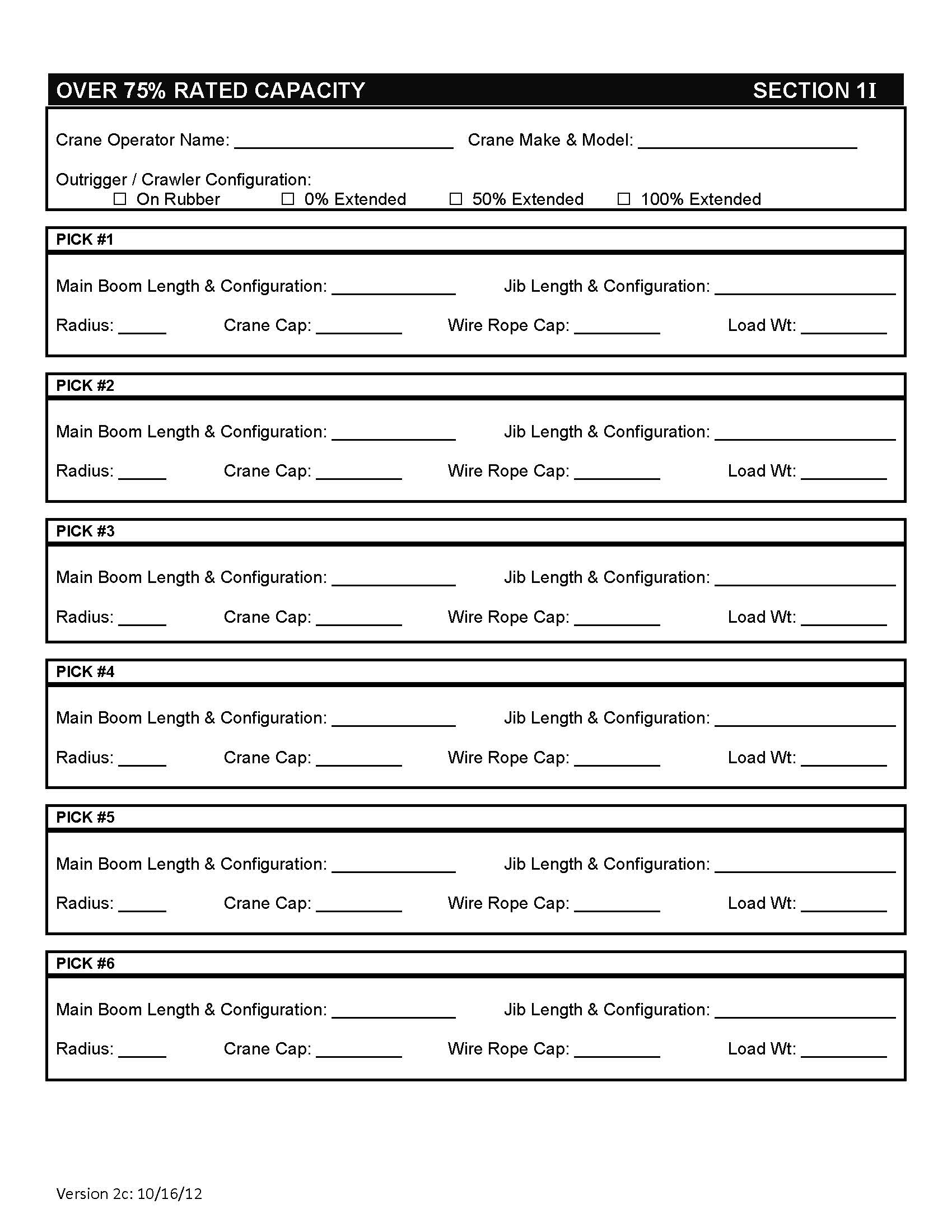

- Test holding brakes for weights above seventy-five (75) percent of rated capacity, according to NASA-STD-8719.9 (Standard for Lifting Devices and Equipment).

- Test radio communications. If communications are lost, stop all operations until restored.

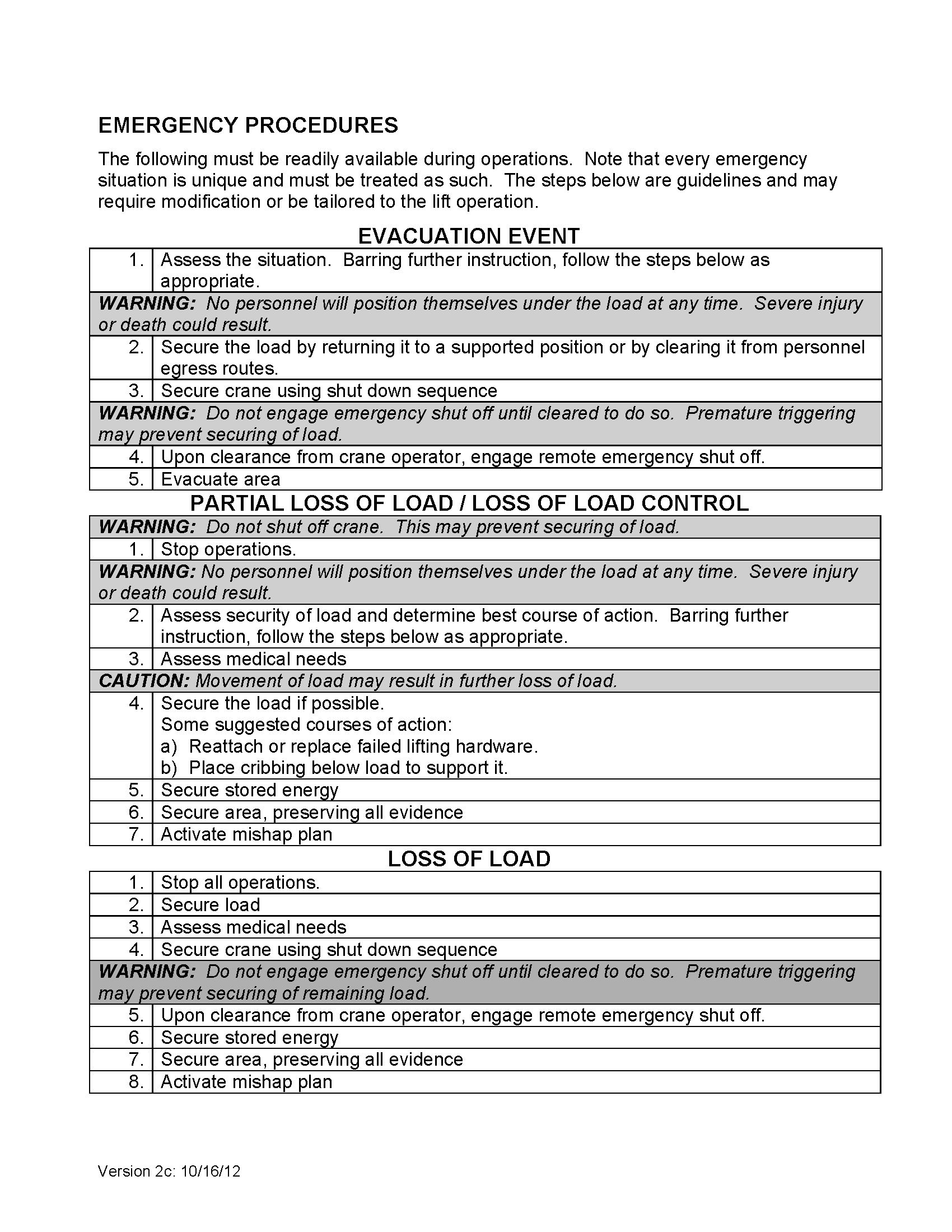

- Establish written emergency procedures which are to be communicated to everyone involved in the operation. See the Operating Procedures for Emergencies section of this chapter for additional information. (7). Meet prior to lift for a safety briefing that covers the following at a minimum:

- Review of hand signals to be used (standard or job specific).

- Lift procedure.

- Hazards and special precautions.

- Responsibilities.

- Personal protective equipment.

- Affected area.

- Emergency procedures.

- Ensure that lifting pathway is free of obstructions.

- Ensure that Personal Protective Equipment (PPE) is available and worn to include: gloves, hard hats, safety glasses, safety shoes or other PPE as indicated in the approved lift plan.

- Hardhats are required for all personnel during overhead crane lifts where the load is to be lifted above shoulder height.

- Ensure that outdoor hoisting operations do not take place if winds are above 20 knots (23 mph) steady state or gusts exceed 35 knots (40 mph). Weather will also be a consideration before lift operations occur such as rain or lightening.

- Document any deficiency found during the pre-operational check and remove from service using administrative locking until steps are taken to correct deficiency.

- Ensure that all overhead crane activities follow a written operational procedure. The operational procedure is a document that defines the scope of the project and lists step by step procedures to accomplish the lift. The operational procedure is in addition to the Lift Plan.

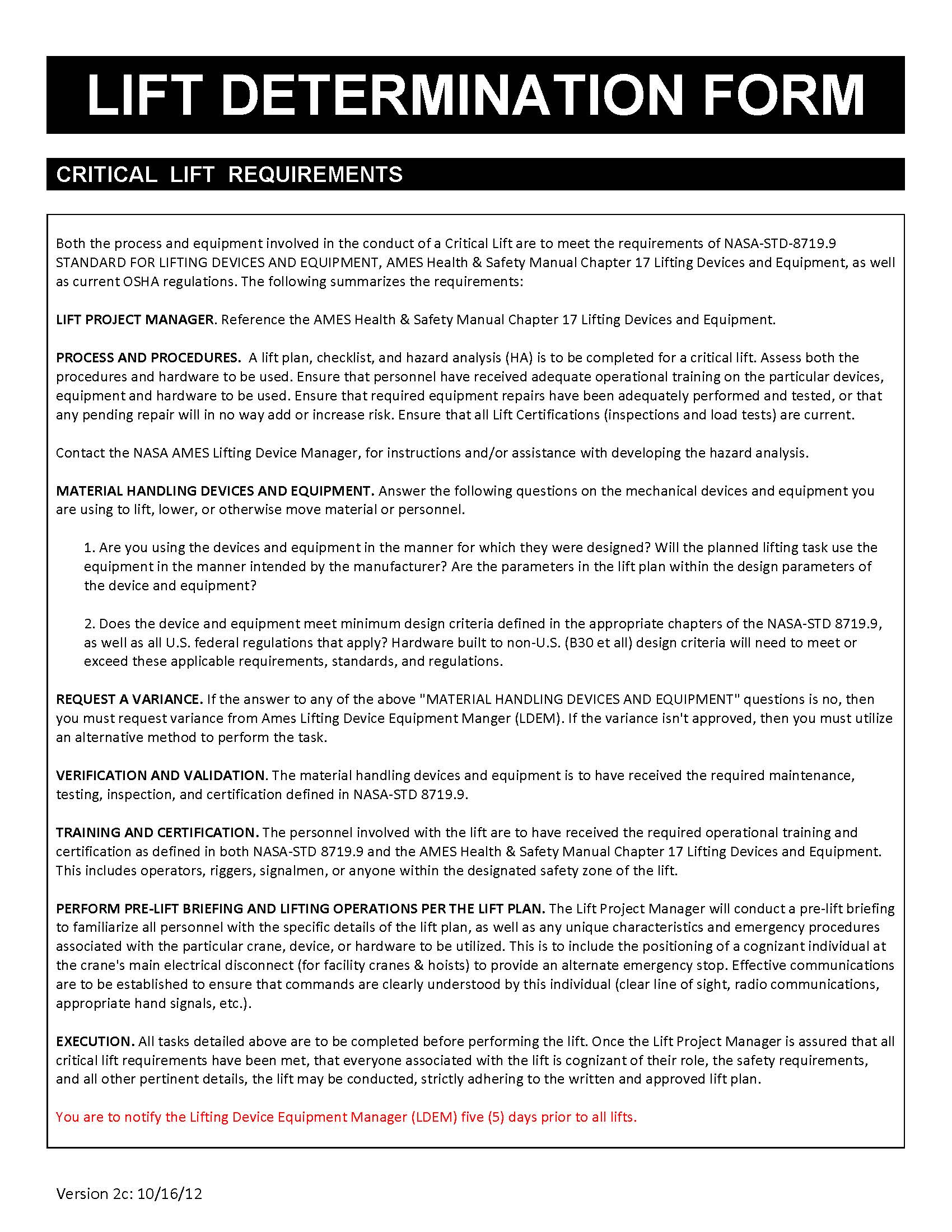

17.4.1 General Requirements for Critical Lifting Operations

- Critical lifts are lifts where failure/loss of control could result in loss of life, loss of or damage to flight hardware or lifts involving special, such as spacecraft, one-of-a-kind articles, or major facility components whose loss would have serious programmatic or institutional impact. Critical lifts also include the lifting of personnel with a crane, lifts where personnel are required to work under a suspended load and operations with special personnel and equipment safety concerns beyond normal lifting hazards.

- All personnel involved in critical lifting operations shall:

- Prepare and follow specific written procedures.

- Ensure one qualified person (NASA employee or contractor) is officially designated as responsible for the safety of the operations. That person may be a safety professional, a supervisor, an engineer or a task leader. This person is designated at the Safety Lift Observer (SLO).

- Ensure that overhead cranes used to lift or support flight hardware is labeled and tagged as specified in NASA-STD-8719.9 (Standard for Lifting Devices and Equipment).

- Ensure that overhead cranes are operated or used as specified in this chapter, OSHA 1910.179, OSHA 1910.184, ASME B30 series, Ames Safety Chapter 27 (Construction Safety Management) and NASA-STD-8719.9 (Standard for Lifting Devices and Equipment).

- Identify all hazards to include operations, maintenance, equipment, facility, anticipated loads, and human factors.

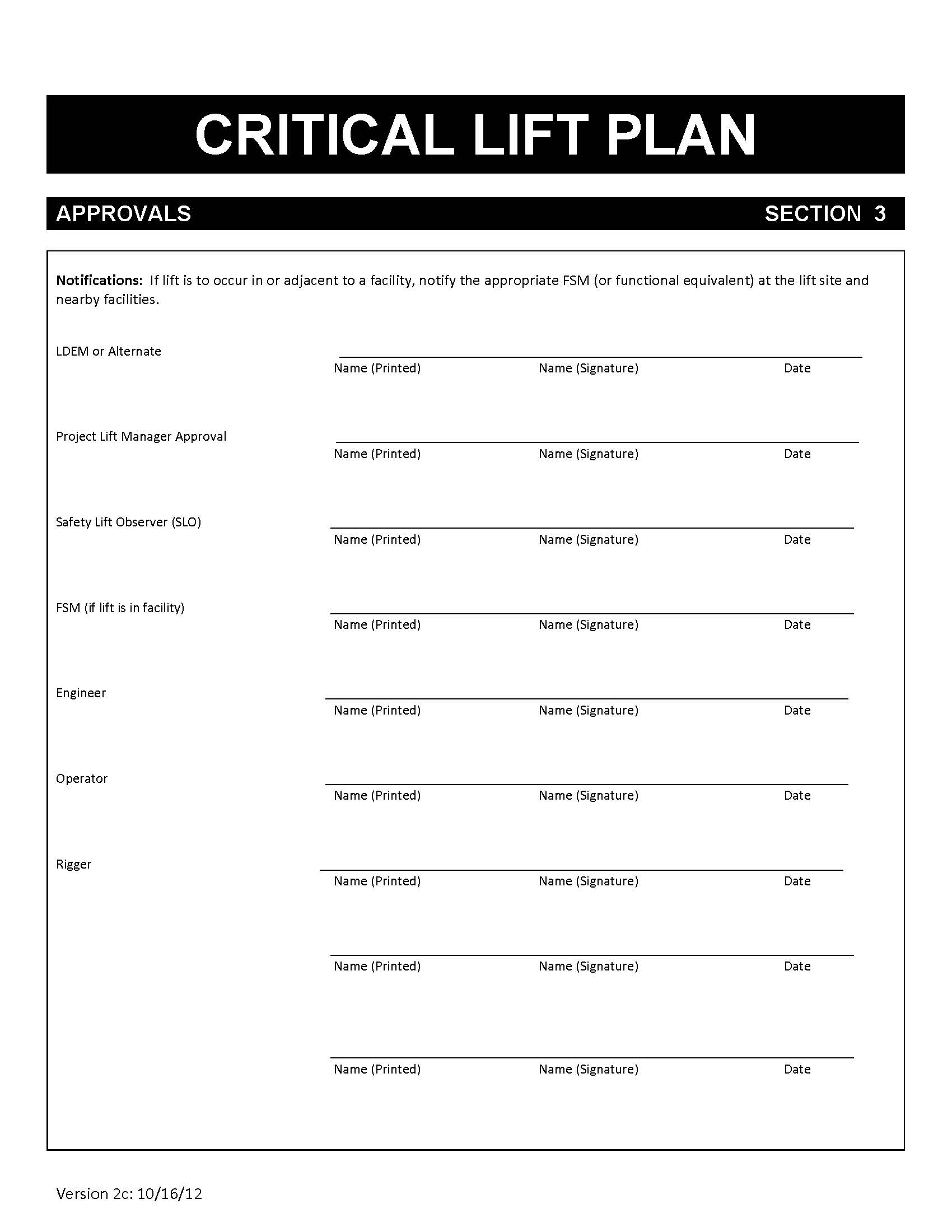

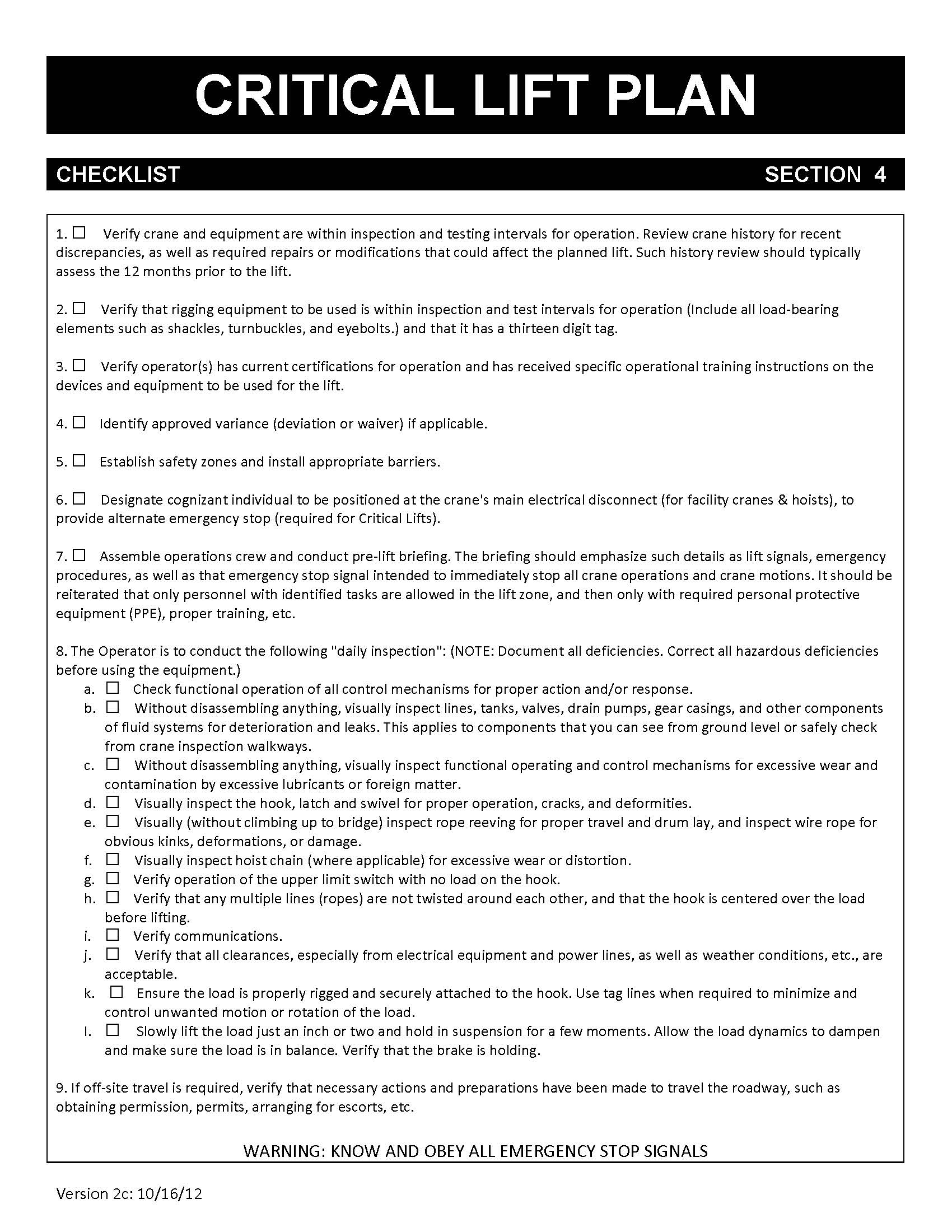

- Ensure that all critical lift documentation is completed and signed prior to operation.

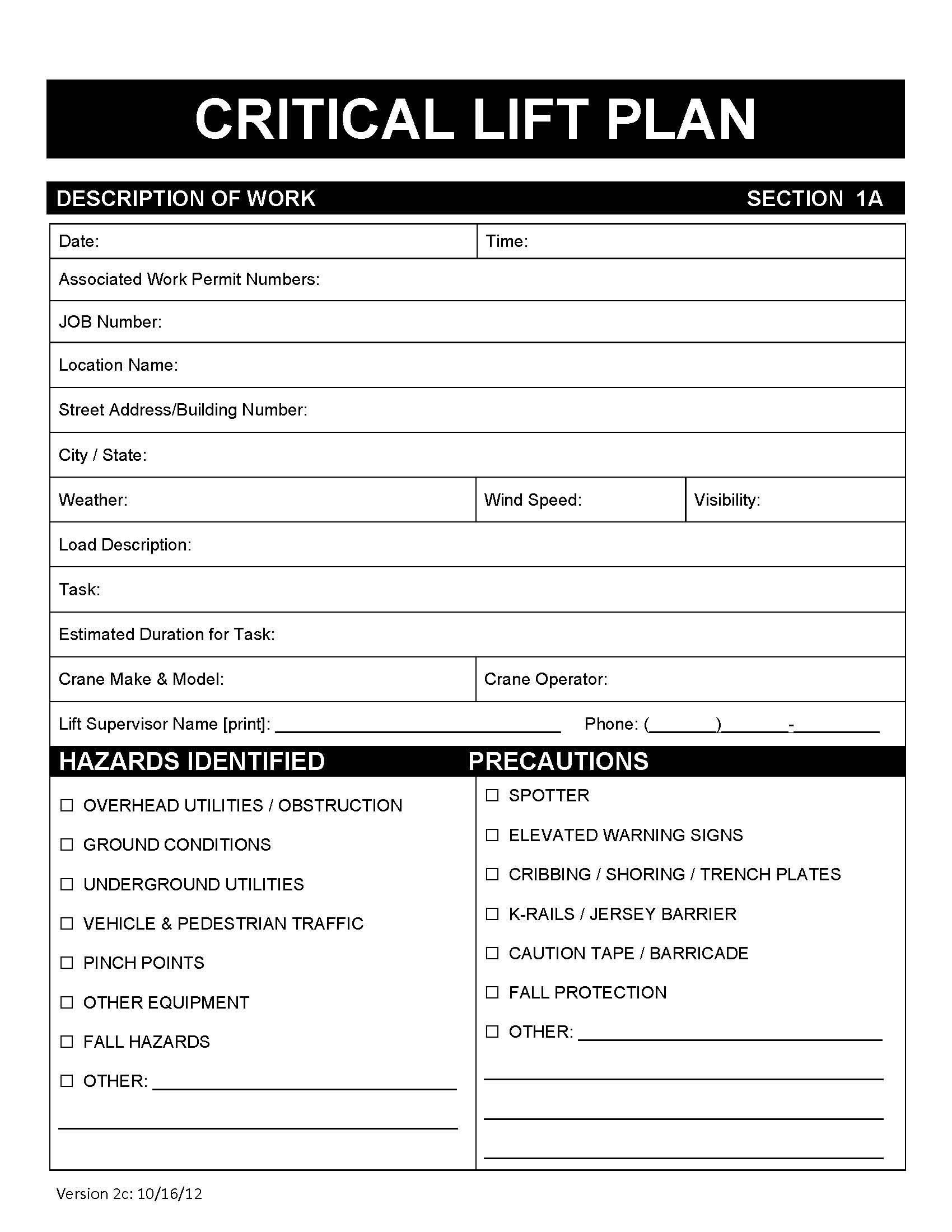

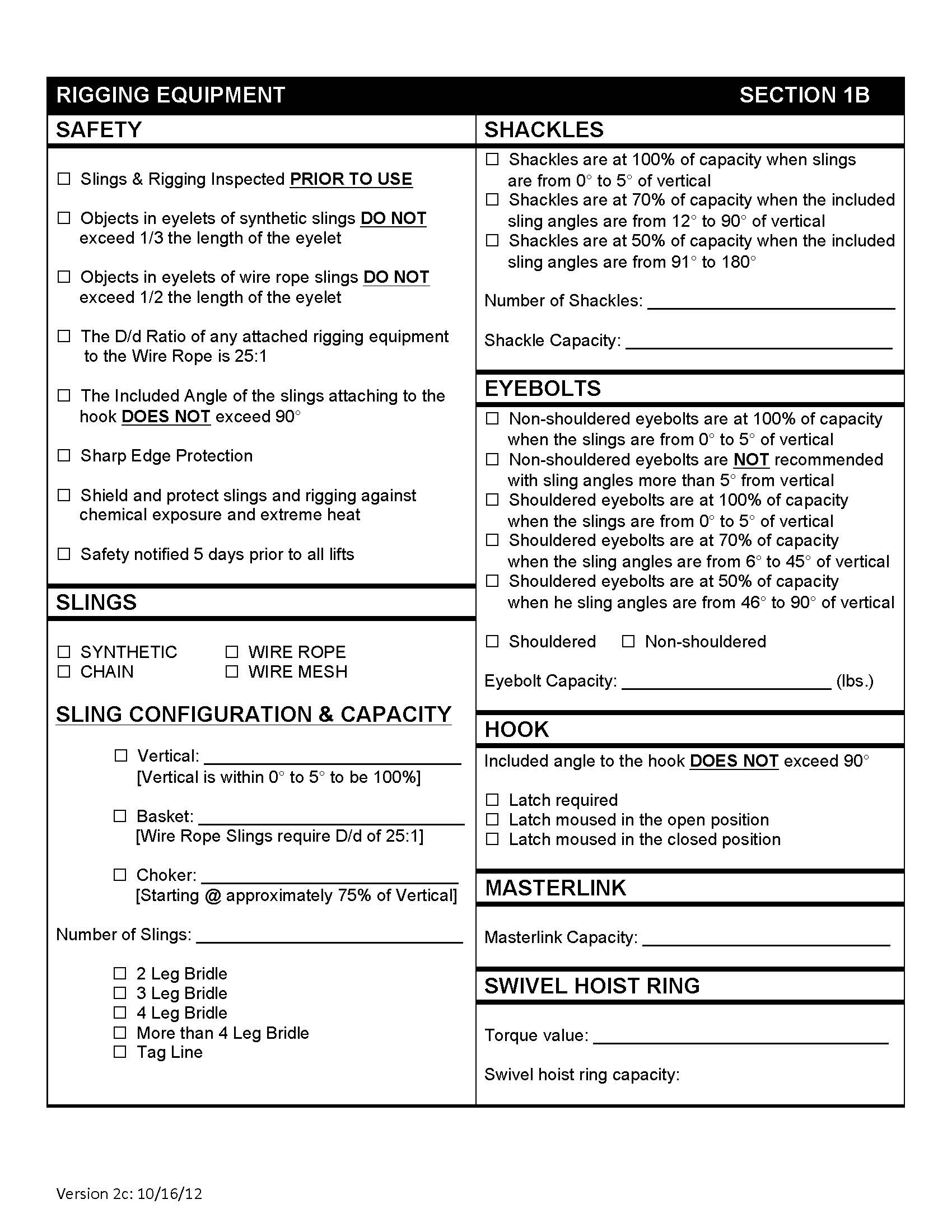

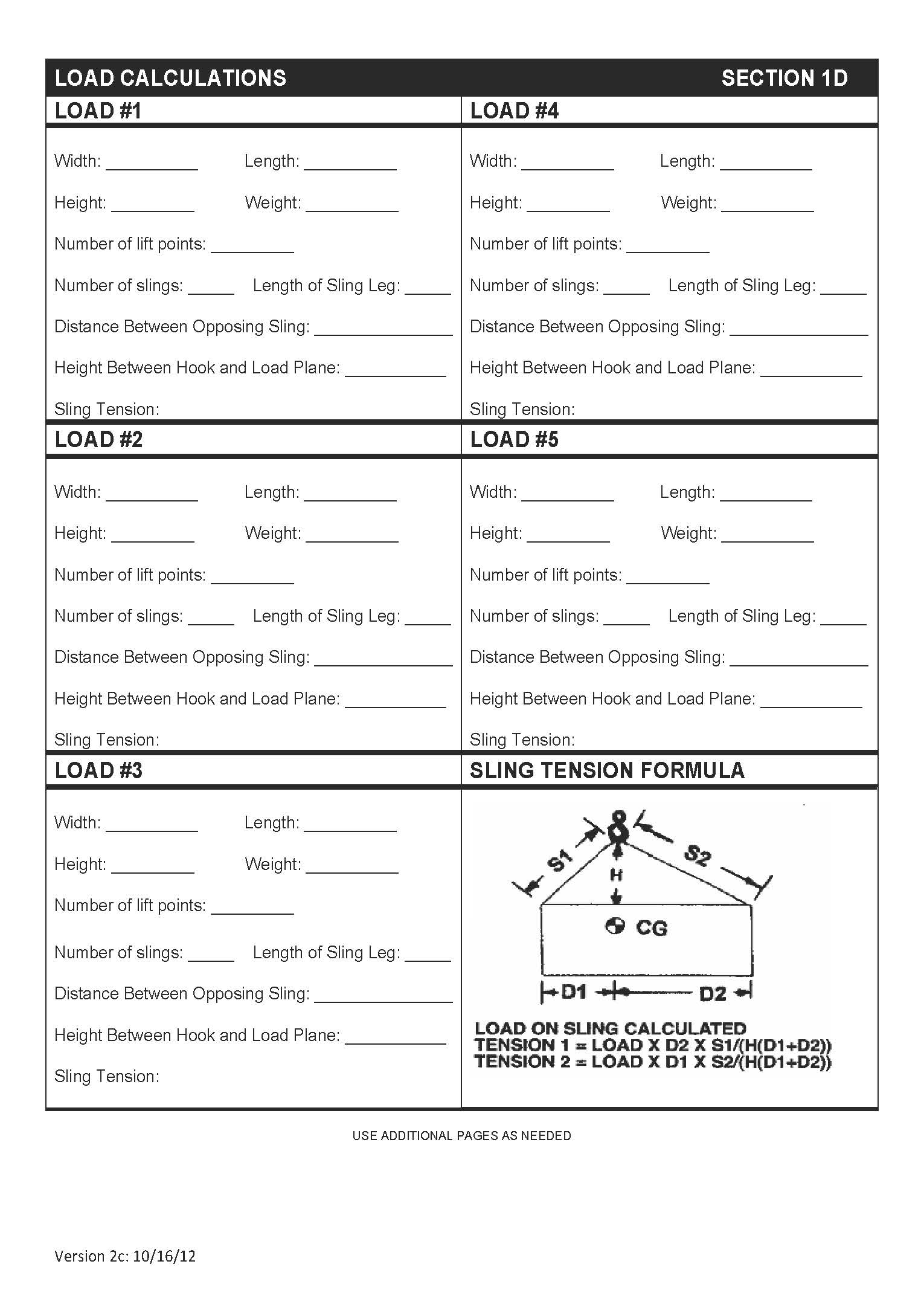

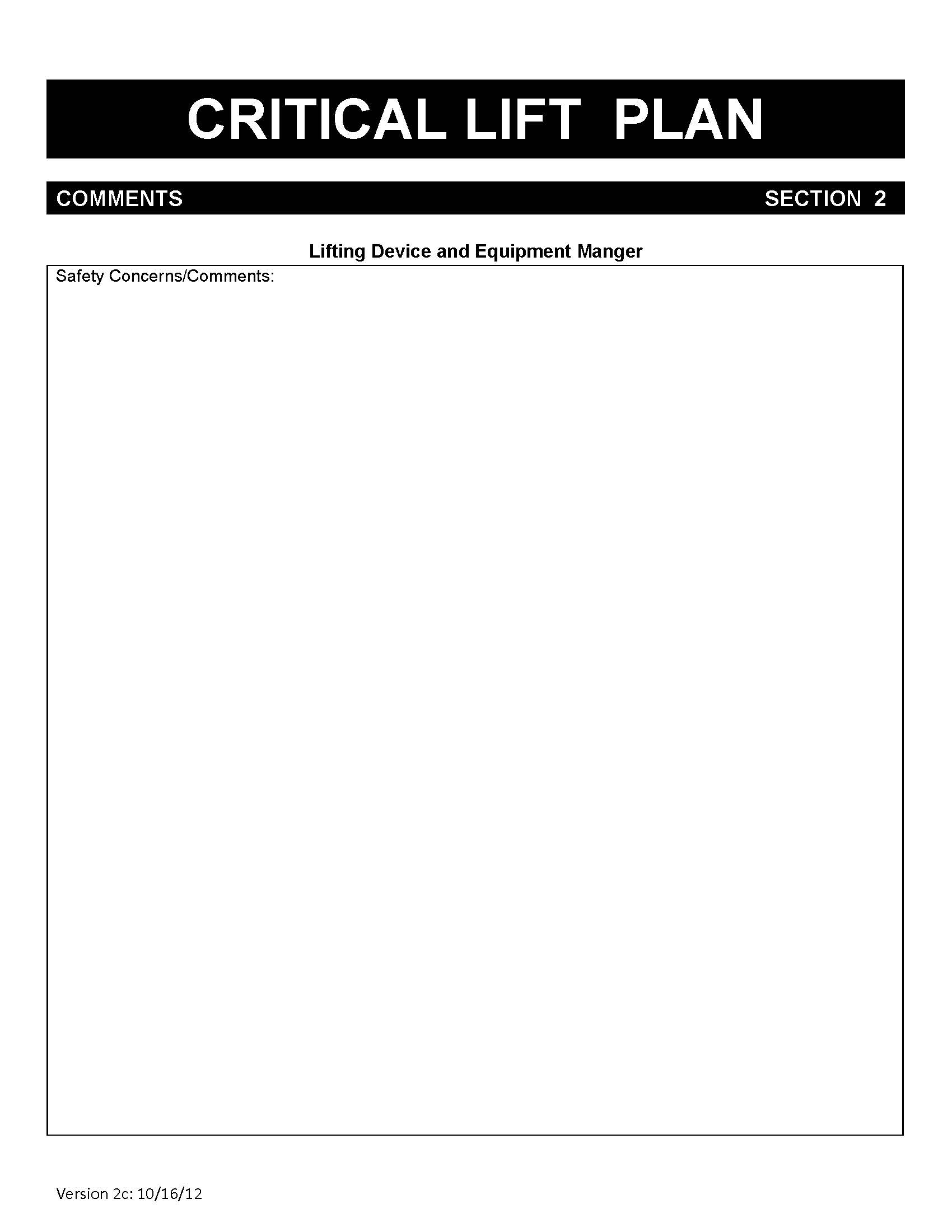

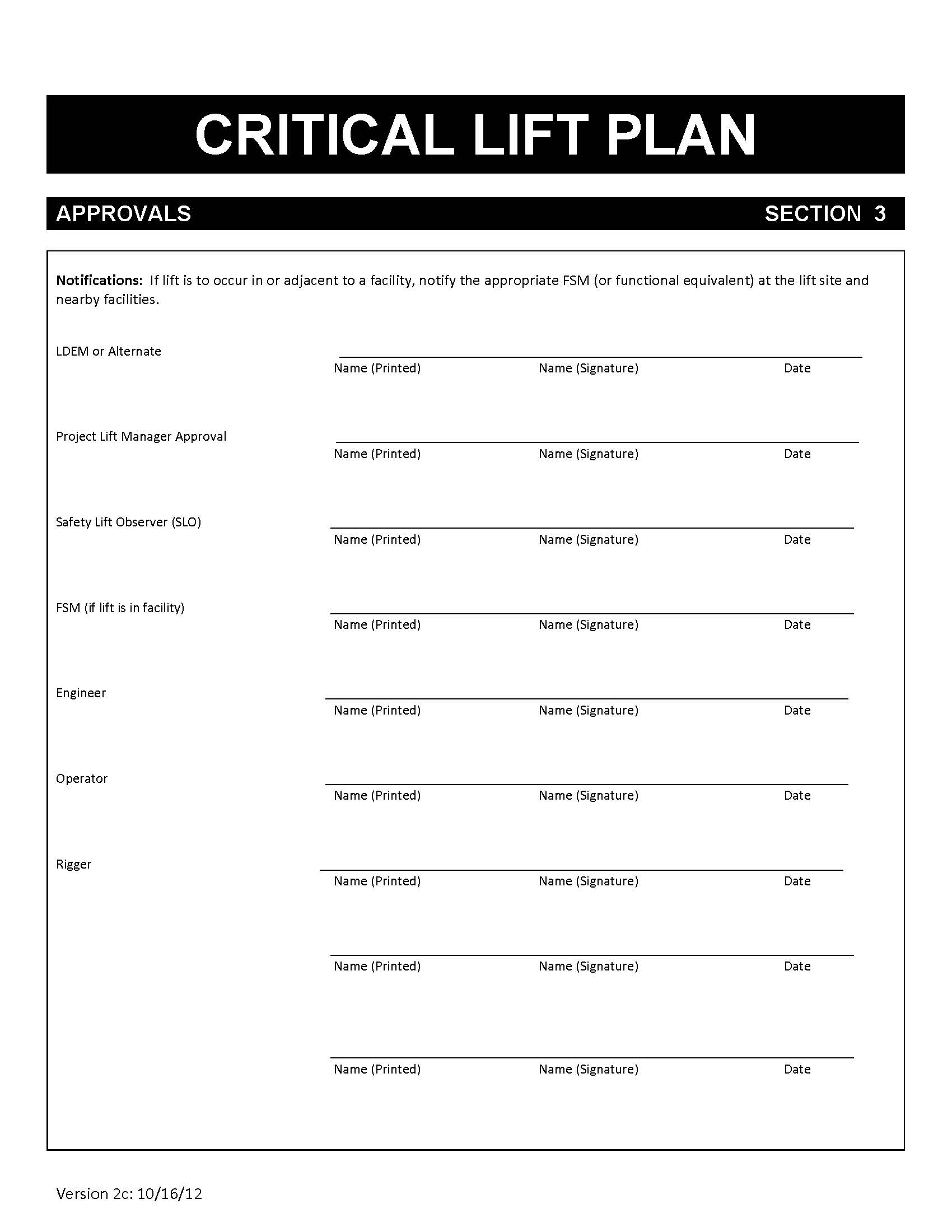

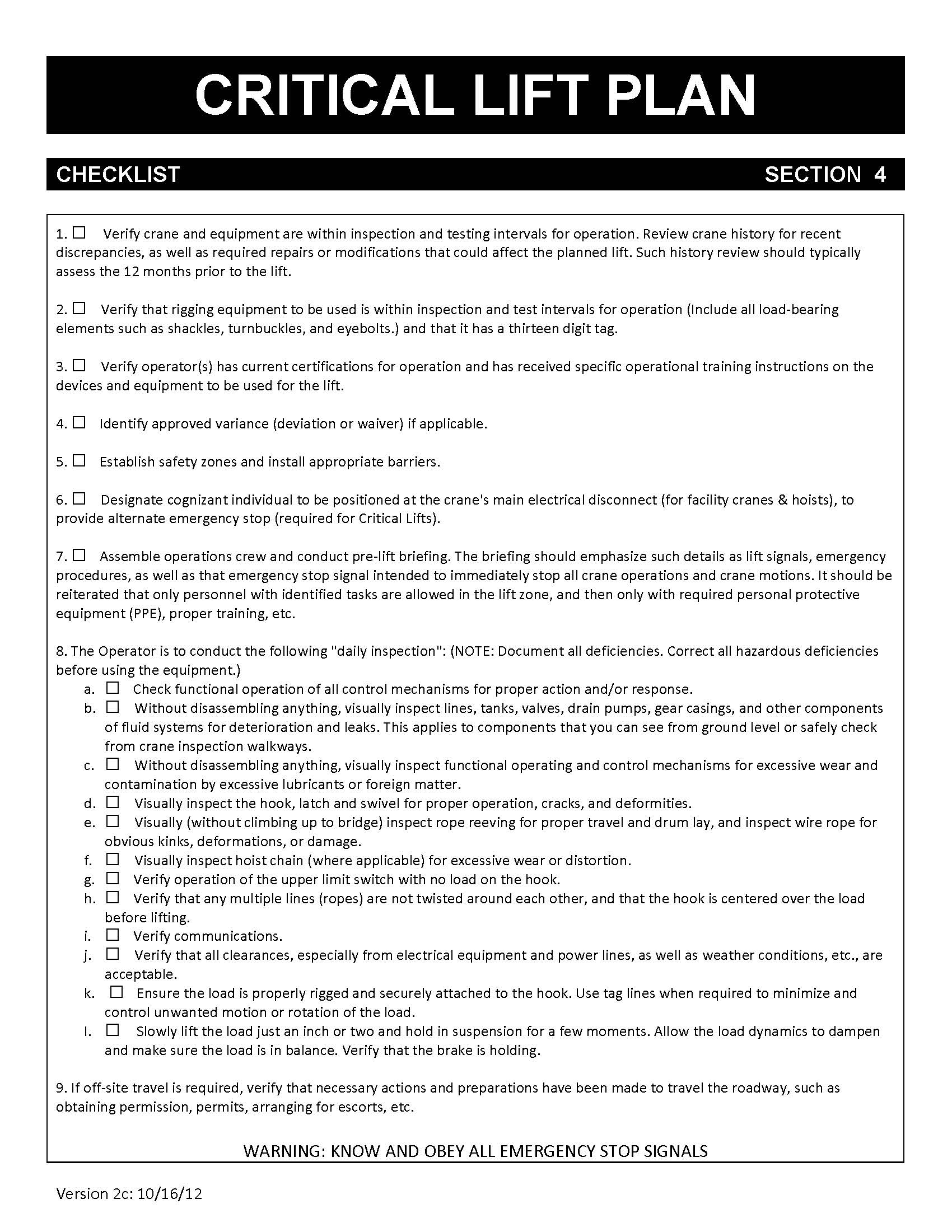

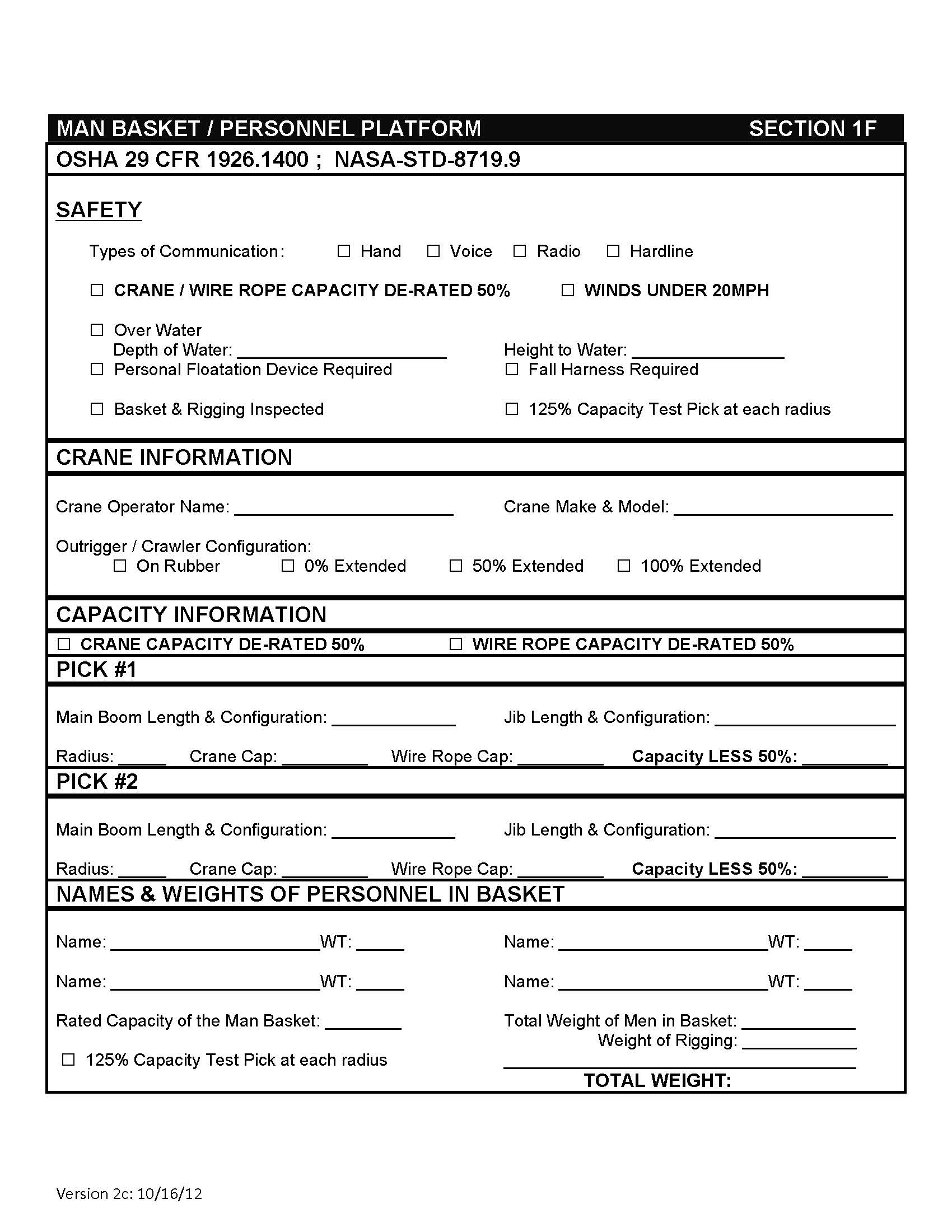

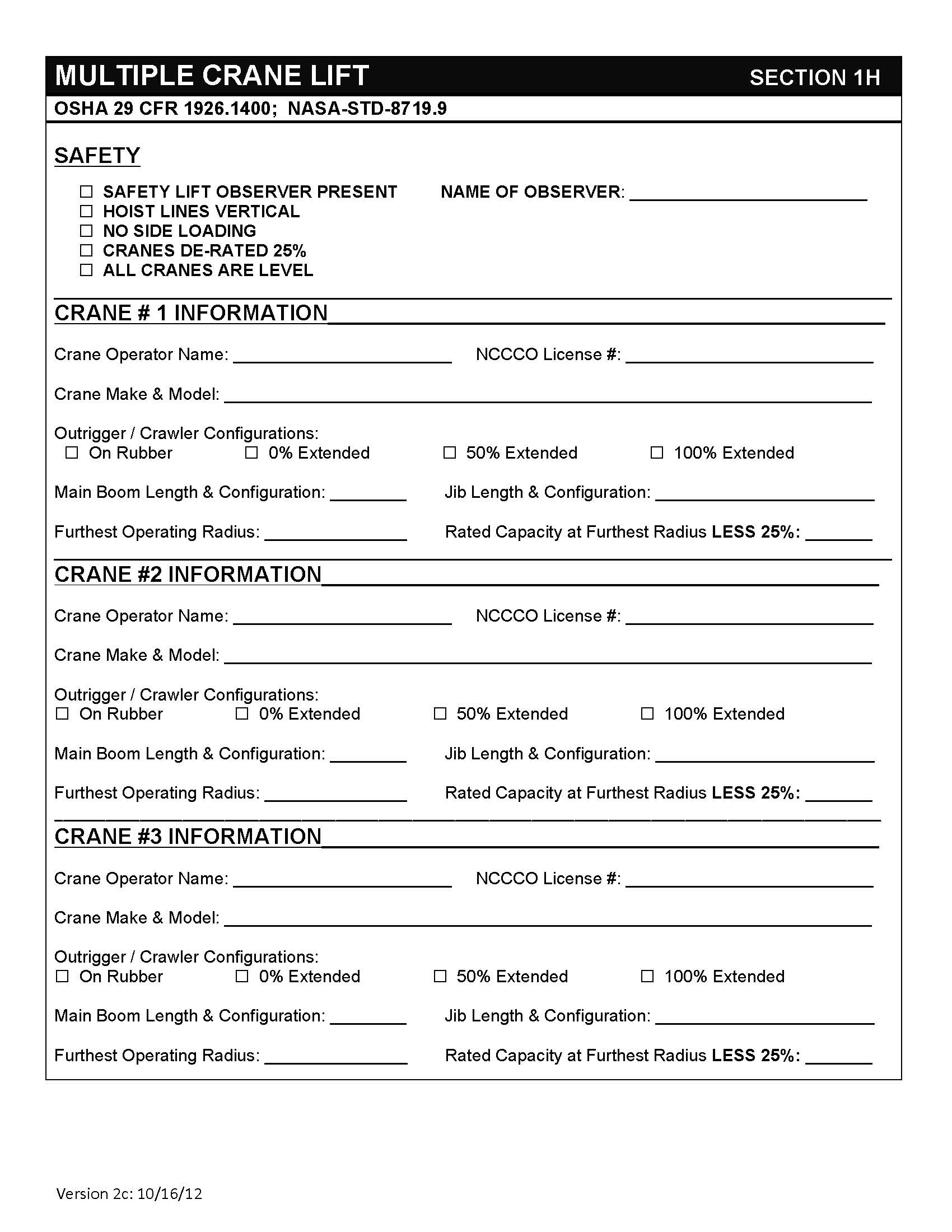

- See Appendix for Critical Lift Plan and associated forms.

17.4.1.1 Process to Identify Critical Lifting Operations

- The Lift Project Manager shall:

- At least five (5) days prior to the lift, complete the Lift Determination form in the appendix to determine the type of lift (critical or non-critical) requirements with the input of facility, program, user and safety and mission assurance personnel.

- Obtain approval & signatures required on the form.

- Distribute approved form:

- Lifting Device Equipment Manager (LDEM).

- Responsible person appointed for each lift.

- Safety Lift Observer (SLO).

- Provide a copy for use at the lift site.

17.4.1.2 Process to Initiate Critical Lifting Operations

- The Lift Project Manager shall:

- Ensure that a meeting takes place with all required personnel to discuss planned lifting operations, inviting the LDEM, the facility FSM, the crane operator, the owner (or owner's representative) of the items to be lifted, and representatives from the Health, Safety & Medical Services Division (QH).

- Ensure the crane operator presents an outline of the lift plan at this meeting.

- Present a Lift Determination form (see Appendix) in conjunction with a Hazard Analysis of the proposed lift at this meeting.

- Create an official record of this meeting with action items and general notes then distribute to all parties present.

17.4.1.3 Safety Analysis and Documentation of Cranes Used for Critical Lifts

- A recognized safety hazard analysis such as fault tree analysis, FMEA, Operating and Support Hazard Analysis (O&SHA), shall be performed on all cranes used for critical lifts and meet the following requirements:

- At a minimum, determine potential sources of danger, identify failure modes and recommend resolutions.

- Develop a system of risk acceptance for those conditions found in the hardware-facility-environment-human relationship that could cause loss of life, personal injury, and loss of or damage to the crane, facility, or load.

- Completed as part of the initial evaluation process for critical lift compliance and prior to use in a critical lift.

- Included in the crane documentation, and updated as required to reflect any changes in operation and/or configuration.

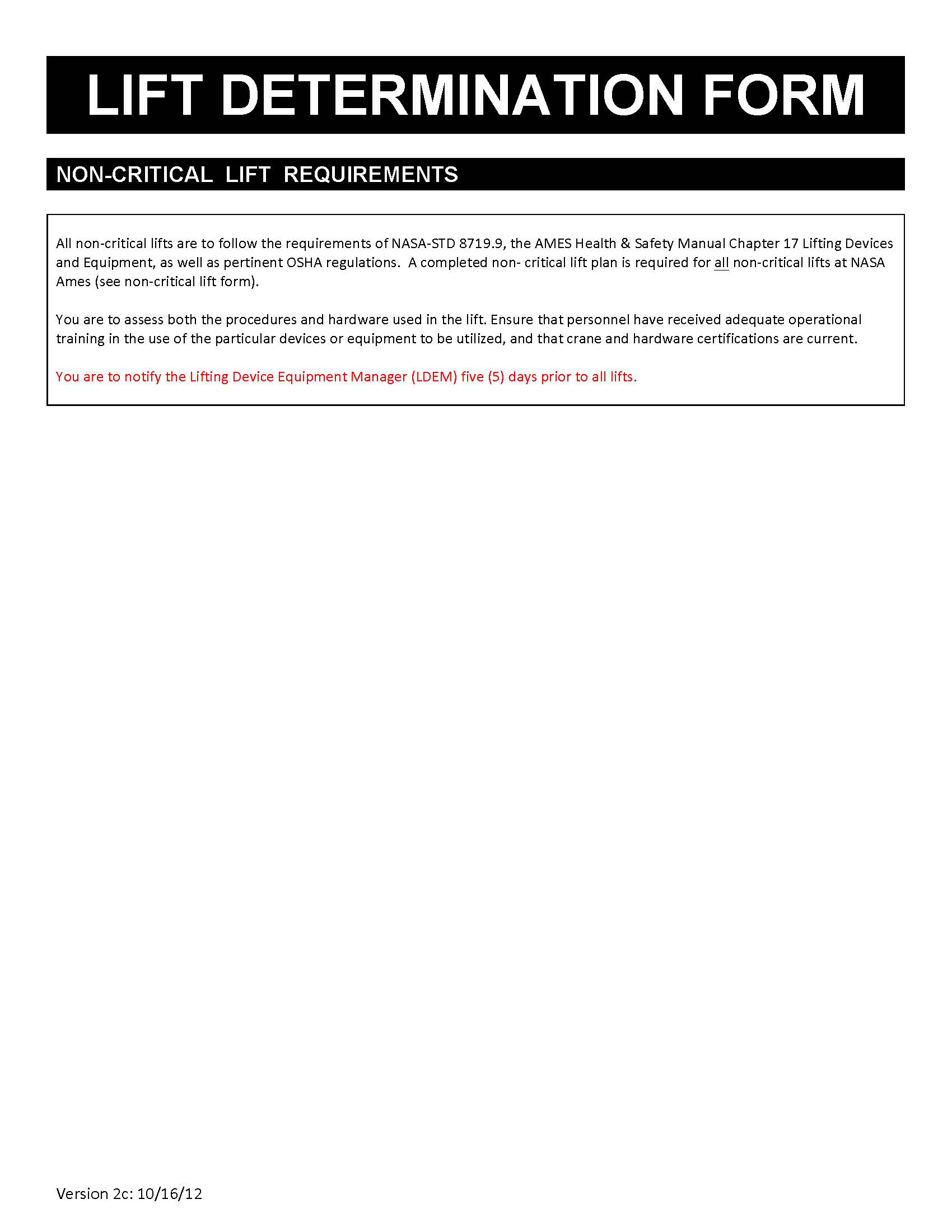

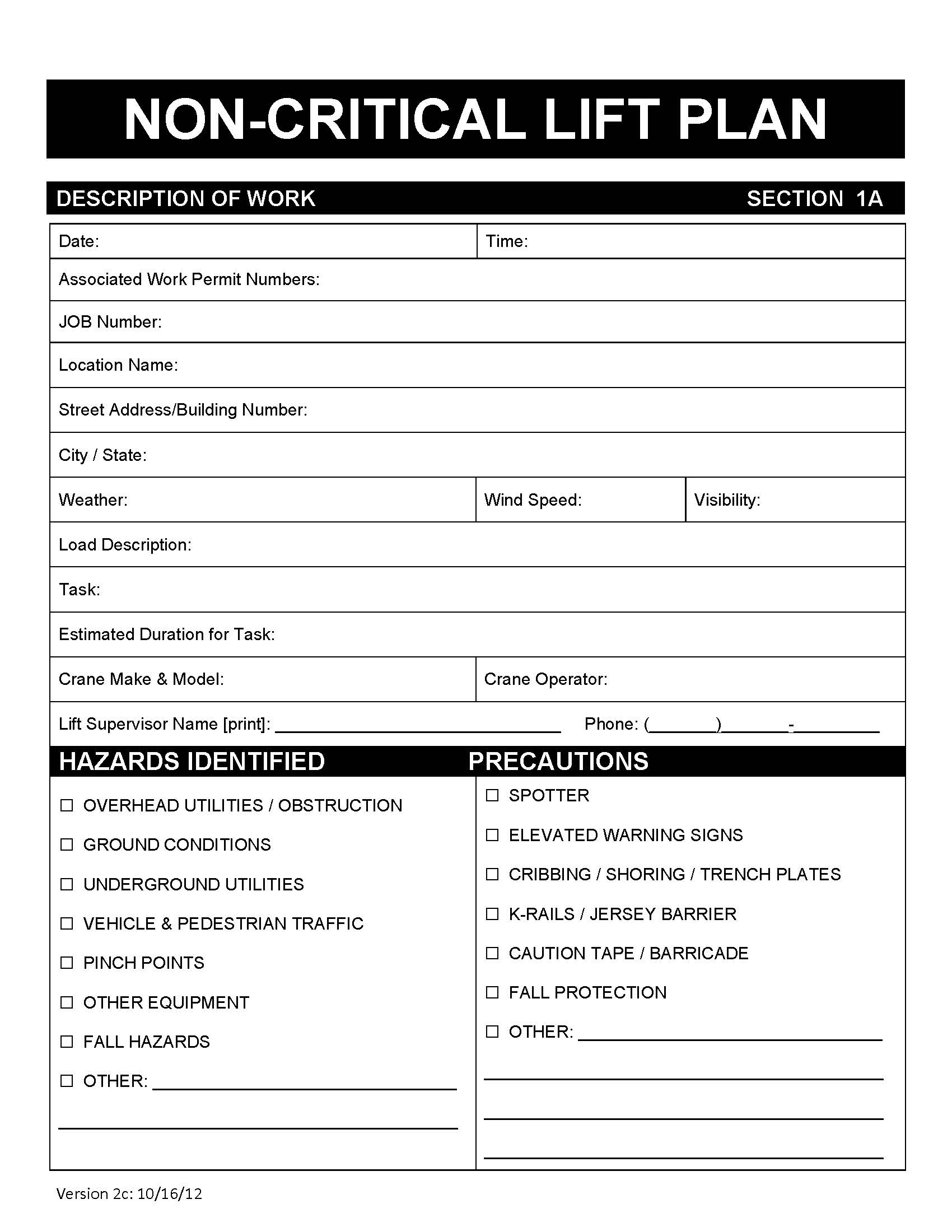

17.4.2 General Requirements for Non-critical Lifting Operations

- non-critical lifting operations involve routine lifting and are governed by standard industry rules and practices. All personnel involved in non-critical lifting operations shall:

- Not have personnel located under suspended or moving loads unless the operation adheres to the OSHA-approved NASA Alternate Standard for Suspended Load Operations NASA-STD-8719.9 (Standard for Lifting Devices and Equipment).

17.4.3 General requirements for Cab Operated Cranes

- Operators of Cab Operated Cranes shall:

- Ensure the operator's station is free of obstacles such as personnel belongings, clothing, tools or other necessary articles as to become obstacles in the safe operation of the crane.

- Ensure the operators do not carry items while climbing crane ladders. Hands will remain free. Articles will be lifted or engineered in a safe means up to the operator.

- Ensure that a five (5) pound ABC fire extinguisher is inside or in the immediate vicinity of the operators cab.

17.4.4 Load Test and Inspection Requirements

- Three types of load tests are required for overhead cranes.

- Before first use and after installation, all new, extensively repaired, extensively modified, or altered cranes shall undergo a proof load test with a dummy load as close as possible to, but not exceeding 1.25 times the rated capacity of the crane.

- Each crane shall be tested at least once every 4 years with a dummy load equal to the crane's rated capacity. Cranes used for critical lifts shall be load tested at least once per year.

- Performed in conjunction with proof load and periodic load tests, the operational test typically moves the load through a full range of movement to determine if the equipment (limit switches, emergency stop controls, brakes, etc.) is functioning properly.

- The proof load tests and operational tests are to be performed prior to first use for new cranes and for existing cranes that have had modifications or alterations performed to components in the load path. Repairs or alterations to nonlifting, secondary lifting, or holding components such as suspension assemblies, electrical system, crane cab, etc., do not require a load test, although a functional check should be performed to determine if the repairs or alternations are acceptable.

- All load and operational tests are to be performed by qualified personnel according to written (specific or general) technical operating procedures. An inspection of the crane and lifting components will be performed after each load test and prior to the crane being released for service to ensure there is no damage. Surface or volumetric nondestructive testing (NDT) of critical components is used to validate the existence or absence of cracks or other load test effects indicated by this inspection. The periodic load test requirement may be fulfilled by a concurrently performed proof load test.

- There are three types of inspections for cranes.

- These inspections are to be performed and documented using a Pre-Operational Checklist/Daily Inspection form (see Appendix) by the qualified operator prior to first use each day the crane is used and kept on file in the area and will include the following: check operating and control mechanisms for proper function. Without disassembling, visually inspect lines, tanks, valves, drain pumps, gear casings, and other components of fluid systems for deterioration and leaks. This applies to components that can be seen from the ground level for floor operated cranes and cab operated cranes or for which there is safe access via crane inspection walkways for cab operated cranes. Without disassembling, visually inspect all functional operating and control mechanisms, including brakes where visible, for excessive wear and contamination by excessive lubricants or foreign matter. Visually inspect hooks for cracks and deformities. Visually (without climbing up to bridge) inspect rope reeving for proper travel and drum lay, and inspect wire rope for obvious kinks, deformation, wire clips, and/or damage. Visually inspect hoist chains for excessive wear or distortion.

- Monthly inspections (frequent inspections):

- These are formal inspections performed by the maintenance contractor.

- To include all items in daily inspection plus inspection for wear, twist, distortion, or stretch of hoist chains if applicable; a thorough inspection of all ropes; inspection for visible deformation or cracks in hooks. A thorough inspection of the wire rope includes a check for reductions of nominal diameter (measured with a caliper or go/no-go gage) or damage to the wire rope from the drum to the load block, with the load block in its lowest elevation (providing a minimum of two wraps of wire rope are left on the drum).

- Annual inspections (periodic inspections):

- These are formal inspections performed by the maintenance contractor.

- After each formal inspection by an outside agency, qualified authorized personnel of the agency are to prepare written, dated and signed inspection reports. These reports will include a reference to the inspection procedure and adequacy of the crane and crane components. Inadequacies are to be documented and, if determined to be a hazard, corrected prior to further use. These reports are to be filed and be made readily available by the organizational element responsible for crane inspection.

17.4.5 Standard System of Labeling

- The Lifting Device Equipment Manager (LDEM) shall ensure that cranes have a permanently affixed tag (red for critical lift use and for non-critical) with the following information:

- Thirteen digit equipment part number that has been assigned through the MAXIMO database.

- Next certification due date taking into account critical or non-critical use.

- Rated capacity of crane (WLL - Working Load Limit).

- Are plainly marked on both bridge and/or trolley sides of the crane and correspond with the operator station or pendant control. Should the crane have multiple hoisting units, each unit load blocks will be clearly marked, visible from the floor and operators view.

17.4.6 Standard Lockout/Tagout System

- Personnel working with cranes shall ensure:

- That administrative locking is applied when inspection discrepancies, ongoing maintenance operations or other issues are discovered, including expired certification, by following the NASA Ames Health and Safety Manual Chapter 31 (Administrative Locking section).

- The tag will state the discrepancy or issue, date, person applying the tag and contact information.

- The tag will be applied to the electrical disconnect or breaker in a durable manner.

- The only tag used is to be yellow colored and read "Caution, Special Condition”.

- A lock is to be used in addition to the tag however it may not be red in color.

- If the item or equipment will not receive a lock, a tag may be used alone and must be securely attached with a one-piece, all-environment-tolerant nylon cable tie in a manner so it cannot be inadvertently or accidentally detached.

- Administrative locking and/or tagging will not be used as a means of protection during a servicing, maintenance, or modification procedures, and is not a substitute for lockout and/or tagout. See the NASA Ames Health & Safety Manual Chapter 31 (Lockout/Tagout) for specific procedures to follow.

- The crane is not used until the original discrepancy causing application of the administrative locking has been resolved.

17.4.7 Documentation and Records

- Records such as proof tests, load tests, operational tests, inspections, and audits of the lifting safety program shall be maintained in accordance with APR 1440.1, NASA Ames Research Center Records Management Program Requirements and the NASA Records Retention Schedule.

- Formal inspection records are kept on file with the Lifting device Equipment Manager (LDEM).

- Non-Formal inspection records are kept and made readily available by the organizational element responsible for crane inspection.

17.4.8 Operating Procedures for Emergencies

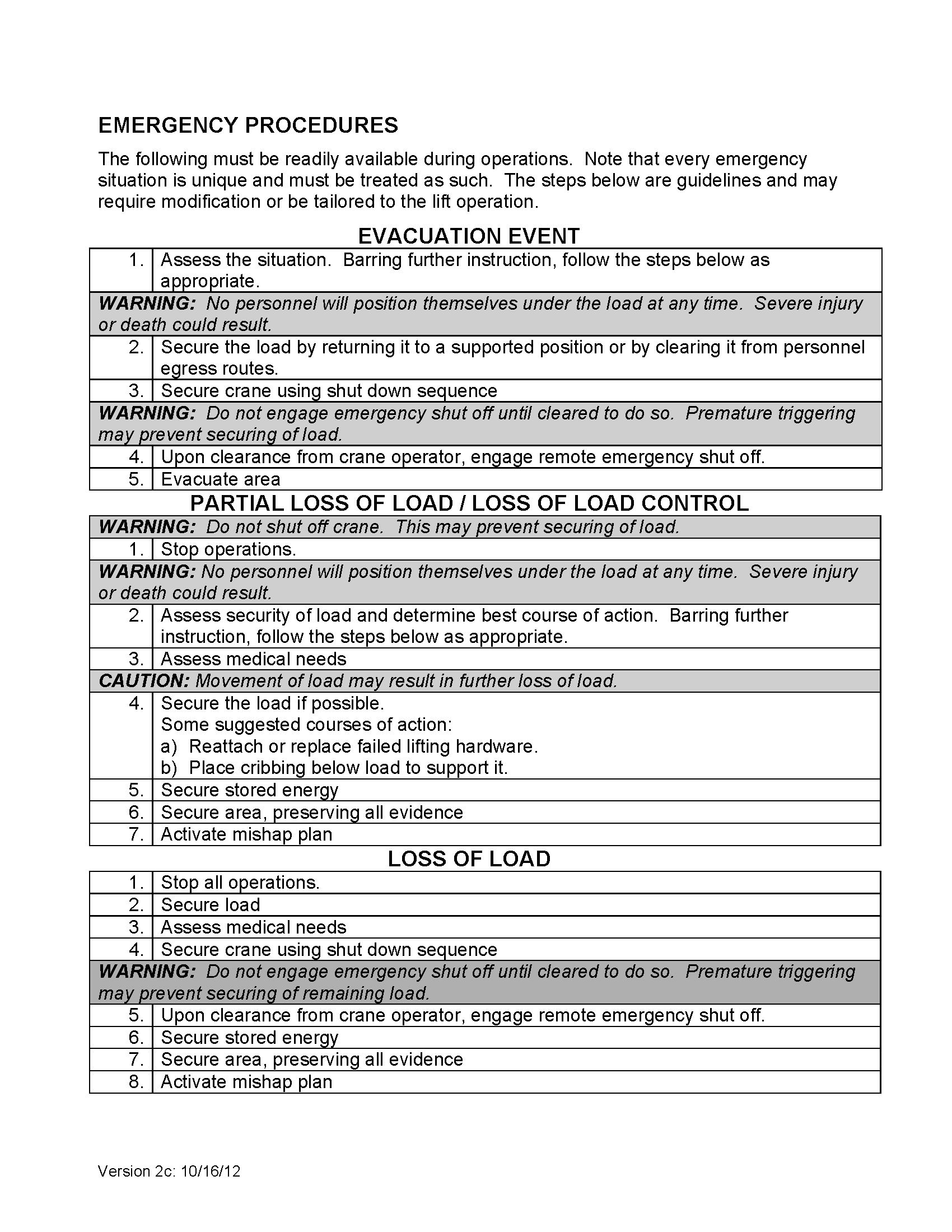

- These procedures may be part of the lift plan or a separate document such as in the Emergency Procedures checklist found in the Appendix.

- All lifts shall follow the procedures below at a minimum:

- Evacuate the immediate area around any suspended load.

- Place barriers or caution tape to isolate area under the load.

- Apply Administrative locking and notify the LDEM for repair.

- Call 911 from an Ames phone or 650-604-5555 from a cell phone and report the emergency.

- Suspend all outside crane operations during thunderstorms.

17.4.9 Documenting Crane Problems and Discrepancies

- Discrepancies and crane problems are documented using the daily inspection form. Evidence of correction is to be kept with the daily inspection form for one (1) year.

- Operators are to review the daily inspection forms to ensure that issues identified have been corrected prior to using the equipment and to determine possible impact on planned activity.

17.4.10 NASA Alternate Standard for Suspended Load Operations

- NASA-STD-8719.1 contains an alternate standard for operations where employees may work under a suspended load. This standard applies to specifically identified operations controlled by the National Aeronautics and Space Administration (NASA) involving both civil service and contractor employees. The standard is an alternate to Code of Federal Regulations 29 CFR 1910.179(n)(3)(vi), 29 CFR 1910.180(h)(3)(vi), and 29 CFR 1910.180(h)(4)(ii).

17.4.11 Special Precautions While Handling Explosives or Electro-Explosive Devices (EEDs)

- For DOT packaged explosives, Safety personnel will be made available. Barricades and warning signs will be erected to control access.

- Explosives and EEDs that are not within DOT approved containers will be handled in accordance with approved hazardous operations procedures. In addition to system configuration controls, these procedures shall address:

- Voltage checks on crane hooks that will handle explosives or EEDs will be performed prior to the start of operations; including when crane is in motion.

- The grounding of the crane hook prior to connecting to explosives or EED's for static sensitive systems. If a ground connection will be disconnected to facilitate operations, an alternate ground should be connected prior to disconnecting the existing ground. The final attachment/detachment will need to be at least 10 feet (3 m) from exposed propellant grain, explosives, or EEDs.

- The danger potential for radio transmissions near explosives will be evaluated prior to the operation.

- Personnel limits, protective clothing, warning signs and barricades.

- Safety surveillance and inspections will be established as requirements.

[Back to Table of Contents]

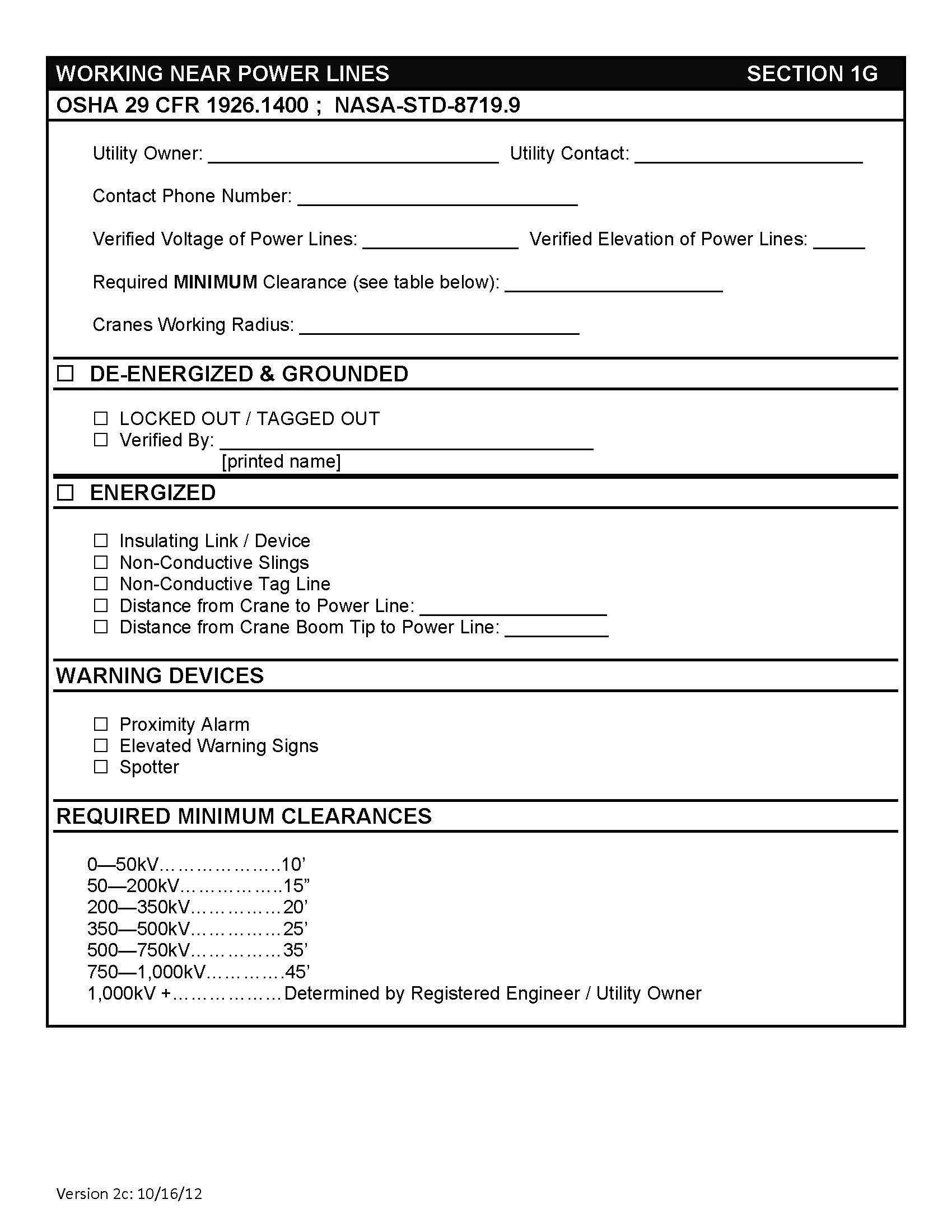

17.5 Mobile Cranes, Derricks, Hoists and Winches

- High quality off the shelf OEM-type equipment is acceptable for critical and non-critical lifts if it is designed, maintained, and operated according to this standard.

- Personnel shall document any deficiency found during the pre-operational check and remove from service using administrative locking until steps are taken to correct deficiency.

17.5.1 General Requirements for Mobile Cranes and Derricks

- Personnel working with mobile cranes and derricks shall:

- Follow 29 CFR 1926.1400 (cc) for mobile cranes.

- Ensure that mobile cranes meet the performance, structural, mechanical, and electrical design requirements provided in NASA-STD-8719.9 (Standard for Lifting Devices and Equipment).

- Ensure that mobile cranes used to lift or support flight hardware are labeled and tagged as specified in NASA-STD-8719.9 (Standard for Lifting Devices and Equipment).

- Ensure that mobile cranes are operated or used as specified in this chapter, OSHA 1926.1400, OSHA 1910.179, OSHA 1910.184, ASME B30 series, Ames Safety Chapter 27 (Construction Safety Management) and NASA-STD-8719.9 (Standard for Lifting Devices and Equipment).

- Ensure load charts are posted in the cabs or centrally located and equipment is not operated unless one is available.

- Ensure that mobile cranes are level and outriggers are fully extended per weight chart specifications.

- Ensure that floats under out-rigging will be strong enough to prevent crushing, bending or failure and prevent toppling.

- Ensure that loads will not be lifted over the cab on truck mounted cranes unless approved by manufacturer.

- Ensure that two (2) full wraps of wire rope remain on the drum despite lowered angle of the boom.

- Ensure that cranes in transit will follow precautions recommended by the manufacturer.

- Ensure that the crane is positioned so that it will not contact or fall across a power line in the event of a equipment failure.

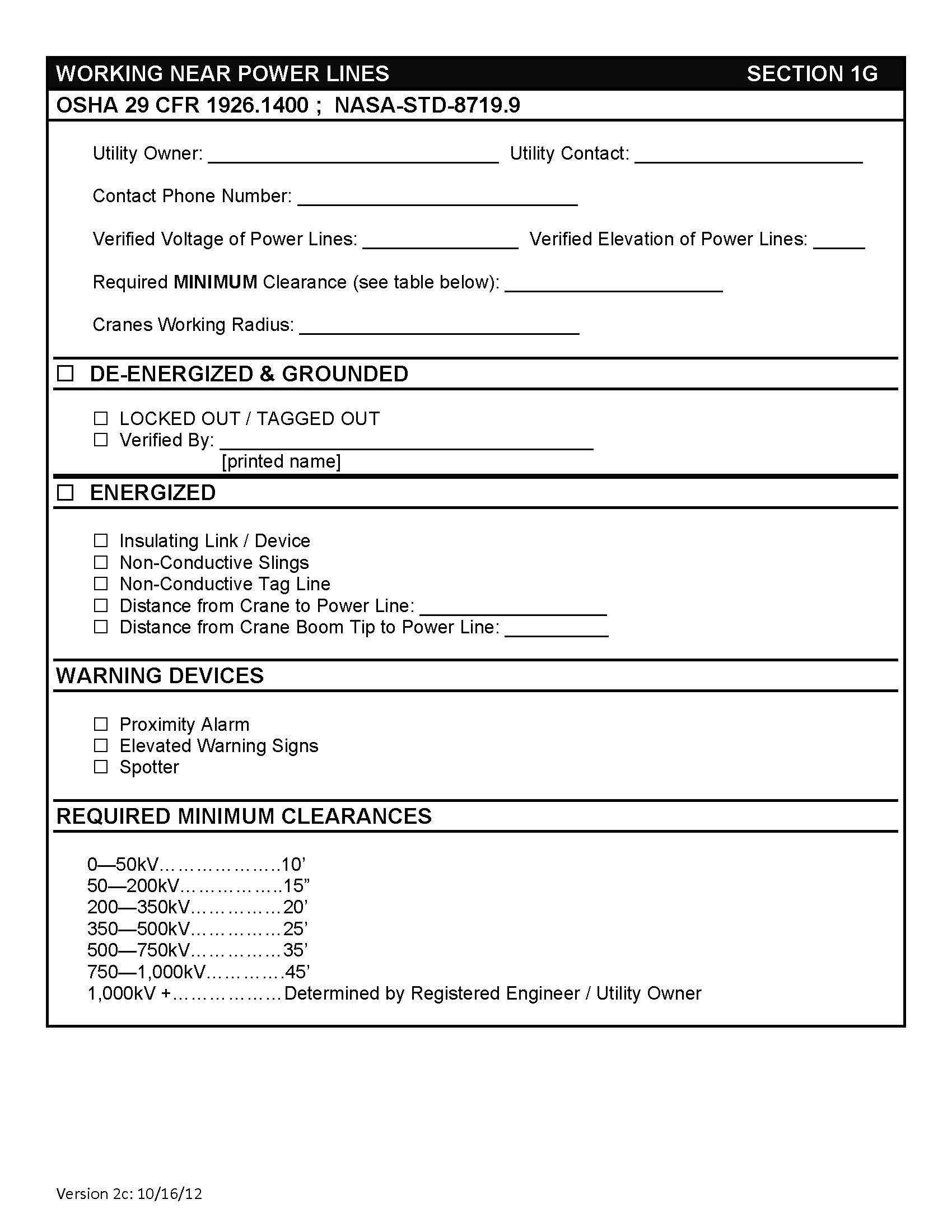

- Ensure that work near or around power lines will follow distance requirements of ASME B30.5.

- Ensure that appropriate load charts shall be located in the crane and derrick cab, if so equipped. Otherwise, the load charts are to be kept in a central, easily accessible place. Mobile cranes and derricks are not to be operated without an appropriate load chart.

- Ensure that outriggers are set to remove the machine weight from wheels if required by the OEM per load rating chart. Blocking under outrigger beams is not permitted. Blocking under outrigger floats, when used, is required to be strong enough to prevent crushing, bending, or shear failure and of sufficient thickness, width, and length as to completely support the float, transmit the load to the supporting surface, and prevent shifting or toppling under load.

- Ensure that Outriggers are used when the load to be handled at a particular radius exceeds rated load without outriggers, as specified by the crane manufacturer's load chart. Floats, where used, are to be securely attached to the outriggers.

- Ensure that loads are not lifted over the front area of a truck mounted crane except as approved by the crane manufacturer.

- Ensure that when traveling a mobile crane with a load, a person is designated responsible for determining and controlling safety and making decisions as to position of load, boom location, ground support, travel route, and speed of movement.

- Ensure that a mobile crane with or without a load is not traveled with the boom so high that it may bounce back over the cab.

- Ensure that if the load is to remain suspended for any considerable length of time, the operator will hold the drum from rotating in the lowering direction by activating the positive control lever of the operator's station.

- Ensure that mobile cranes are not operated without the full amount of ballast or counterweight in place as specified by the manufacturer. The ballast or counterweight, as specified by the manufacturer, is not to be exceeded.

- Ensure that refueling with small portable containers is done with Underwriter's Laboratories or Factory Mutual Laboratories approved (or equivalent) safety type can equipped with an automatic closing cap and flame arrestor. Machines are not to be fueled with engines running.

- Ensure that safety equipment is available and worn to include: gloves, hard hats, safety glasses, safety shoes and vests or other PPE as indicated in the approved lift plan.

- Should significant issues or problems arise during the lift, a debriefing will be held to discuss the problems and lessons learned. See the Lessons Learned section in this chapter for additional information.

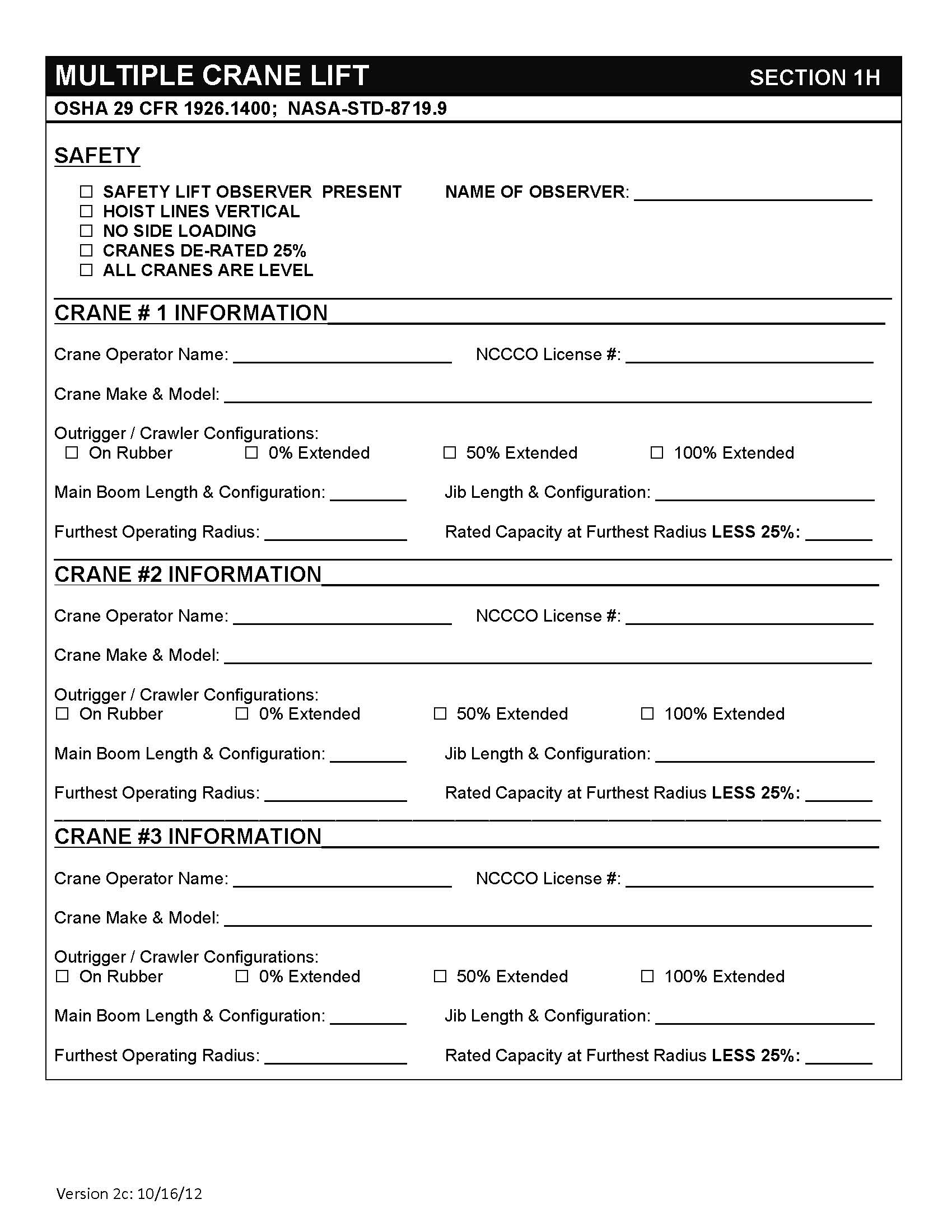

- Personnel working with Mobile Cranes, Derricks, Hoists & Winches will complete the Lift Determination form from the Appendix to determine if the lift is classified as critical or non-critical five (5) days prior to the lift and then submit to the Construction Project Manager.

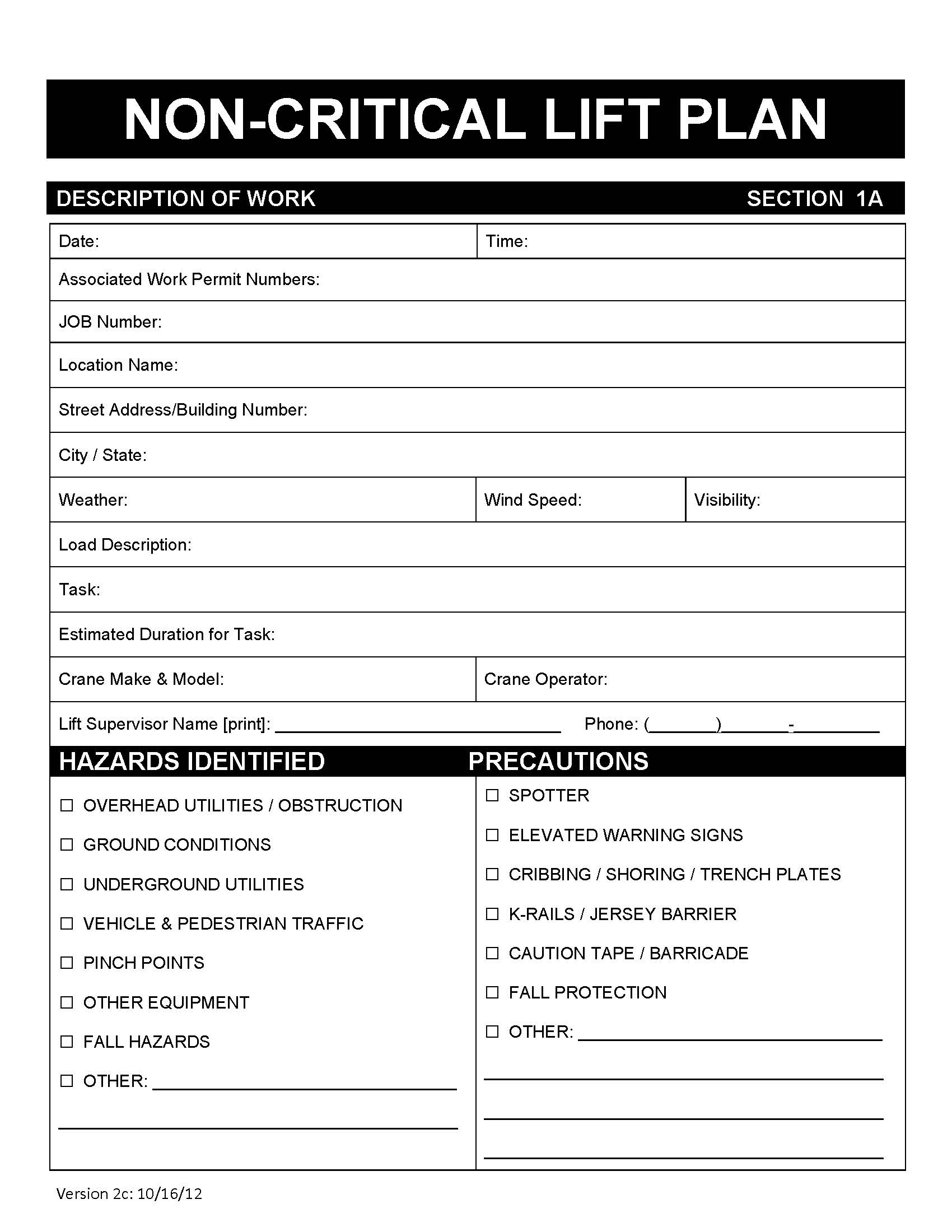

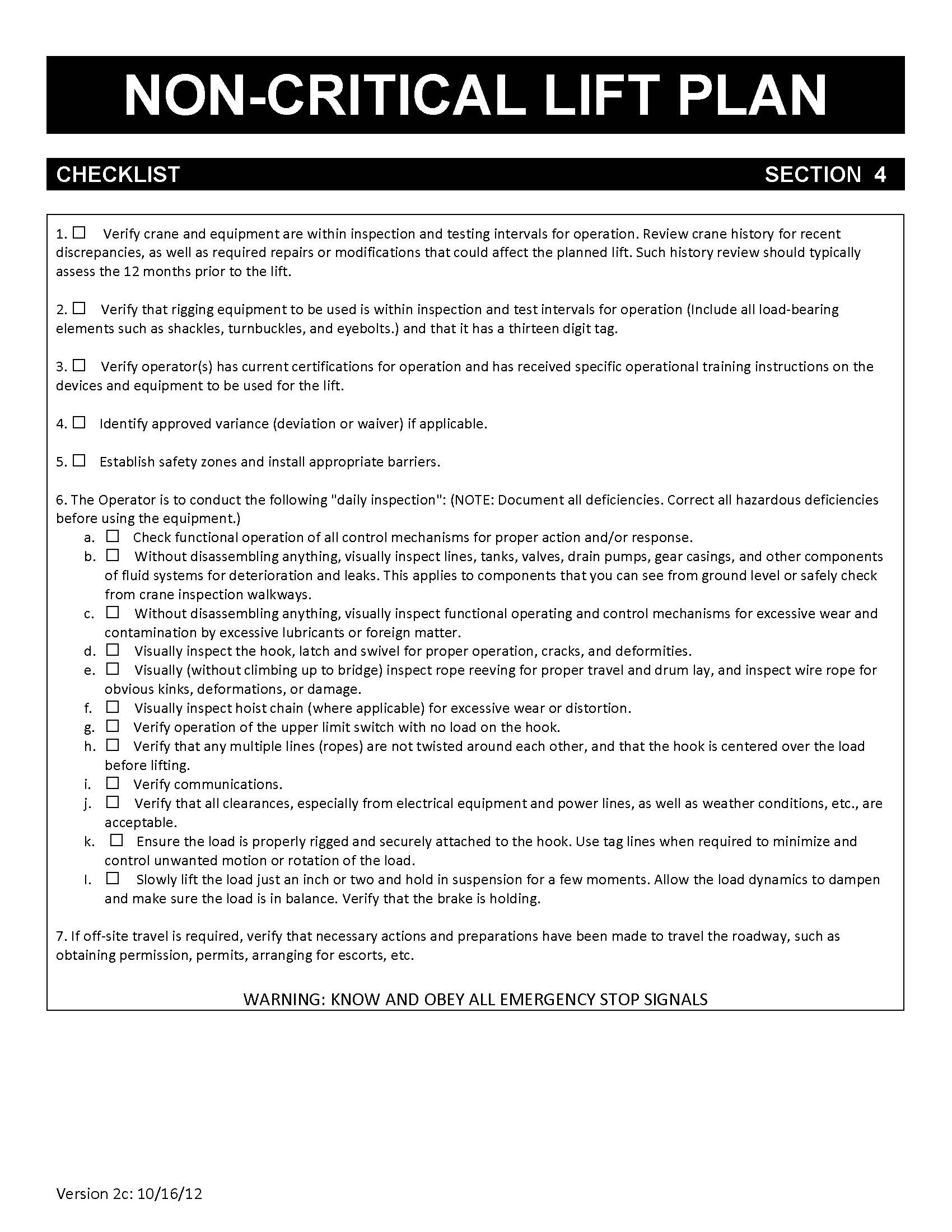

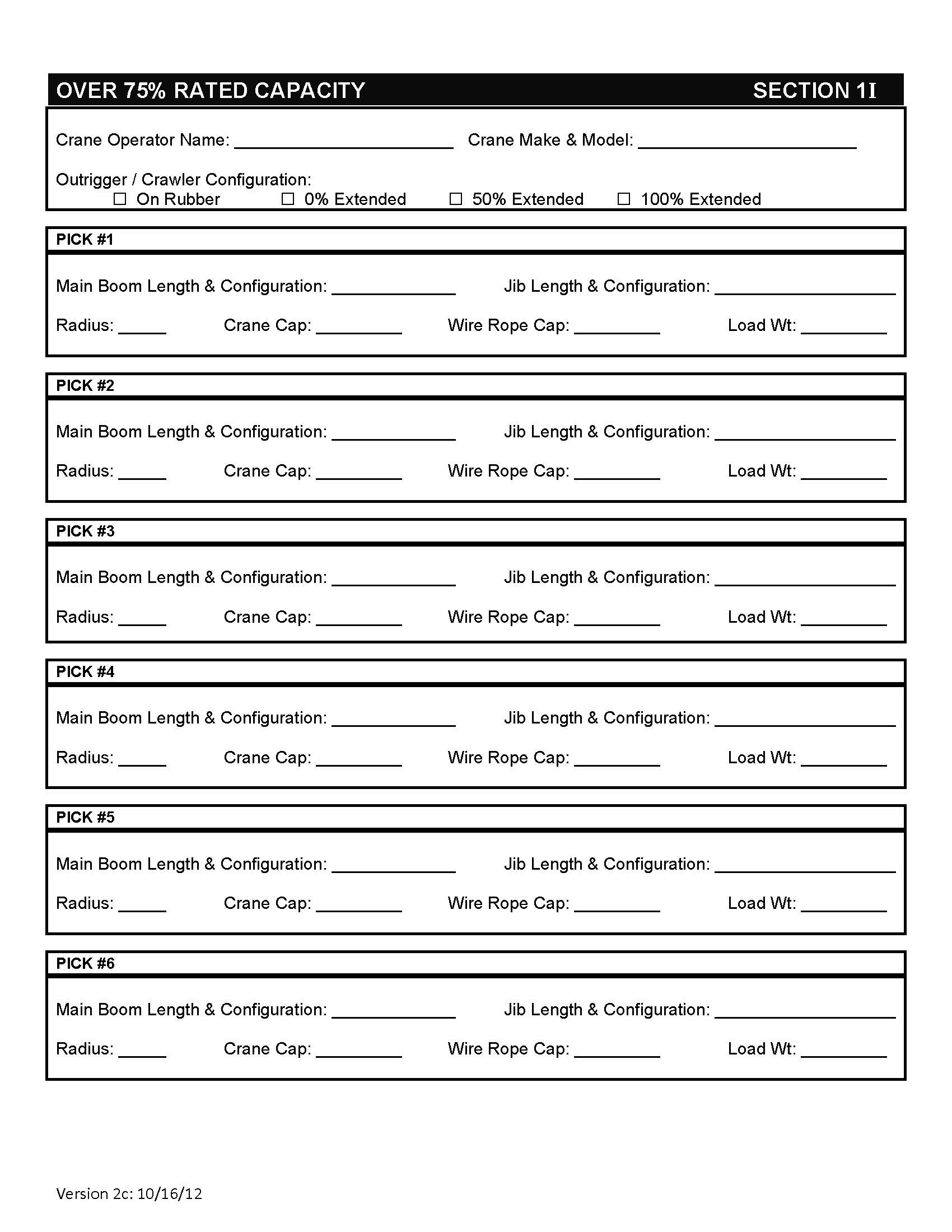

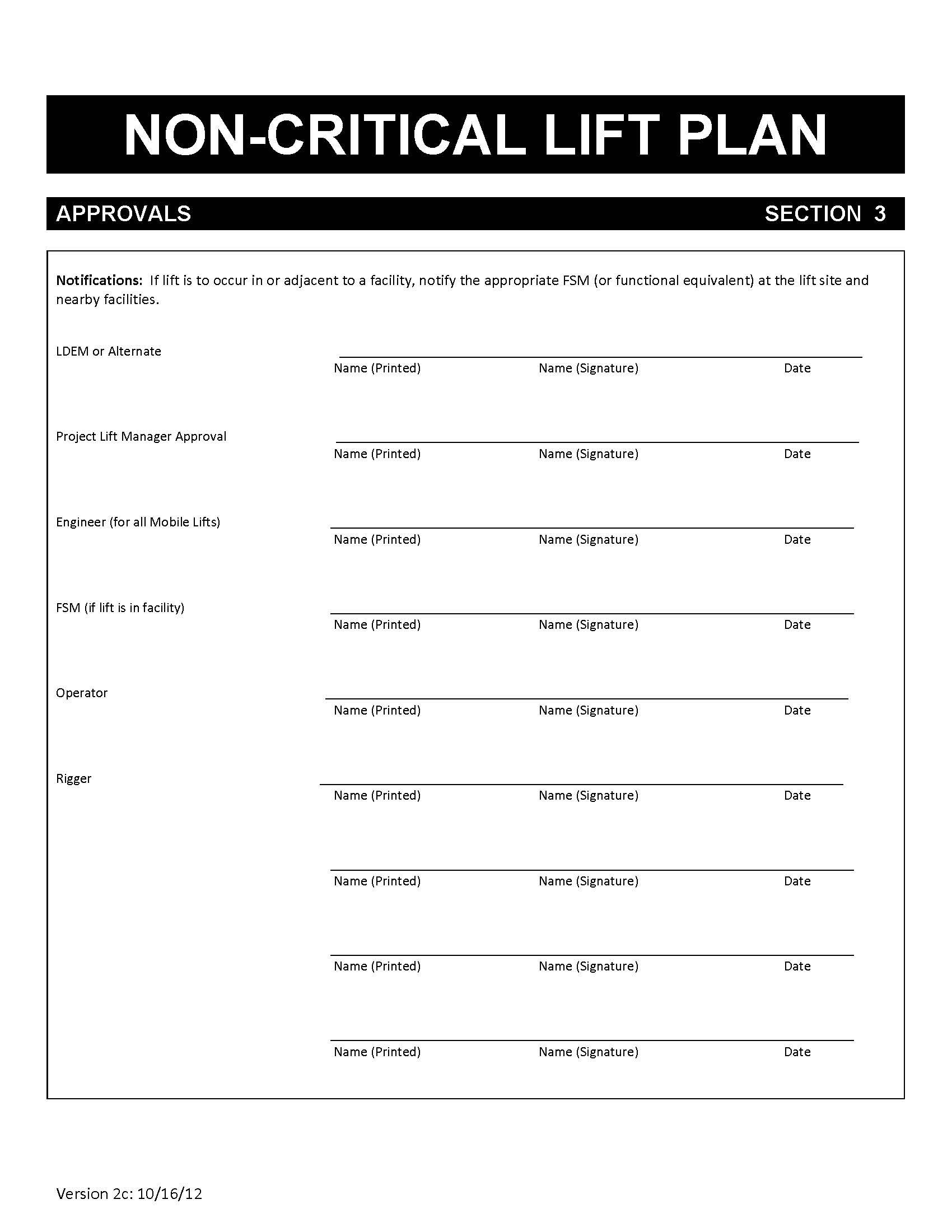

- Personnel working with Mobile Cranes, Derricks, Hoists & Winches will prepare a written lift plan using the Non-Critical Lift Plan form found in the Appendix five (5) days prior to the lift and then submit to the Construction Project Manager.

17.5.2 General Requirements for Hoists and Winches

- Personnel working with hoists and winches shall:

- Ensure that ropes are not handled on a winch head without the knowledge of the operator.

- Ensure that while a winch head is being used, the operator is within convenient reach of the power unit control lever.

17.5.3 Critical Lift Requirements for Mobile Cranes and Derricks

- Generally, high quality off-the-shelf, original equipment manufacturer (OEM) type equipment is acceptable for critical lifts if it is designed, maintained, and operated according to this standard.

- Testing:

- Mobile cranes are required to receive an annual periodic load test and an operational test the day of the lift. Rigging used for the lift are also required to receive an annual load test.

- Holding Brakes:

- Two (2) holding brakes are required, each capable of bringing a rated load to zero speed and holding it. The brakes are to be designed so that they can be tested as required in paragraph 5.3.3.f of NASA-STD-8719.9 (Standard for Lifting Devices and Equipment). This may be accomplished by the following means:

- When brakes and clutches are used to control the motion of the hoist drum, two independent means of braking are required to be provided which are a service brake and an emergency brake. The service brake is to be capable of functioning with power, and the emergency brake is to be set in the event of a power failure.

- For load hoists equipped with a mechanically linked hydraulic motor/brake combination, the use of a counterbalance valve that locks the hydraulic fluid when the valve is in the neutral position is an acceptable braking means. If a free fall clutch is present in the hoist design between the hydraulic motor and planetary disc, then a second independent holding or control brake is required.

- Operational Tests:

- The operational test for a modified crane/derrick can be tailored to test only those portions of the equipment that were modified, only if the periodic load and operational test interval has not expired. After a boom change on a crane/derrick used for critical lifts, the operational test does not have to include verification of each brake if it has been less than a year since the brakes were tested with a load equal to or greater than the maximum capacity of the crane/derrick with the new boom.

- Periodic Load Test:

- Cranes and derricks used for critical lifts are to be load tested at least once per year. A periodic load test is to be performed after each boom change (when boom disassembly/assembly is required) if the crane or derrick is to be used for critical lifts.

- Operation:

- The load is not to exceed seventy-five (75) percent of the rated capacity for the crane or derrick.

- Rented or Leased Cranes:

- If the lift is identified as a Critical Lift, NASA-STD-8719.9 (Standard for Lifting Devices and Equipment) will apply. If a rented or leased crane is operated by either a civil service employee or a ARC on-site contractor, that operator is to practice with a dummy load near capacity of the intended lift to get familiar with the unit.

- Pre-lift Safety Meeting:

- Each day of a Critical Lift, a Pre-Lift Safety meeting will be held with all lift participants. For pre-planned multiple lifts, a safety meeting is to be performed prior to each individual lift. The purpose of the meeting is to review the procedure, the hazards, the responsibilities of each team member, and the Critical Lift requirements. The following requirements are to be addressed:

- That Lift Plan will be followed as approved.

If changes are made in real time, the Lift Project Manager may approve changes in writing.

- Lift items will have tag lines at both ends for controllability.

- Hardhats and steel-toed boots are mandatory for all individuals.

- No unauthorized personnel may enter the exclusion zone.

- Gloves will be used as necessary, i.e., for holding tag lines.

- Personnel will not be located under suspended or moving loads unless the operation adheres to the OSHA-approved NASA alternative Standard for Suspended Load Operations. (See NASA-STD-8719.9 (Standard for Lifting Devices and Equipment), appendix A).

- Lifts over seventy-five (75) percent of the rated capacity of a mobile crane are not allowed for critical lifts.

- Documentation:

- A Critical Lift Procedure is to be completed whenever a Critical Lift is conducted at ARC or at an off-site location under ARC management (e.g., when on deployment). (See Appendix)

- A detailed Hazard Analysis of the Critical Lift operation is to be submitted by the Lift Project Manager.

- Submit the following documentation for review to the Safety, Health and Medical Services Division:

- Proof of crane operator medical clearance (NCCCO card is acceptable proof).

- Current operator license.

- Current training certification.

- Current crane inspection verification.

- Complete the Lift Determination form from the Appendix to determine if the lift is classified as critical or non-critical five (5) days prior to the lift and then submit to the Construction Project Manager.

- Prepare a written lift plan using the Critical Lift Plan form found in the Appendix five (5) days prior to the lift and then submit to the Construction Project Manager.

17.5.4 Load Test and Inspection Requirements for Mobile Cranes and Derricks

- There are three types of load tests required for mobile cranes and derricks.

- Before first use, all new, extensively repaired, extensively modified, or altered cranes and derricks are to undergo a proof load test. Mobile cranes and derricks are to be tested at the minimum practical working radius (and maximum working radius for new cranes and derricks only), without interfering with crane structure with a load as close as possible to, but not exceeding 1.10 times the rated load at the given radius. The load is to be lifted slowly and in an area where minimal damage will occur if the crane/derrick fails.

- Each mobile crane and derrick is to be tested at least once every four (4) years with a dummy load equal to the rated capacity of the crane or derrick at the minimum practical working radius, without interfering with crane structure, according to the manufacturer's load chart.

- Performed in conjunction with proof load and periodic load tests, the operational test typically moves the load through a full range of movement to determine if the equipment (limit switches, emergency stop controls, brakes, etc.) is functioning properly.

- The proof load tests and operational tests are to be performed prior to first use for new, extensively repaired, or altered cranes and derricks. This applies only to those components directly involved with the lifting or holding capability of a crane and derrick that has been repaired or altered. Repairs or alterations to nonlifting, secondary lifting, or holding components such as suspension assemblies, electrical system, or crane cab do not require a load test, although a functional check should be performed to determine if the repairs or alterations are acceptable.

- All load and operational tests are to be performed by qualified personnel according to written (specific or general) technical operating procedures. An inspection of the crane or derrick and lifting components is to be performed after each load test and prior to the crane or derrick being released for service to ensure there is no damage. Surface or volumetric NDT of critical components is required to validate the existence or absence of cracks or other load test effects indicated by this inspection. The periodic load test requirement may be fulfilled by a concurrently performed proof load test.

17.5.5 Inspection of Mobile Cranes and Derricks

- There are three types of inspections required for mobile cranes and derricks.

- These inspections are to be performed and documented prior to first use each day the crane or derrick is used, and kept on file in the area.

- Monthly Inspections (frequent inspections):

- These are formal inspections performed by qualified personnel.

- Annual inspections (periodic inspections):

- A formal annual inspection of the lifting components is performed by qualified personnel.

- After each formal inspection, qualified, authorized personnel are required to prepare written, dated, and signed inspection reports. These reports are to include a reference to the inspection procedure and adequacy of the crane and crane components. Inadequacies are to be documented and, if determined to be a hazard, corrected prior to further use. These reports are to be filed and made readily available by the organizational element responsible for inspection.

17.5.6 Inspection of Hoist Chains and Winches

- The following inspections shall be conducted:

- Daily or prior to use.

- Monthly inspections (called frequent in most organizations). These can also be formal inspections that are performed by the maintenance contractor.

- Annual inspections (also called periodic). These can also be formal inspections that are performed by qualified personnel.

17.5.7 Maintenance and Inspection Program

- Documentation of a program based on manufacturers' recommendations integrating proactive, reactive, preventative and predictive maintenance is required at NASA Ames.

- Mobile crane operators shall provide the following documentation at the lift site for verification:

- Daily inspection records.

- Crane certification.

- Maintenance service log or history.

- Proof of deficient condition correction.

17.5.8 Operator and Rigger Certification

- All operators of mobile cranes and riggers shall be trained and certified by a recognized certification organization that normally performs this function.

- Photocopy of card(s) are to be submitted with the lift plan.

- The physical card is to be carried at all times while at NASA Ames and presented upon request. Card is to clearly indicate renewal or expiration date not to exceed two (2) years from date of issue.

- Critical lifts require a more rigid operator certification program than those operations that involve routine lifts.

- In addition to the training, examination, licensing and license renewal requirements operators certified to perform critical lifts are to be trained in the specific hazards and special procedures associated with a critical lift.

- Operators must be immediately supervised by a critical lift certified operator during the initial lifting period.

17.5.9 NASA Alternate Standard for Suspended Load Operations

- NASA-STD-8719.9 contains an alternate standard for operations where employees may work under a suspended load. This standard applies to specifically identified operations controlled by NASA involving both civil service and contractor employees. The standard is an alternate to Code of Federal Regulations 29 CFR 1910.179(n)(3)(vi), 29 CFR 1910.180(h)(3)(vi), and 29 CFR 1910.180(h)(4)(ii).

17.5.10 Critical Lift Use for Hoists Chains and Winches

- All personnel working with chains and winches for critical lift use shall follow the requirements of NASA-STD-8719.9 (Standard for Lifting Devices and Equipment) section 6.2.7 i.

[Back to Table of Contents]

17.6 Powered Industrial Lift Trucks (Fork lifts)

- CAL OSHA General Industry Safety Order 3650 (Operating Rules) shall be conspicuously posted in a durable manner at each location within a building where Powered Industrial Lift Trucks are in operation.

- High quality off the shelf OEM-type equipment is acceptable for critical and non-critical lifts if it is designed, maintained, and operated according to this standard.

17.6.1 General Requirements

- Operators of Powered Industrial Lift Trucks shall:

- Follow the manufactures' recommendations and instructions.

- Follow OSHA CFR 1910.178, CAL OSHA General Industry Safety Order 3650 (Operating Rules), ANSI/ITSDF B56.1.

- Ensure that each type of powered industrial truck has an owners' manual readily available.

- Ensure they have been certified in the safe operation of powered industrial trucks.

- Ensure that prior to each use, a preoperational check is completed to ensure readiness of equipment and anticipated use.

- Ensure that a survey of the area of use has been completed for all hazards anticipated such as overhead, high voltage, holes, drop offs, depressions, mud, loose or un-compacted dirt, path of travel and any other hazardous condition. The operator may also establish exclusion zones by barricades if necessary.

- Ensure that all accidents are immediately reported involving equipment, personnel or building structures to supervisor.

- Ensure that they are wearing seatbelt at all times during operation.

- Ensure that PPE is available and worn when a hazard is present.

- A powered industrial truck is considered unattended if out of the operators' view or the operator is MORE than 25 feet away regardless of being in the operators' view.

- Perform a safety hazard analysis such as fault tree analysis, FMEA, O&SHA for industrial trucks that are used for lifts where failure/ loss of control could result in loss or damage to flight hardware. The safety hazard analysis it to include at a minimum:

- Determine potential sources of danger.

- Identity failure modes and recommended resolutions with a system of risk acceptance for those conditions found in the hardware-facility-environment-human relationship that could cause loss of life, personal injury and loss of/or damage to the powered industrial truck, facility or load.

- Critical lifts are lifts where failure/loss of control could result in loss of life, loss of or damage to flight hardware or lifts involving special, such as spacecraft, one-of-a-kind articles, or major facility components whose loss would have serious programmatic or institutional impact. Critical lifts also include the lifting of personnel, lifts where personnel are required to work under a suspended load and operations with special personnel and equipment safety concerns beyond normal lifting hazards.

17.6.2 General Requirements for Critical Lifting Operations

- All personnel involved in critical lifting operations shall:

- Prepare and follow specific written procedures.

- Ensure one qualified person (NASA employee or contractor) is officially designated as responsible for the safety of the operations. That person may be a safety professional, a supervisor, an engineer or a task leader. This person is designated at the Safety Lift Observer (SLO).

- Ensure that powered industrial trucks used to lift or support flight hardware are labeled and tagged as specified in NASA-STD-8719.9 (Standard for Lifting Devices and Equipment).

- Ensure that powered industrial trucks are operated or used as specified in this chapter and NASA-STD-8719.9 (Standard for Lifting Devices and Equipment).

- Identify all hazards to include operations, maintenance, equipment, facility, anticipated loads, and human factors.

- Ensure that all critical lift documentation is completed and signed prior to operation.

17.6.3 Load Test Requirements

- Three types of tests are required for Powered Industrial Lift Trucks:

- Proof load test: prior to first use, all new, extensively repaired or altered powered industrial lift trucks in accordance with the manufactures instructions and applicable AMSE standard.

- Periodic load test: conducted annually with a load equal to the rated load. See Table 3 for Periodic Load Test Factors.

- Operational tests: conducted simultaneously with proof test with a dummy rated load unless otherwise specified.

17.6.4 Inspection Requirements

- Three types of inspections are required for Powered Industrial Lift Trucks:

- Initial prior to being placed into service.

- Daily or prior to use.

- Periodic inspections performed by a qualified person at least annually or according to manufactures' recommendation and/or ASME B56.1 and severity of service, environment.

- All Powered Industrial Lift trucks shall have a legible data plate showing the capacity in English or Universal weight measurements.

- Document any deficiency found during the pre-operational inspection and remove from service using administrative locking until steps are taken to correct deficiency.

17.6.5 Design Features

- Minimum operational and design features for lift trucks (on road and off road) shall include:

- A load backrest will be so installed to prevent loads from falling back and to cradle loads when traveling.

- Overhead guards will be installed to protect against falling objects hitting operators.

- Attachments have to be treated as part of the load and authorized by the manufacturer.

[Back to Table of Contents]

17.7 Aerial Lift Platforms

- Includes: Scissor Lift, Boom Lift, Articulating, Truck Mounted.

- Only high quality off the shelf OEM type equipment will be used if it is maintained, designed and operated to the requirements in NASA-STD-8719.9 (Standard for Lifting Devices and Equipment).

- Shall not be used as cranes.

- Three types of tests are required for mobile and aerial platforms:

- Proof load test: prior to first use, all new, extensively repaired or altered mobile aerial platforms in accordance with the manufactures instructions and applicable American National Standards Institute/Scaffold Industry Association (ANSI/SIA) standard.

- Periodic load test: conducted annually with a load equal to the rated load.

- Operational tests: conducted simultaneously with proof test and a dummy rated load unless otherwise specified.